Izindololwane Ezingenamthungo Zensimbi Yekhabhoni Eziphansi Ezingenakushisa

Njengoba zenzelwe isevisi ebalulekile ezindaweni ezishisayo nezishisayo, ama-Elbow ethu e-Carbon Steel Low-Temperature Seamless Elbows akhiqizwa ngezinto ezisezingeni eliphezulu njenge-API 5L X65 noma insimbi ekhethekile ye-ASTM A333 Grade 6. Atholakala kokubili ekulungiselelweni okungu-90° no-180° nge-1.5D Long Radius ejwayelekile, lawa ma-butt weld elbows aklanyelwe ukugcina ukuqina okumangalisayo kanye nobuqotho besakhiwo ngaphansi kwezimo eziphansi kakhulu, ukuvimbela ukuphuka okubuthakathaka ezinhlelweni ezifana nokucubungula i-LNG, isitoreji se-cryogenic, kanye nezinhlelo zamapayipi e-arctic.

Njengoba zenziwe ngenqubo yokwakha ukushisa engenamthungo, lezi zindololwane zinikeza ukuqhubeka okuphezulu kwensimbi kanye nobuqotho bengcindezi uma kuqhathaniswa nezinye ezihlanganisiwe. Irediyasi yokugoba engu-1.5D iqinisekisa ukugeleza okubushelelezi nge-turbulence encane kanye nokwehla kwengcindezi, kuyilapho ukulungiswa kwe-weld bevel okunembile kuqinisekisa ukugoqa kwensimu okuseqophelweni eliphezulu, okugcwele ukungena. Lezi zingxenye ziyisinqumo esithembekile sonjiniyela abaklama izinhlelo zamapayipi eziphephile neziqinile okumele zisebenze ngokuthembekile kusukela endaweni ezungezile kuya emazingeni okushisa abandayo.

AMAPHARAMETHI OMKHIQIZO

| Igama Lomkhiqizo | Ingqiniba yepayipi |

| Usayizi | Ingqiniba engenamthungo engu-1/2"-36" (ingqiniba ye-SMLS), engu-26"-110" ihlanganiswe ngomthungo. Ububanzi obukhulu bangaphandle bungaba ngu-4000mm |

| Okujwayelekile | I-ANSI B16.9, EN10253-2, DIN2605, GOST17375-2001, JIS B2313, MSS SP 75, njll. |

| Ubukhulu bodonga | I-STD, i-XS, i-XXS, i-SCH20, i-SCH30, i-SCH40, i-SCH60, i-SCH80, i-SCH160, i-XXS njll. |

| Idigri | 30° 45° 60° 90° 180°, njll. |

| Irediyasi | Irediyasi ye-LR/endeshi/R=1.5D, Irediyasi ye-SR/endeshi emfushane/R=1D |

| Ukuphela | Isiphetho se-Bevel/BE/buttweld |

| Ubuso | umbala wemvelo, i-varnished, upende omnyama, uwoyela wokulwa nokugqwala njll. |

| Izinto | Insimbi yekhabhoni:I-A234WPB, A420 WPL6 St37,St45, E24, A42CP, 16Mn, Q345, P245GH,P235GH, P265GH, P280GH, P295GH, P355GH njll. |

| Insimbi yepayipi:I-ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65, WPHY70, WPHY80 njll. | |

| Insimbi ye-Cr-Mo alloy:A234 WP11, WP22, WP5, WP9, WP91, 10CrMo9-10, 16Mo3, 12crmov, njll. | |

| Isicelo | Imboni ye-Petrochemical; imboni yezindiza kanye nezindiza; imboni yezemithi, igesi ephumayo; isitshalo samandla; isakhiwo semikhumbi; ukwelashwa kwamanzi, njll. |

| Izinzuzo | isitoko esilungile, isikhathi sokulethwa esisheshayo; sitholakala ngosayizi bonke, senziwe ngokwezifiso; ikhwalithi ephezulu |

IZINTO ZOKWENZA AMAPHAYIPHI

Ukufakwa kwamapayipi ahlanganisiwe ngezinqe kufaka phakathi indololwane yepayipi yensimbi, i-tee yepayipi yensimbi, i-reduer yepayipi yensimbi, i-cap yepayipi yensimbi. Zonke lezo zingxenye zamapayipi okushisela izinqe, singazihlinzeka ndawonye, sinolwazi lokukhiqiza lweminyaka engama-20.

