Amavalvu esango zisetshenziselwa ukuvala ukugeleza koketshezi kunokuba kulawulwe ukugeleza. Uma ivuliwe ngokugcwele, ivalvu yesango evamile ayinawo umgoqo endleleni yokugeleza, okuholela ekumelaneni okuphansi kakhulu kokugeleza. Ubukhulu bendlela yokugeleza evulekile ngokuvamile buyahlukahluka ngendlela engeyona eyemigqa njengoba isango lihanjiswa. Lokhu kusho ukuthi izinga lokugeleza alishintshi ngokulinganayo ngokuhamba kwesiqu. Kuye ngokwakhiwa, isango elivulekile kancane lingadlidliza ngenxa yokugeleza koketshezi.

Izici Zokuklama

- Isikulufa Nejoka Langaphandle (OS&Y)

- I-Two Piece self aligning packing gland

- Ibhonethi enebholti ene-gasket eneziphazamiso

- Isihlalo sangemuva esihlanganisiwe

Imininingwane

- Umklamo Oyisisekelo: I-API 602, i-ANSI B16.34

- Kusukela Ekupheleni: I-DHV Standard

- Ukuhlolwa Nokuhlolwa: API-598

- Iziphetho Ezinezikulufo (NPT) zibe yi-ANSI/ASME B1.20.1

- Ukuphela kokushintshwa kwesokhethi kuya ku-ASME B16.11

- Ukushintshwa kwe-Butt Ends kuya ku-ASME B16.25

- I-Flange Yokuphela: ANSI B16.5

Izici Ongakukhetha

- Insimbi Ebunjiwe, Insimbi Ehlanganisiwe, Insimbi Engagqwali

- Imbobo Egcwele noma Imbobo Ejwayelekile

- Isiqu Esandisiwe noma Ngaphansi Kophawu

- Ibhonethi Ehlanganisiwe noma Ibhonethi Yokuvala Ukucindezela

- Idivayisi Ekhiywayo uma iceliwe

- Ukukhiqiza ku-NACE MR0175 uma kuceliwe

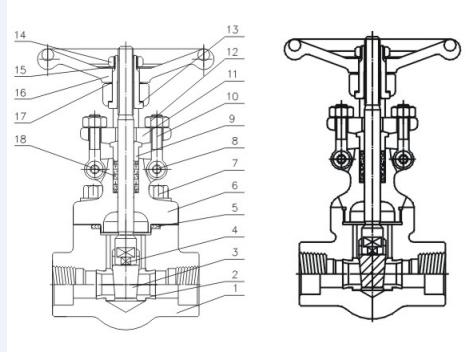

Ukudweba Imikhiqizo

Izindinganiso Zokusebenza

1.Ukuklama nokukhiqiza kuhambisana ne-API 602, BS5352, ANSI B 16.34

2. Ukuxhumana kuphetha ngokusuka ku:

1) Ubukhulu be-socket weld buvumelana ne-ANSI B 16.11, JB/T 1751

2) Ubukhulu beziphetho zesikulufu buvumelana ne-ANSI B 1.20.1, JB/T 7306

3) I-Butt-Welded ivumelane ne-ANSI B16.25, JB/T12224

4) Iziphetho ezigobile zihambisana ne-ANSI B 16.5, JB79

3. Ukuhlolwa nokuhlolwa kuhambisana nalokhu:

1) I-API 598, GB/T 13927, JB/T9092

4. Izici zesakhiwo:

Ibhonethi enebholti, isikulufu sangaphandle kanye nejoka

Ibhonethi ehlanganisiwe, izikrini zangaphandle kanye nejoka

5. Izinto zokwakha zivumelana ne-ANSI/ASTM

6. Izinto Eziyinhloko:

I-A105,LF2,F5,F11,F22,304(L),316(L),F347,F321,F51,Monel,20Alloy

Insimbi yekhabhoni Izinga lokushisa-Ingcindezi

CL150-285 PSI@ 100°F

CL300-740 PSI@ 100°F

CL600-1480 PSI@ 100°F

CL800-1975 PSI@ 100°F

CL1500-3705 PSI@ 100°F

Uhlu Lwezinto Eziyinhloko Eziyingxenye

| NO | Igama Lengxenye | A105/F6a | I-A105/F6a HFS | LF2/304 | F11/F6AHF | F304(L) | F316(L) | F51 |

