IMIPHAKATHI YOMKHIQIZO

| Igama Lomkhiqizo | Indololwane yepayipi |

| Usayizi | 1/2"-36" indololwane engenamthungo(indololwane ye-SMLS), 26"-110" eshiselwe ngomthungo.Ububanzi obukhulu bangaphandle bungaba ngu-4000mm |

| Okujwayelekile | ANSI B16.9, EN10253-2, DIN2605, GOST17375-2001, JIS B2313, MSS SP 75, njll. |

| Ukujiya kodonga | STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS nokunye. |

| Iziqu | 30° 45° 60° 90° 180°, njll |

| Irediyasi | LR/irediyasi ende/R=1.5D,SR/Irediyasi emfushane/R=1D |

| Qeda | I-Bevel end/BE/buttweld |

| Ubuso | umbala wemvelo, i-varnished, umdwebo omnyama, uwoyela ophikisana nokugqwala njll. |

| Okubalulekile | Insimbi ye-Carbon:I-A234WPB, A420 WPL6 St37,St45, E24, A42CP, 16Mn, Q345, P245GH,P235GH, P265GH, P280GH, P295GH, P355GH njll. |

| Insimbi yepayipi:ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65,WPHY70, WPHY80 nokunye. | |

| Insimbi ye-Cr-Mo ingxubevange:I-A234 WP11, WP22, WP5, WP9, WP91, 10CrMo9-10, 16Mo3 , 12crmov, njll. | |

| Isicelo | Imboni ye-petrochemical;imboni yezindiza kanye ne-aerospace;imboni yezemithi,i-gas exhaust;isikhungo sikagesi;isakhiwo somkhumbi;ukwelashwa kwamanzi, njll. |

| Izinzuzo | isitoko esilungile, isikhathi sokulethwa esisheshayo; sitholakala kuwo wonke amasayizi, enziwe ngokwezifiso; ikhwalithi ephezulu |

UKUFAKELWA KWAMAPHOPHA

Ukufakwa kwepayipi elishiselwe izinqe kuhlanganisa indololwane yepayipi lensimbi, i-steel pipe tee, i-steel pipe reduer, ikepisi yepayipi lensimbi.Zonke lezo butt welding pipe nokufakwa, singakwazi ukuhlinzeka ndawonye, sineminyaka engaphezu kwengu-20 nakho ukukhiqiza.

Uma unentshisekelo yokunye ukufakwa, sicela uchofoze kulandelwe LINK ukuze uhlole imininingwane.

I-PIPE TEE I-PIPE REDUCER I-PIPE CAP I-PIPE GOBA IZINTO EZIFAKELWE

IBHAYIBHANA ELISHISHISELWE IBHAYIBHANA

Indololwane yepayipi lensimbi iyizingxenye ezibalulekile ohlelweni lwamapayipi ukuze kushintshwe indlela yokugeleza koketshezi.Isetshenziselwa ukuxhuma amapayipi amabili anobubanzi obufanayo noma obuhlukile, nokwenza ipayipi iphendukele ohlangothini oluthile lwama-degree angu-45 noma angu-90.

Ngendololwane yepayipi yezimboni, uhlobo lokugcina lwe-connectin luyi-butt weld, ngokusho kwe-ANSI B16.25.Izinqe ezishiselwe zingachaza i-butt welding, i-buttweld, i-bevel end.BW

UHLOBO LWENDLOVU

Indololwane ingahlukaniswa ukusuka ku-engeli yokuqondisa, izinhlobo zokuxhuma, ubude ne-radius, izinhlobo zezinto ezibonakalayo.

Kuhlukaniswa nge-Direction Angle

Njengoba sazi, ngokusho kwesiqondiso samanzi samapayipi, indololwane ingahlukaniswa ngamadigri ahlukene, njenge-45 degree, 90 degree, 180 degree, okuyiziqu ezivame kakhulu.Futhi kukhona i-60 degree kanye ne-120 degree, kwamanye amapayipi akhethekile.

Ngendololwane engu-90 degree, iphinde ichazwe ngendololwane engu-90d, noma indololwane engu-90 deg.

