Ukufakwa kwepayipi lendololwane le-DN25 25A sch160 elingamadigri angu-90

I-Factory DN25 SCH160 90-Degree Elbow iyi-fitting yamapayipi enziwe ngokunemba, enomfutho ophezulu eyenzelwe ukusetshenziswa okubalulekile lapho ukuthembeka nobuqotho besakhiwo kungaxoxiswana ngakho. Yenziwe ngensimbi yekhabhoni ye-ASTM A234 WPB engenamthungo ngokuhambisana ngokugcwele nezindinganiso ze-ASME B16.9, le ngqimba ye-1.5D Long Radius iyisisombululo esifanele sokuhlanganiswa ezinhlelweni zamapayipi anengcindezi ephezulu ye-Schedule 160. Ukwakhiwa kwayo okungenamthungo kuqinisekisa ukugcinwa kwengcindezi okuphezulu, ukumelana nokukhathala okumangalisayo, kanye nokuphepha okuthuthukisiwe uma kuqhathaniswa nokufakwa okuhlanganisiwe, okwenza kube yingxenye ekhethwayo yezinsizakalo ezidingakalayo ku-petrochemical, ukukhiqizwa kwamandla, kanye nengqalasizinda kawoyela negesi.

Le ngqiniba yenzelwe ukwenza kube lula ukushintsha okubushelelezi okuqonde ngqo okuma-degree angu-90 ekugelezeni koketshezi olunomfutho ophezulu, ukunciphisa ukuxokozela kanye nokwehla kwengcindezi ngenxa yerediyasi yayo yokugoba engu-1.5D elungiselelwe kahle. Imininingwane yezinto ze-ASTM A234 WPB iqinisekisa ukushibilika okuhle kakhulu kanye nezakhiwo eziqinile zemishini, okuvumela ukudalwa kwamalunga aqinile, angavuzi, angenawo amanzi aba yingxenye ebalulekile yepayipi. Yakhelwe ukuhlala isikhathi eside nokusebenza okungantengantengi ezindaweni zokusebenza ezinzima, lokhu kufakwa kuyisisekelo sokwakha onjiniyela kanye nabakhi bomhlaba wonke abazinikele ekwakheni amanethiwekhi amapayipi aqinile, aqinile.

AMAPHARAMETHI OMKHIQIZO

| Igama Lomkhiqizo | Ingqiniba yepayipi |

| Usayizi | Ingqiniba engenamthungo engu-1/2"-36" (ingqiniba ye-SMLS), engu-26"-110" ihlanganiswe ngomthungo. Ububanzi obukhulu bangaphandle bungaba ngu-4000mm |

| Okujwayelekile | I-ANSI B16.9, EN10253-2, DIN2605, GOST17375-2001, JIS B2313, MSS SP 75, njll. |

| Ubukhulu bodonga | I-STD, i-XS, i-XXS, i-SCH20, i-SCH30, i-SCH40, i-SCH60, i-SCH80, i-SCH160, i-XXS njll. |

| Idigri | 30° 45° 60° 90° 180°, njll. |

| Irediyasi | Irediyasi ye-LR/endeshi/R=1.5D, Irediyasi ye-SR/endeshi emfushane/R=1D |

| Ukuphela | Isiphetho se-Bevel/BE/buttweld |

| Ubuso | umbala wemvelo, i-varnished, upende omnyama, uwoyela wokulwa nokugqwala njll. |

| Izinto | Insimbi yekhabhoni:I-A234WPB, A420 WPL6 St37,St45, E24, A42CP, 16Mn, Q345, P245GH,P235GH, P265GH, P280GH, P295GH, P355GH njll. |

| Insimbi yepayipi:I-ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65, WPHY70, WPHY80 njll. | |

| Insimbi ye-Cr-Mo alloy:A234 WP11, WP22, WP5, WP9, WP91, 10CrMo9-10, 16Mo3, 12crmov, njll. | |

| Isicelo | Imboni ye-Petrochemical; imboni yezindiza kanye nezindiza; imboni yezemithi, igesi ephumayo; isitshalo samandla; isakhiwo semikhumbi; ukwelashwa kwamanzi, njll. |

| Izinzuzo | isitoko esilungile, isikhathi sokulethwa esisheshayo; sitholakala ngosayizi bonke, senziwe ngokwezifiso; ikhwalithi ephezulu |

IZINTO ZOKWENZA AMAPHAYIPHI

Ukufakwa kwamapayipi ahlanganisiwe ngezinqe kufaka phakathi indololwane yepayipi yensimbi, i-tee yepayipi yensimbi, i-reduer yepayipi yensimbi, i-cap yepayipi yensimbi. Zonke lezo zingxenye zamapayipi okushisela izinqe, singazihlinzeka ndawonye, sinolwazi lokukhiqiza lweminyaka engama-20.