Uma unesithakazelo nakwezinye izinto zokufakelwa, sicela uchofoze ku-LINK elandelwayo ukuze uhlole imininingwane.

I-PIPE TEE ISINCISHISI SAMAPHAYIPHI ISIVALO SEPAYIPHI UKUGOBA KWEPIPI IZINTO EZIFAKWE NGOKUQINISEKISA

I-BUTT WLDED PIPE ELBOW

I-elbow yepayipi lensimbi iyizingxenye ezibalulekile ohlelweni lwamapayipi ukushintsha indlela yokugeleza koketshezi. Isetshenziselwa ukuxhuma amapayipi amabili anobubanzi obufanayo noma obuhlukile, nokwenza ipayipi liphendukele ohlangothini oluthile lwama-degree angu-45 noma angu-90.

Kumapayipi endololwane ezimbonini, uhlobo lwe-connectin end luyi-butt weld, ngokusho kwe-ANSI B16.25. I-Butt weld ingachaza i-butt welding, i-butweld, ne-bevel end. BW

UHLOBO LWESIBANDLA

Ingqiniba ingahle ihluke kusukela ekhoneni eliqondisiwe, izinhlobo zokuxhuma, ubude kanye nerediyasi, izinhlobo zezinto.

Kuhlukaniswe nge-Direction Angle

Njengoba sazi, ngokwesiqondiso soketshezi samapayipi, indololwane ingahlukaniswa ngamadigri ahlukene, njenge-degrees ezingama-45, 90, 180, okuyizingadi ezivame kakhulu. Futhi kune-degrees ezingama-60 kanye ne-120, kwamanye amapayipi akhethekile.

Ngendololwane engama-degree angu-90, kuchazwe nendololwane engama-90d, noma indololwane engama-degree angu-90.

Iyini i-Elbow Radius

Irediyasi yendololwane isho irediyasi egobile. Uma irediyasi ifana nobubanzi bepayipi, ibizwa ngokuthi i-short radius elbow, ebizwa nangokuthi i-SR elbow, ngokuvamile yamapayipi anengcindezi ephansi kanye nesivinini esiphansi.

Uma i-radius inkulu kunobubanzi bepayipi, i-R ≥ 1.5 Diameter, khona-ke siyibiza ngokuthi i-long radius elbow (LR Elbow), esetshenziselwa amapayipi okucindezela okuphezulu kanye nesivinini sokugeleza okuphezulu.

Uma irediyasi ingaphezu kuka-1.5D, njalo ibizwa ngokuthi ukugoba. Ukugoba kwendololwane kufanele kufakwe kumapayipi. Njengendololwane engu-2d, ukugoba okungu-2d, indololwane engu-3d, ukugoba okungu-3d, njll.

Ukuhlukaniswa Ngokwezinto Ezibalulekile

Insimbi yekhabhoni, ebizwa nangokuthi insimbi emnene noma insimbi emnyama. Njenge-ASTM A234 WPB

Uma ufuna izindololwane zensimbi engagqwali, sicela uchofoze lesi sixhumanisi ukuze uthole imininingwane eyengeziwe:IZINDLOVU ZENSITI ENGAGQI

Uhlobo Lomumo

Kungaba yindololwane elinganayo noma Ukunciphisa indololwane

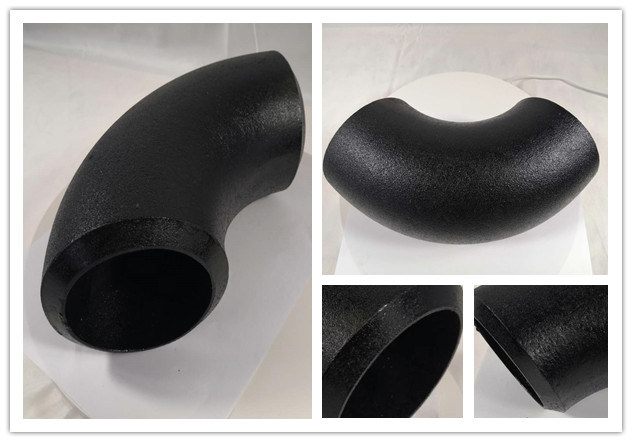

UBUSO BE-ELBOW

Ukuqhuma Kwesihlabathi

Ngemva kokwakheka okushisayo, sihlela ukuqhuma kwesihlabathi ukuze senze indawo ihlanzeke futhi ibushelelezi.