Iyini i-Elbow Radius

Irediyasi yendololwane isho irediyasi yokugoba.Uma irediyasi ifana nobubanzi bepayipi, ibizwa ngokuthi indololwane yerediyasi emfushane, ebizwa nangokuthi indololwane ye-SR, ngokuvamile ngomfutho ophansi kanye namapayipi anejubane eliphansi.

Uma irediyasi inkulu kunobubanzi bepayipi, R ≥ 1.5 Diameter, khona-ke siyibiza ngokuthi indololwane ye-radius ende (LR Elbow), esetshenziselwa ukucindezela okuphezulu namapayipi okugeleza okuphezulu.

Uma irediyasi ingaphezu kuka-1.5D, njalo ibizwa ngokuthi ukugoba.ukufakwa kwepayipi lokugoba indololwane.Okufana nendololwane engu-2d, ukugoba okungu-2, indololwane engu-3d, ukugoba okungu-3d, njll.

Ukuhlukaniswa ngokwezinto ezibonakalayo

Insimbi ye-Carbon, ebizwa nangokuthi insimbi emnene noma insimbi emnyama.Njenge-ASTM A234 WPB

Uma ufuna izindololwane zensimbi engagqwali, sicela uchofoze lesi sixhumanisi ukuze uthole imininingwane eyengeziwe:IZIndololwane Zensimbi Engagqwali

Uhlobo Lomumo

Kungaba indololwane elinganayo noma Ukunciphisa indololwane

UBUSE BENDLOVU

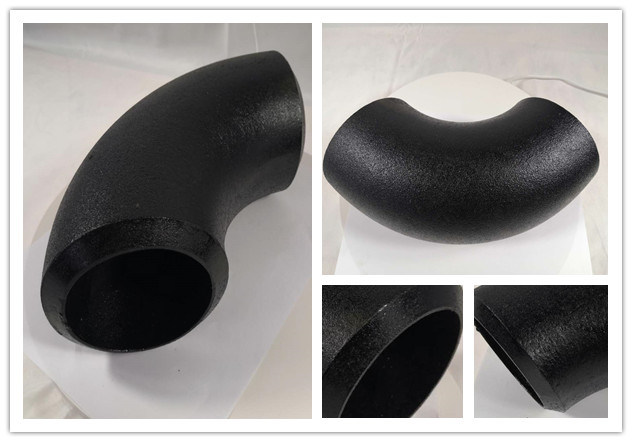

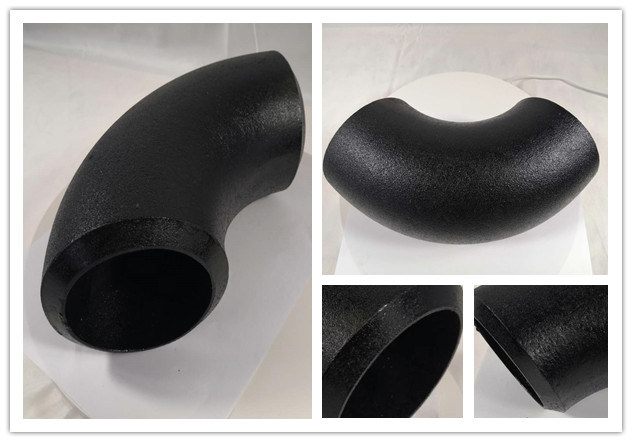

I-Sand Blast

Ngemuva kokwakhiwa okushisayo, sihlela ukuqhuma kwesihlabathi ukuze senze ubuso buhlanzeke futhi bushelelezi.

Ngemva kokuqhuma kwesihlabathi, ukuze kugwenywe ukugqwala, kufanele kwenziwe umdwebo omnyama noma uwoyela ovimbela ukugqwala, i-Hot dip galvanized (HDG) , i-epoxy, i-3PE, indawo enyamalele, njll. Lokho kuncike esicelweni sekhasimende.