Uma unesithakazelo nakwezinye izinto zokufakelwa, sicela uchofoze ku-LINK elandelwayo ukuze uhlole imininingwane.

I-PIPE TEE ISINCISHISI SAMAPHAYIPHI ISIVALO SEPAYIPHI I-PIPE BEND IZINTO EZIFAKWE NGOKUQINISEKISA

Izinto Zokusebenza Nokukhiqiza:

Le ngqiniba yenziwe ngepayipi elingenamthungo le-ASTM A234 WPB, into eyenziwe ngensimbi yekhabhoni eqoshiwe echazwe ngensizakalo yokushisa okuphakathi, enikeza ibhalansi efanele yamandla nokuqina. Umkhiqizo usebenzisa inqubo yokushisa nokucindezela okushisayo engenamthungo noma yokungenisa. Le ndlela iqinisekisa ukuthi umzimba wengqiniba awunawo umthungo we-weld weld weld, ngaleyo ndlela isuse umugqa ongaba khona wobuthakathaka. Ngemuva kokwakheka, ukufakwa ngakunye kwelashwa ngokushisa okuvamile ukuze kulungiswe isakhiwo sezinhlamvu, kuncishiswe ukucindezeleka kokwakheka, futhi kubuyiselwe izakhiwo zemishini ezifanele zento.

Ukulawula Okulinganiselwe Kokulinganisa:

Kwenziwe ngokunamathela ngokuqinile ezilinganisweni zobukhulu be-ASME B16.9.

- Ububanzi Bangaphandle: 33.4 mm (± 0.8mm ukubekezelelana).

- Ubukhulu Bodonga: Buhambisana nobukhulu bodonga obuncane be-SCH160 (cishe u-6.55mm). Ukukhiqizwa kuqinisekisa ubukhulu bodonga obufanayo, kanye nokunciphisa izinto ezingeziwe ezilawulwa ngokucophelela ngaphakathi kwemingcele evunyelwe yi-ASME.

- Ubukhulu obuphakathi nokuphela: Kugcinwe kahle ku-38mm (±1.5mm).

- Ukungaguquguquki: Kulawulwa ngokuqinile emaphethelweni epayipi ukuqinisekisa ukuhambisana kahle nokulingana kahle nepayipi lokuhlanganisa.

- I-Weld Bevel: Zombili iziphetho zine-weld bevel engu-37.5° efakwe ngomshini ene-1.6mm (± 0.8mm), enikeza ukulungiselela okuhlanzekile nokuqhubekayo kokushisela okunobunono obuphezulu.

Ubuso Nokumaka:

Izindawo zangaphakathi nezangaphandle zibushelelezi, zikhuthaza indlela yokugeleza engavinjelwe ukunciphisa ukulahleka kwengcindezi. Njengokwejwayelekile, indawo ihlinzekwa ngesikali se-black mill; ukubhula ngesihlabathi okuhlanzekile kwe-Sa2.5 kuyatholakala uma kuceliwe. Ingqiniba ngayinye imakwe unomphela ngokuvumelana ne-ASTM A960, kufaka phakathi: Ibanga Lezinto (A234 WPB), Usayizi (1" SCH160), Ukuhlonza noma Umkhiqizo Womkhiqizi, kanye neNombolo Yokushisa Elandelekayo.

Ukuqinisekiswa Kwezinto Ezingavuthiwe:

Iqoqo ngalinye lepayipi elingenamthungo le-ASTM A234 WPB elisetshenziswa ekukhiqizeni lihambisana nesitifiketi sokuhlolwa kwe-Mill esihambisana ne-ASTM A960. Lapho sithola, senza ukuhlaziywa kwe-spectrochemical ukuqinisekisa ukuhambisana nezidingo zokwakheka kwamakhemikhali ezijwayelekile zezinto ezifana ne-Carbon, i-Manganese, i-Silicon, i-Phosphorus, ne-Sulfur. Amasampula avela endaweni efanayo yokushisa ahlolwa ngempahla yomshini ukuqinisekisa amandla okudonsa, amandla okudonsa, kanye nobude obuhlangabezana nemininingwane ye-A234 WPB (isb., amandla okudonsa amancane angu-415 MPa, amandla okudonsa amancane angu-240 MPa).

