Amathiphu

I-Needle Valve esezingeni eliphezulu ingasebenza ngesandla noma ngokuzenzakalelayo. Ama-valve enaliti asetshenziswa ngesandla asebenzisa i-handwheel ukulawula ibanga eliphakathi kwe-plunger nesihlalo se-valve. Uma i-handwheel ijikeleziswa ohlangothini olulodwa, i-plunger iyaphakanyiswa ukuvula i-valve futhi ivumele uketshezi ludlule. Uma i-handwheel ijikeleziswa kolunye uhlangothi, i-plunger isondela esihlalweni ukuze yehlise izinga lokugeleza noma ivale i-valve.

Amavalvu enaliti azenzakalelayo axhunywe kumotha we-hydraulic noma i-actuator yomoya evula futhi ivale ngokuzenzakalelayo ivalvu. Imotha noma i-actuator izolungisa indawo ye-plunger ngokuya ngama-timer noma idatha yokusebenza yangaphandle eqoqwe lapho kubhekwa imishini.

Amavalvu enaliti asebenza ngesandla kanye nasebenza ngokuzenzakalelayo anikeza ukulawula okunembile kwesilinganiso sokugeleza. Isondo lesandla lifakwe kahle, okusho ukuthi kuthatha ukujika okuningana ukulungisa indawo ye-plunger. Ngenxa yalokho, ivalvu yenaliti ingakusiza ukuthi ulawule kangcono izinga lokugeleza koketshezi ohlelweni.