UKWELASHWA OKUSHISA

1. Gcina isampula lempahla eluhlaza ukuze uyilandele.

2. Hlela ukwelashwa kokushisa ngokwendinganiso ngokuqinile.

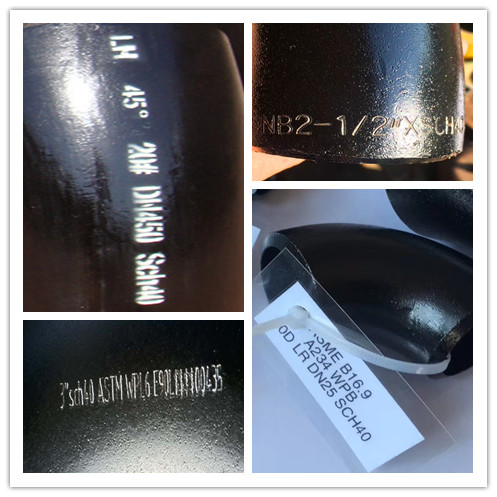

UKUMAKA

Umsebenzi wokumaka ohlukahlukene, ungagoba, upende, ulebuli.Noma ngesicelo sakho.Siyakwamukela ukumaka I-LOGO yakho.

IZITHOMBE EZINEMINININGWANE

1. Ukuphela kwe-bevel njengokusho kwe-ANSI B16.25.

2. Ukuqhuma kwesihlabathi kuqala, bese kuba umsebenzi ophelele wokupenda.Kungenziwa futhi nge-varnish.

3. Ngaphandle kwe-lamination kanye nemifantu.

4. Ngaphandle kokulungiswa kwe-weld.

UKUHLOLA

1. Izilinganiso zobukhulu, zonke zingaphakathi kokubekezelelana okujwayelekile.

2. Ukubekezelela ukuqina:+/-12.5% , noma ngokwesicelo sakho

3. I-PMI

4. MT, UT, X-ray test

5. Yamukela ukuhlolwa komuntu wesithathu

6. Faka isitifiketi se-MTC, EN10204 3.1/3.2

UKUPAKASHA NOKUTHUMELA

1. Ipakishwe ngekesi le-plywood noma i-plywood pallet ngokwe-ISPM15

2. sizobeka uhlu lokupakisha kuphakheji ngayinye

3. sizofaka izimpawu zokuthumela kuphakheji ngayinye.Amagama omaka asesicelweni sakho.

4. Zonke izinto zephakeji lezinkuni azifuzi mahhala

Ukwelashwa kokushisa

1. Gcina isampula lempahla eluhlaza ukuze uyilandele.

2. Hlela ukwelashwa kokushisa ngokwendinganiso ngokuqinile.

Ukumaka

Umsebenzi wokumaka ohlukahlukene, ungagoba, upende, ulebuli.Noma ngesicelo sakho.Siyakwamukela ukumaka I-LOGO yakho.

Izithombe ezinemininingwane

1. Ukuphela kwe-bevel njengokusho kwe-ANSI B16.25.

2. Ukuqhuma kwesihlabathi kuqala, bese kuba umsebenzi ophelele wokupenda.Kungenziwa futhi nge-varnish.

3. Ngaphandle kwe-lamination kanye nemifantu.

4. Ngaphandle kokulungiswa kwe-weld.

Ukuhlola

1. Izilinganiso zobukhulu, zonke zingaphakathi kokubekezelelana okujwayelekile.

2. Ukubekezelela ukuqina:+/-12.5% , noma ngokwesicelo sakho

3. I-PMI

4. MT, UT, X-ray test

5. Yamukela ukuhlolwa komuntu wesithathu

6. Faka isitifiketi se-MTC, EN10204 3.1/3.2

Ukupakisha Nokuthumela

1. Ipakishwe ngekesi le-plywood noma i-plywood pallet ngokwe-ISPM15

2. sizobeka uhlu lokupakisha kuphakheji ngayinye

3. sizofaka izimpawu zokuthumela kuphakheji ngayinye.Amagama omaka asesicelweni sakho.

4. Zonke izinto zephakeji lezinkuni azifuzi mahhala

-

DN50 50A STD 90 degree indololwane ipayipi ifaneleka eside ...

-

carbon steel concentric reducer astm a105 Black...

-

8 Intshi yensimbi engagqwali ipayipi cap ipayipi end cap he...

-

carbon steel sch80 butt esishiselwe ekupheleni 12 intshi sch4...

-

carbon steel A105 A234 WPB ANSI B16.49 3d 30 45...

-

I-Stainless Steel A403 WP316 Butt Weld Pipe Fitti...