Ngemva kokuqhuma kweSand, ukuze kugwenywe ukugqwala, kufanele upende omnyama noma uwoyela wokulwa nokugqwala, i-Hot dip galvanized (HDG), i-epoxy, i-3PE, indawo enyamalele, njll. Lokho kuncike esicelweni sekhasimende.

Izinto kanye ne-Metallurgy:

Izindololwane zenziwe ngepayipi elingenamthungo eliqinisekiswe yi-API 5L X65 ukuze kusetshenziswe amandla aphezulu noma i-ASTM A333 Grade 6 ukuze kutholakale izakhiwo eziqinisekisiwe zomthelela wokushisa okuphansi. Lezi zinsimbi zinohlamvu oluncane, zibulawe ngokuphelele, futhi zivame ukwenziwa zibe zijwayelekile ukuze kufezwe amanani adingekayo wamandla omthelela we-Charpy V-Notch (CVN) ekushiseni okuncane okubekiwe. I-chemistry ilawulwa ukuze kukhawulelwe izinto ezikhuthaza ukuphuka, kuqinisekiswe ukuqina okuhle kakhulu kokuqhekeka ezindaweni ezibandayo.

Inqubo Yokukhiqiza Engenamthungo:

Izindololwane zakhiwa ngokusebenzisa ukugoba okulawulwayo kokufakwa kokushisa kwepayipi elingenamthungo noma inqubo yokusunduza eshisayo. Zombili lezi zindlela zigcina ukulingana kwezinto ngaphandle kokudala umthungo oqondile. Ngemva kokwakheka, izindololwane zithola ukwelashwa kokushisa okuvamile ukuze kulungiswe isakhiwo sezinhlamvu, kuncishiswe ukucindezeleka, futhi kubuyiselwe izakhiwo zemishini ezibalulekile ekusebenzeni kwezinga lokushisa eliphansi.

Ubunjiniyela Bokunemba Nobukhulu:

Kwenziwe ngokuqinile ngokuvumelana ne-ASME B16.9 tolerances.

Ubukhulu obuphakathi nendawo/phakathi nendawo: Kulawulwa ngokunembile ukuze kube nokuhlelwa kwamapayipi okunembile.

Ukulawula Ubukhulu Bodonga: Le nqubo iqinisekisa ukujiya okufanayo. Kunakekelwa ngokukhethekile ama-extrados (ukugoba kwangaphandle) ukuze kugcinwe ukujiya ngaphakathi kwemingcele evumelekile ye-ASME B16.9 (ngokuvamile umkhawulo ongu-12.5%).

Ukungaguquguquki Nokugqama: Iziphetho zenziwa ngomshini ukuqinisekisa ukuthi zigobile ukuze zilingane kahle. I-bevel yokushisela engu-37.5° ehambisanayo enezwe elingu-1.6mm ilungiswa kuzo zombili iziphetho.

Ukumaka Nokulandelela:

Ingqiniba ngayinye igxivizwa unomphela ngokwe-ASTM A960, okuhlanganisa: Ukucaciswa Kwezinto (isb., i-API 5L X65 noma i-A333 Gr.6), Inombolo Yokushisa, Usayizi, Ishejuli Yodonga, I-ID Yomkhiqizi, kanye nesibonakaliso "se-LT" (Izinga Lokushisa Eliphansi). Lokhu kuqinisekisa ukulandeleka okugcwele kusukela emshinini wensimbi kuya kumkhiqizo oqediwe.