Ukuhlolwa Kobukhulu Nokwejiyometri:

Ingqiniba ngayinye eqediwe ihlolwa ngosayizi ongu-100%.

- Ama-Digital Calipers kanye nama-Ultrasonic Thickness Gauges asetshenziselwa ukukala ngokunembile ububanzi bangaphandle kanye nobukhulu bodonga ezindaweni eziningi, ikakhulukazi ukunaka ama-extrados (ukugoba kwangaphandle) lapho kungase kwenzeke khona ukuncipha.

- Ama-Protractors nama-Center-to-End Gauges aqinisekisa i-angle yokugoba engama-degree angu-90 kanye nebanga eliphakathi neliphakathi.

- Ama-gauge angaphandle kokujikeleza ahlola ukugoba kwe-port.

- Ama-Weld Bevel Gauges aqinisekisa ukuthi i-engeli ye-bevel kanye nobukhulu bomhlaba kuhambisana nemininingwane yokushisela.

Ukuhlolwa Komphezulu Nokungabhubhisi (NDT):

- Ukuhlolwa Okubonakalayo: Ukuhlolwa okujulile kwezindawo zangaphakathi nezangaphandle ukuze kutholakale amaphutha anjengokuqhekeka, imithungo, noma ama-lamination.

- Ukuhlolwa Kwezinhlayiya Ze-Magnetic (MT) noma Ukuhlolwa Kokungena Koketshezi (PT): Lonke uhlangothi lwangaphandle, okuhlanganisa neziphetho ezigobile, luhlolwa kusetshenziswa lezi zindlela ukuthola amaphutha aphezulu naseduze kobuso. Lokhu kuhlolwa kwenziwa ngabasebenzi abaqinisekiswe yi-ASNT SNT-TC-1A Level II.

- Ukuskena Kokujiya Kwe-Ultrasonic (UT): Ukuskena okugxilile kwenziwa ezindaweni ezingaphandle nakwezinye izindawo ezingaba khona zokunciphisa ukuze kuqinisekiswe ukuthi ukujiya kodonga kuyahlangabezana noma kudlula ubuncane bomklamo.

Ukulawulwa Kwenqubo Nokuqinisekiswa:

- Ukuqapha Ukwelashwa Kokushisa: Izinga lokushisa kanye nezikhathi zokwelashwa kokushisa okuvamile ziqoshwa ngokuzenzakalelayo futhi zigcinwe, okuqinisekisa ukuhambisana kwenqubo kanye nokulandelela.

- Ukuhlolwa Kwamanzi (Ongakukhetha): Uma iklayenti licela, izindololwane ngazinye zingahlolwa ngokucindezela kwe-hydrostatic, ngokuvamile ngokuphindwe ka-1.5 kunesilinganiso sokucindezela sokushisa esifanele, ukuqinisekisa ubuqotho obuqukethe ingcindezi kanye nokuqina kokuvuza.

Ukuhlolwa Kokugcina kanye Nemibhalo:

Yonke idatha yokuhlola iqoshwa kuHlelo Lokuhlola Nokuhlola (i-ITP). Imikhiqizo edlula kuzo zonke izivivinyo ithola isitifiketi sokukhishwa kokuhlolwa kokugcina. Iphakheji ephelele yamadokhumenti etholakalayo ifaka: isitifiketi sokuhlolwa kwe-Mill (MTC 3.1), umbiko wokuhlolwa kobukhulu, imibiko yokuhlolwa okungonakalisi (uma kusebenza), amarekhodi okwelashwa kokushisa, kanye nemibiko yokuhlolwa yomuntu wesithathu (uma iceliwe yiklayenti).

