Izinhlobo eziyinhloko zama-flange gaskets

Ama-gasket angewona awensimbi

Izinto ezijwayelekile: irabha, i-polytetrafluoroethylene (PTFE), i-fiber engeyona i-asbestos (i-asbestos yerabha).

Ukusetshenziswa okuyinhloko nezici:

Ama-gasket e-asbestos enjoloba ayesetshenziswa kabanzi emanzini, emoyeni, emusi, e-asidi kanye nakuma-alkali media, ayeyinketho evamile.

Ama-gasket e-asbestos enjoloba ayesetshenziswa kabanzi emanzini, emoyeni, emusi, e-asidi kanye nakuma-alkali media, ayeyinketho evamile.

Ezimweni ezingamelani nokugqwala, ama-gasket e-PTFE anokuqina okuhle kwamakhemikhali.

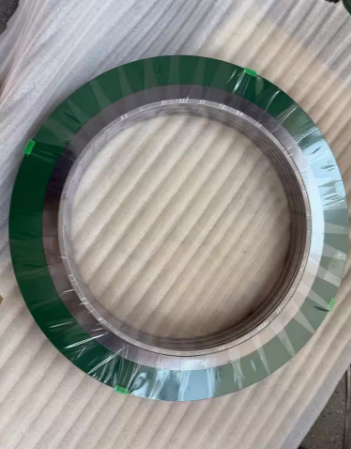

Ama-gasket e-semi-metallic

Izinto ezijwayelekile: Ibhendi yensimbi + i-graphite/asbestos/ibhendi egcwele i-PTFE (uhlobo lwesilonda), umongo ongeyona insimbi ombozwe ngensimbi, i-gasket ehlanganisiwe ye-graphite eguquguqukayo.

Ukusetshenziswa okuyinhloko nezici:

Ukuhlanganisa amandla ensimbi kanye nokuqina kwensimbi engeyona eyensimbi ezimweni zokusebenza ezishisa kakhulu, ezinomfutho ophezulu kanye neziguquguqukayo. Phakathi kwazo, ama-gasket ensimbi ayizinqumo eziyinhloko embonini ye-petrochemical, yamakhemikhali kanye neminye.

Ngezidingo eziqinile zokuvala, njengezinsimbi ezigobile/ezinamagasket endandatho, zisetshenziswa emapayipini noma emithonjeni yokucindezela enengcindezi ephezulu kanye nokushisa.

Ama-gasket ensimbi

Izinto ezijwayelekile: insimbi ethambile, insimbi engagqwali, ithusi, i-Monel alloy.

Izinhlelo zokusebenza eziyinhloko nezici:

Izimo ezimbi kakhulu: ezisetshenziswa ezindaweni ezishisa kakhulu, ezinomfutho ophezulu kanye nezingcolisa kakhulu.

Zinikeza ukusebenza okuhle kakhulu kokuvala kodwa zinezidingo eziphezulu kakhulu zokunemba kokucutshungulwa kwendawo yokuvala i-flange kanye nokufakwa kwayo, futhi ziyabiza kakhulu.

Uma ukhetha ama-gasket, kunezinto eziningi okudingeka zicatshangelwe ngokuphelele. Ingqikithi ilele emaphuzu amane abalulekile: “okuphakathi, ingcindezi, izinga lokushisa, kanye ne-flange“.

Izakhiwo Eziphakathi: Ukuze kube nezinto ezigqwalisayo (ezifana nama-asidi nama-alkali), izinto ze-gasket kumele zingagqwali.

Ingcindezi yokusebenza kanye nokushisa: Ezimweni zokushisa okuphezulu kanye nokucindezela okuphezulu, ama-gasket ensimbi noma angensimbi angakwazi ukumelana nokushisa kanye nokucindezela kumele akhethwe.

Uhlobo lobuso bokuvala i-Flange: Izindawo ezahlukene ze-flange (njenge-RF yobuso obuphakanyisiwe, i-MFM yobuso besilisa nabesifazane, i-tongue and groove face TG) kumele zihambisane nezinhlobo ezithile ze-gasket.

Ezinye izici: Ukudlidliza, ukushintshashintsha njalo kwezinga lokushisa kanye nengcindezi, isidingo sokuqaqwa njalo, kanye nesabelomali sezindleko nakho kumele kucatshangelwe.

Sekukonke,

Ngokucindezela okuphansi kanye nemidiya evamile (amanzi, umoya, umusi onomfutho ophansi): Ama-gasket angewona awensimbi, njengerabha noma ama-gasket e-PTFE, ayathandwa ngenxa yokuthi asebenza kahle kakhulu.

Ezimweni zokusebenza ezicindezelayo eziphakathi kuya kweziphezulu, izinga lokushisa eliphezulu noma eziyinkimbinkimbi (amapayipi embonini kaphethiloli, amakhemikhali kanye namandla): Ama-gasket angensimbi, ikakhulukazi ama-gasket anenxeba lensimbi, ayisinqumo esivame kakhulu nesithembekile.

Uma izinga lokushisa eliphezulu kakhulu kanye nengcindezi noma izimo ezigqwalisayo ezinamandla: Ama-gasket ensimbi (njenge-corrugated noma i-ring gaskets) kufanele acatshangelwe, kodwa kubalulekile ukuqinisekisa ukuhambisana kahle kwe-flange kanye nokufakwa okufanele.

https://www.czitgroup.com/stainless-steel-graphite-packing-spiral-wound-gasket-product/?fl_builder

Isikhathi sokuthunyelwe: Jan-15-2026