UKWELASHWA NGOKUSHISA

1. Gcina isampula yezinto zokusetshenziswa ukuze ulandelele.

2. Hlela ukwelashwa kokushisa ngokwezinga elijwayelekile.

UKUPHAWULA

Imisebenzi ehlukahlukene yokumaka, ingagoba, ipendwe, ibhalwe phansi. Noma ngesicelo sakho. Siyakwamukela ukumaka i-LOGO yakho.

IZITHOMBE EZINEMINININGWANE

1. Isiphetho se-Bevel ngokwe-ANSI B16.25.

2. Ukuqhuma kwesihlabathi kuqala, bese kuba umsebenzi omuhle wokupenda. Kungafakwa i-varnish.

3. Ngaphandle kwe-lamination kanye nemifantu.

4. Ngaphandle kokulungiswa kokushisela.

UKUHLOLA

Ukushisa ngakunye kwensimbi kunikezwa isitifiketi esiphelele sokuhlolwa kwe-Mill (MTC 3.2) esichaza amakhemikhali kanye nezakhiwo zemishini. Senza ukuhlolwa kobukhulu be-Positive Material Identification (PMI) kanye ne-ultrasonic kuphayiphi eluhlaza. Ukuqinisekiswa okuyinhloko yi-Charpy V-Notch Impact Testing nge-ASTM A370. Amasethi amasampula amathathu ahlolwa ngokushisa okuncane komklamo (isb., -46°C) ukuqinisekisa ukuthi amandla adonswayo ahlangabezana noma adlula izidingo ezibekiwe (isb., ≥ 20J noma 27J nge-ASTM A333).

UKUPHAKISHA NOKUTHUMELA

Ukuze kuvinjelwe ukugqwala ngesikhathi sokuhamba, iziphetho ezigobile kanye nezindawo eziveziwe zimbozwa nge-rust yesikhashana, esuswa kalula. Ingqiniba ngayinye ibe isisongwa ngefilimu ye-VCI (Vapor Corrosion Inhibitor) noma ngepulasitiki esindayo. Ezingqinibeni ezisindayo noma ezinkulu, kusetshenziswa ama-cradle okhuni noma ama-cradle enziwe ngokwezifiso ukuhlinzeka ngokusekelwa kwesakhiwo nokuvimbela ukuguguleka.

Sisebenzisa izindlela ezahlukene ngokusekelwe kusayizi we-oda kanye nokuphuthuma: ukuthunyelwa ngendiza kwezinto ezibalulekile ezisheshayo, isitsha sasolwandle (i-FCL/LCL) sama-oda amaningi, kanye nezitsha ezisicaba zezindololwane ezinkulu. Yonke imibhalo yokuthumela (Uhlu Lokupakisha, I-invoyisi Yezentengiselwano, Isitifiketi Sokuqala, kanye Nephakheji Yokuhlola Egcwele) ilungiselelwe ukwenza kube lula ukususwa kwempahla yamasiko kumaphrojekthi ezimboni emhlabeni jikelele.

Isicelo

Uwoyela negesi (i-Arctic kanye ne-Offshore):

Amapayipi angaphansi kolwandle, amapulatifomu okukhiqiza angaphandle kolwandle ezindaweni ezibandayo, kanye nezinhlelo zokuqoqana ogwini lolwandle ezindaweni ezibandayo.

Imboni ye-LNG (igesi yemvelo encibilikisiwe):

Amabhokisi abandayo, imigqa yenqubo yokuncibilikisa uketshezi, imigqa yokudlulisa i-LNG, kanye namapayipi ethangi lokugcina izinto asebenza emazingeni okushisa aphansi.

Ukucubungula kwe-Cryogenic:

Izitshalo zegesi zezimboni (ukuhlukaniswa kwe-O2, i-N2, i-Ar), izitshalo ze-ethylene, kanye namapayipi okuthutha e-CO2.

Amandla kanye namakhemikhali:

Imigqa yokucubungula ezindaweni ezisendaweni ebanda kakhulu.

Ubuchwepheshe ezintweni ezisezingeni lokushisa eliphansi:

Sinolwazi olujulile ezicinisweni, ekuhlolweni nasekuphathweni kwezinsimbi zekhabhoni ezisezingeni eliphansi lokushisa, ukuqinisekisa ukuthi umkhiqizo unikeza ukusebenza okuqinisekisiwe.