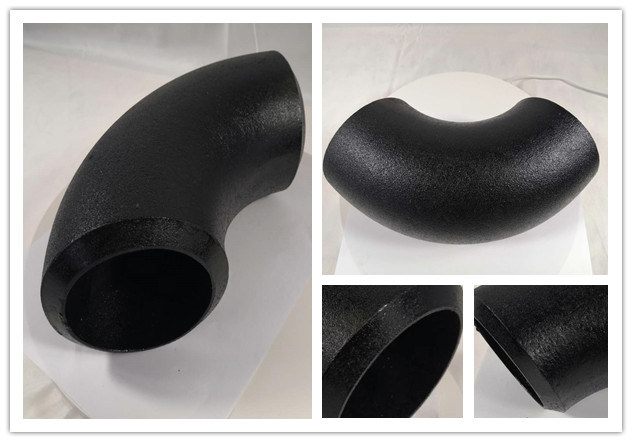

UBUSO BE-ELBOW

Ukuqhuma Kwesihlabathi

Ngemva kokwakheka okushisayo, sihlela ukuqhuma kwesihlabathi ukuze senze indawo ihlanzeke futhi ibushelelezi.

Ngemva kokuqhuma kweSand, ukuze kugwenywe ukugqwala, kufanele upende omnyama noma uwoyela wokulwa nokugqwala, i-Hot dip galvanized (HDG), i-epoxy, i-3PE, indawo enyamalele, njll. Lokho kuncike esicelweni sekhasimende.

UKWELASHWA NGOKUSHISA

1. Gcina isampula yezinto zokusetshenziswa ukuze ulandelele.

2. Hlela ukwelashwa kokushisa ngokwezinga elijwayelekile.

UKUPHAWULA

Imisebenzi ehlukahlukene yokumaka, ingagoba, ipendwe, ibhalwe phansi. Noma ngesicelo sakho. Siyakwamukela ukumaka i-LOGO yakho.

IZITHOMBE EZINEMINININGWANE

1. Isiphetho se-Bevel ngokwe-ANSI B16.25.

2. Ukuqhuma kwesihlabathi kuqala, bese kuba umsebenzi omuhle wokupenda. Kungafakwa i-varnish.

3. Ngaphandle kwe-lamination kanye nemifantu.

4. Ngaphandle kokulungiswa kokushisela.

UKUHLOLA

1. Ukulinganiswa kobukhulu, konke kungaphakathi kokubekezelelana okujwayelekile.

2. Ukubekezelelana kobukhulu: +/- 12.5%, noma ngesicelo sakho

3. I-PMI

4. Ukuhlolwa kwe-MT, UT, i-X-ray

5. Yamukela ukuhlolwa komuntu wesithathu

6. Nikeza isitifiketi se-MTC, EN10204 3.1/3.2

UKUPHAKISHA NOKUTHUMELA

Uma sekuvunyelwe okokugcina, indololwane ngayinye ye-DN25 SCH160 igcotshwa ngokushesha ngamafutha alwa nokugqwala emaphethelweni aqoshiwe nasezindaweni ezifakwe umshini. Bese ivalwa ngayinye esikhwameni sepulasitiki se-Vapor Corrosion Inhibitor (VCI), okuhlinzeka ngokuvikelwa okuqinile ekugqwaleni ngesikhathi sokuthutha nokugcina. Kuma-oda amaningi, izindololwane ezipakishwe ngazinye zihlelwe kahle emabhokisini ezinkuni aqinile athunyelwa kwamanye amazwe noma emabhokisini aqinisiwe, anezihlukanisi ze-foam noma zekhadibhodi zangaphakathi ukuvimbela umonakalo wokuthintana. Amabhokisi aqiniswa ngaphandle ngezintambo zensimbi futhi aphawulwe ngokucacile ngezimpawu zokuphatha ezifana nokuthi "Fragile" kanye nokuthi "Gcina Komile."

Izicelo Zezimboni Ezihlukahlukene:

Le ngqiniba enomfutho ophezulu, enodonga olusindayo iyisinqumo esifanele sezinhlelo zokusebenza ezibalulekile kuzo zonke izimboni ezibalulekile:

- Uwoyela negesi: Imigqa yokucindezela okuphezulu ezindaweni zokuhlanganisa izisekelo zemithombo yamanzi, ama-metering skid, amapayipi esiteshi se-compressor, kanye namayunithi okucubungula amanzi anokucindezela okuphezulu ezindaweni zokuhluza.