| 1 | Umzimba | A105 | A105 | I-LF2 | F11 | F304(L) | F316(L) | F51 |

| 2 | Isihlalo | 410 | 410HF | 304 | 410HF | 304(L) | 316(L) | F51 |

| 3 | I-Wedge | F6a | F6a | F304 | F6aHF | F304(L) | F306(L) | F51 |

| 4 | Isiqu | 410 | 410 | 304 | 410 | 304(L) | 316(L) | F51 |

| 5 | I-Gasket | I-Graphite Eguquguqukayo engu-304+ | I-Graphite Eguquguqukayo engu-304+ | I-Graphite Eguquguqukayo engu-304+ | I-Graphite Eguquguqukayo engu-304+ | I-Graphite Eguquguqukayo engu-304+ | I-Graphite Eguquguqukayo engu-316+ | I-Graphite Eguquguqukayo engu-316+ |

| 6 | Ibhonethi | A105 | A105 | I-LF2 | F11 | F304(L) | F316(L) | F51 |

| 7 | I-Bolt | B7 | b7 | L7 | B16 | B8(M) | B8(M) | B8(M) |

| 8 | Iphinikhodi | 410 | 410 | 410 | 410 | 304 | 304 | 304 |

| 9 | Indlala | 410 | 410 | 304 | 410 | 304 | 316 | F51 |

| 10 | I-Gland eyebolt | B7 | B7 | L7 | B16 | B8M | B8M | B8M |

| 11 | I-Gland Flange | A105 | A105 | I-LF2 | F11 | F304 | F304 | F304 |

| 12 | I-Hex nut | 2H | 2H | 2H | 2H | 8M | 8M | 8M |

| 13 | I-stem nut | 410 | 410 | 410 | 410 | 410 | 410 | 410 |

| 14 | I-Locking nut | 35 | 35 | 35 | 35 | 35 | 35 | 35 |

| 15 | Ipuleti legama | AL | AL | AL | AL | AL | AL | AL |

| 16 | Isondo lesandla | A197 | A197 | A197 | A197 | A197 | A197 | A197 |

| 17 | I-Gasket Yokugcoba | 410 | 410 | 410 | 410 | 410 | 410 | 410 |

| 18 | Ukupakisha | I-Graphite | I-Graphite | I-Graphite | I-Graphite | I-Graphite | I-Graphite | I-Graphite |

Ukufakwa kwamapayipi kuyizinto ezibalulekile ohlelweni lwamapayipi, ezisetshenziselwa ukuxhuma, ukuqondisa kabusha, ukuphambukisa, ukushintsha usayizi, ukuvala noma ukulawula ukugeleza koketshezi. Zisetshenziswa kabanzi emikhakheni efana nokwakha, imboni, amandla kanye nezinsizakalo zikamasipala.

Imisebenzi Eyinhloko:Ingenza imisebenzi efana nokuxhuma amapayipi, ukushintsha indlela yokugeleza, ukuhlukanisa nokuhlanganisa ukugeleza, ukulungisa ububanzi bamapayipi, ukuvala amapayipi, ukulawula nokulawula.

Ububanzi Bokusetshenziswa:

- Ukwakhiwa kwamanzi kanye nokukhipha amanzi:Izindololwane ze-PVC kanye ne-PPR tris zisetshenziselwa amanethiwekhi amapayipi amanzi.

- Amapayipi ezimboni:Ama-flange ensimbi engagqwali kanye nezindololwane zensimbi ezixutshwe ngomlotha zisetshenziselwa ukuthutha izinto zamakhemikhali.

- Ukuthuthwa kwamandla:Izithako zamapayipi ensimbi anomfutho ophezulu zisetshenziswa emapayipini kawoyela negesi.

- I-HVAC (Ukushisa, Umoya Ongenisayo, kanye Nomoya Ongenisayo):Izithako zamapayipi ethusi zisetshenziselwa ukuxhuma amapayipi efriji, kanti amalunga aguquguqukayo asetshenziselwa ukunciphisa ukudlidliza.

- Ukunisela ngenkasa kwezolimo:Izixhumi ezisheshayo zenza kube lula ukuhlanganiswa nokuhlukaniswa kwezinhlelo zokunisela ezifafaza.