Ukugxila Kokukhiqiza Okungenamthungo:

Ukuzibophezela kwethu ekukhiqizeni okungenamthungo kuqinisekisa ubuqotho obuphezulu bensizakalo ebalulekile ye-cryogenic lapho amaphutha okushisela engamukeleki.

Iphakheji Yesitifiketi Esiphelele:

Sinikeza amadokhumenti aqinile kakhulu embonini, ikakhulukazi i-Charpy Impact Test Reports eqinisekisiwe, ebalulekile ekuvunyelweni kobunjiniyela kanye nokuhlolwa kokuphepha kumaphrojekthi asezingeni eliphansi lokushisa.

Ukwenza Ngokwezifiso Okusekelwe Kuphrojekthi:

Sihlela imikhiqizo ngokwezidingo ezithile zephrojekthi, okuhlanganisa osayizi abakhethekile, amazinga okushisa okuhlolwa komthelela athuthukisiwe, kanye ne-NDT eyengeziwe, sikhonza ngqo osonkontileka be-EPC kanye nabasebenzisi bokugcina.

I-Global Logistics Yengqalasizinda Ebalulekile: Singabalingani abanolwazi kumaphrojekthi amakhulu wamandla, siqinisekisa ukuthi lezi zingxenye ezikhethekile neziqinisekisiwe zilethwa ngesikhathi esibekiwe ezindaweni ezikude noma ezidinga kakhulu, zisekelwa ukulandelelwa okuphelele kanye nemibhalo yekhwalithi.

Ukufakwa kwamapayipi kuyizinto ezibalulekile ohlelweni lwamapayipi, ezisetshenziselwa ukuxhuma, ukuqondisa kabusha, ukuphambukisa, ukushintsha usayizi, ukuvala noma ukulawula ukugeleza koketshezi. Zisetshenziswa kabanzi emikhakheni efana nokwakha, imboni, amandla kanye nezinsizakalo zikamasipala.

Imisebenzi Eyinhloko:Ingenza imisebenzi efana nokuxhuma amapayipi, ukushintsha indlela yokugeleza, ukuhlukanisa nokuhlanganisa ukugeleza, ukulungisa ububanzi bamapayipi, ukuvala amapayipi, ukulawula nokulawula.

Ububanzi Bokusetshenziswa:

- Ukwakhiwa kwamanzi kanye nokukhipha amanzi:Izindololwane ze-PVC kanye ne-PPR tris zisetshenziselwa amanethiwekhi amapayipi amanzi.

- Amapayipi ezimboni:Ama-flange ensimbi engagqwali kanye nezindololwane zensimbi ezixutshwe ngomlotha zisetshenziselwa ukuthutha izinto zamakhemikhali.

- Ukuthuthwa kwamandla:Izithako zamapayipi ensimbi anomfutho ophezulu zisetshenziswa emapayipini kawoyela negesi.

- I-HVAC (Ukushisa, Umoya Ongenisayo, kanye Nomoya Ongenisayo):Izithako zamapayipi ethusi zisetshenziselwa ukuxhuma amapayipi efriji, kanti amalunga aguquguqukayo asetshenziselwa ukunciphisa ukudlidliza.

- Ukunisela ngenkasa kwezolimo:Izixhumi ezisheshayo zenza kube lula ukuhlanganiswa nokuhlukaniswa kwezinhlelo zokunisela ezifafaza.

-

I-ANSI b16.9 isheduli engamasentimitha angu-36 i-Weld carbon engu-40 Butt...

-

I-Asme b16.9 schedule 80 steel pipe fittings tee ...

-

insimbi yekhabhoni engu-45 degree bend 3d bw 12.7mm WT AP...

-

Izithako zepayipi ze-SUS304 316 Ingqiniba yensimbi engagqwali ...

-

I-ANSI B16.9 Insimbi Yekhabhoni Egobile Ngamadigri angu-45 Ukugoba Kokushisela

-

I-ANSI B16.9 butt weld Pipe Fitting carbon steel ...