- Ukukhiqizwa Kwamandla: Imigqa yamanzi okuhambisa enomfutho ophezulu, izinhlelo eziyinhloko zokudlula umusi, kanye nokuxhumeka kwama-heater anomfutho ophezulu ezitshalweni zamandla.

- Amakhemikhali kanye ne-Petrochemical: Imigqa yokondla nokukhipha ama-reactor anomfutho ophezulu, ukuxhumeka kwama-heat exchanger anomfutho ophezulu, kanye namapayipi ezinqubweni zokwenziwa komfutho ophezulu (isb., i-urea).

- Imishini Yezimboni: Amapayipi okungena nawokuphuma kwamaphampu anomfutho ophezulu, imigqa yesistimu ye-hydraulic, kanye nezinhlelo zokusebenza ezingaphansi kokujikeleza okukhulu komfutho noma ukushaya.

Izinzuzo Zethu Zokuncintisana:

- Ubuchwepheshe ku-High-Pressure Fittings: Sinobuchwepheshe obukhethekile ekukhiqizeni i-SCH160 kanye ne-fittings zezinga eliphezulu, ngokukhethwa kwezinto kanye nokulawulwa kwenqubo okulungiselelwe ngokukhethekile isevisi ye-high-pressure.

- Isiqinisekiso Sobuqotho Esingenamthungo: Ukuzibophezela kwethu kubuchwepheshe bokukhiqiza obungenamthungo kususa izingozi ezihlobene nemithungo yokushisela, okuletha izinga eliphezulu lokuphepha nokuthembeka kumakhasimende ethu.

- Ukuphathwa Kwekhwalithi Okuqinile: Iphrothokholi yokuhlola enezigaba eziningi, enokuhlolwa okuqinile esinyathelweni ngasinye sokukhiqiza—ikakhulukazi i-NDT ebalulekile yezingxenye ezinengcindezi ephezulu—iqinisekisa ifilosofi engenasici yemikhiqizo ephumayo.

Ukufakwa kwamapayipi kuyizinto ezibalulekile ohlelweni lwamapayipi, ezisetshenziselwa ukuxhuma, ukuqondisa kabusha, ukuphambukisa, ukushintsha usayizi, ukuvala noma ukulawula ukugeleza koketshezi. Zisetshenziswa kabanzi emikhakheni efana nokwakha, imboni, amandla kanye nezinsizakalo zikamasipala.

Imisebenzi Eyinhloko:Ingenza imisebenzi efana nokuxhuma amapayipi, ukushintsha indlela yokugeleza, ukuhlukanisa nokuhlanganisa ukugeleza, ukulungisa ububanzi bamapayipi, ukuvala amapayipi, ukulawula nokulawula.

Ububanzi Bokusetshenziswa:

- Ukwakhiwa kwamanzi kanye nokukhipha amanzi:Izindololwane ze-PVC kanye ne-PPR tris zisetshenziselwa amanethiwekhi amapayipi amanzi.

- Amapayipi ezimboni:Ama-flange ensimbi engagqwali kanye nezindololwane zensimbi ezixutshwe ngomlotha zisetshenziselwa ukuthutha izinto zamakhemikhali.

- Ukuthuthwa kwamandla:Izithako zamapayipi ensimbi anomfutho ophezulu zisetshenziswa emapayipini kawoyela negesi.

- I-HVAC (Ukushisa, Umoya Ongenisayo, kanye Nomoya Ongenisayo):Izithako zamapayipi ethusi zisetshenziselwa ukuxhuma amapayipi efriji, kanti amalunga aguquguqukayo asetshenziselwa ukunciphisa ukudlidliza.

- Ukunisela ngenkasa kwezolimo:Izixhumi ezisheshayo zenza kube lula ukuhlanganiswa nokuhlukaniswa kwezinhlelo zokunisela ezifafaza.

-

I-flange yensimbi engagqwali engenamthungo engu-321ss ...

-

I-ANSI B16.9 Insimbi Yekhabhoni Egobile Ngamadigri angu-45 Ukugoba Kokushisela

-

I-ASTM B 16.9 Pipe Fitting Carbon Steel Butt Weld ...

-

I-ANSI B16.9 insimbi engagqwali engu-45 degree butt weld ...

-

Ukufakwa Kwepayipi Kwensimbi Engagqwali Insimbi Emhlophe Yensimbi Engagqwali ...

-

Insimbi engagqwali engu-45/60/90/180 Degree Elbow