Izici Zevalvu Yenaliti Izinto Nezithombe

1. Ivalvu yenaliti

2. Yenziwe ngensimbi engagqwali i-ASTM A479-04 (Ibanga 316)

3. Iziphetho ezinentambo ngokusho kwe-ASME B 1.20.1(NPT)

4. Ukucindezela Okuphezulu Kokusebenza 6000 psi ku-38 °C

5. Izinga Lokushisa Elisebenzayo -54 kuya ku-232°C

6. Ukhiye webhonethi yokuphepha uvimbela ukulahlekelwa ngengozi.

7. Umklamo wezihlalo zangemuva uvikela ukupakisha endaweni evulekile ngokuphelele.

| Inombolo | Igama | Izinto | Ukwelashwa Okuphezulu |

| 1 | Isibambo Sezikrini Zegrib | SS316 | |

| 2 | Isibambo | SS316 | |

| 3 | Umgodi Wesiqu | SS316 | Ukwelashwa kwe-nitrogen |

| 4 | Isivalo Sothuli | Ipulasitiki | |

| 5 | I-nut yokupakisha | SS316 | |

| 6 | I-Lock Nut | SS316 | |

| 7 | Ibhonethi | SS316 | |

| 8 | Umshini wokuwasha | SS316 | |

| 9 | Ukupakisha Isiqu | I-PTFE+Graphite | |

| 10 | I-Wahser | SS316 | |

| 11 | Iphinikhodi yokukhiya | SS316 | |

| 12 | Indandatho ye-O | I-FKM | |

| 13 | Umzimba | Ibanga 316 |

I-Needle Valve Dimension Generals

| Ireferensi | Usayizi | I-PN(psi) | E | H | L | M | K | ISISINDO(Kg) |

| 225N 02 | 1/4" | 6000 | 25.5 | 90 | 61 | 55 | 4 | 0.365 |

| 225N 03 | 3/8" | 6000 | 25.5 | 90 | 61 | 55 | 4 | 0.355 |

| 225N 04 | 1/2" | 6000 | 28.5 | 92 | 68 | 55 | 5 | 0.440 |

| 225N 05 | 3/4" | 6000 | 38 | 98 | 76 | 55 | 6 | 0.800 |

| 225N 06 | 1" | 6000 | 44.5 | 108 | 85 | 55 | 8 | 1.120 |

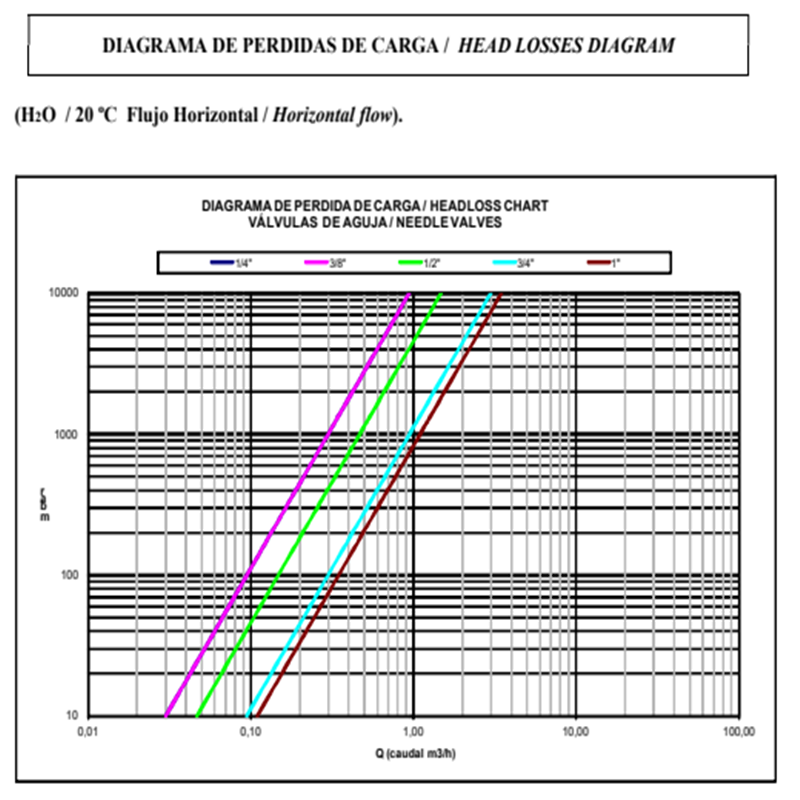

Umdwebo Wokulahlekelwa Kwekhanda Le-Needle Valve

Isilinganiso Sokushisa Kwengcindezi Yamavalvu Enaliti

AMANANI E-Kv

I-KV = Izinga lokugeleza kwamanzi ku-cubic meter ngehora (m³/h) elizokhiqiza ukwehla kwengcindezi kwebha eli-1 kulo lonke ivalvu.

| usayizi | 1/4" | 3/8" | 1/2" | 3/4" | 1" |

| m³/h | 0.3 | 0.3 | 0.63 | 0.73 | 1.4 |

Ukufakwa kwamapayipi kuyizinto ezibalulekile ohlelweni lwamapayipi, ezisetshenziselwa ukuxhuma, ukuqondisa kabusha, ukuphambukisa, ukushintsha usayizi, ukuvala noma ukulawula ukugeleza koketshezi. Zisetshenziswa kabanzi emikhakheni efana nokwakha, imboni, amandla kanye nezinsizakalo zikamasipala.

Imisebenzi Eyinhloko:Ingenza imisebenzi efana nokuxhuma amapayipi, ukushintsha indlela yokugeleza, ukuhlukanisa nokuhlanganisa ukugeleza, ukulungisa ububanzi bamapayipi, ukuvala amapayipi, ukulawula nokulawula.

Ububanzi Bokusetshenziswa:

- Ukwakhiwa kwamanzi kanye nokukhipha amanzi:Izindololwane ze-PVC kanye ne-PPR tris zisetshenziselwa amanethiwekhi amapayipi amanzi.

- Amapayipi ezimboni:Ama-flange ensimbi engagqwali kanye nezindololwane zensimbi ezixutshwe ngomlotha zisetshenziselwa ukuthutha izinto zamakhemikhali.

- Ukuthuthwa kwamandla:Izithako zamapayipi ensimbi anomfutho ophezulu zisetshenziswa emapayipini kawoyela negesi.

- I-HVAC (Ukushisa, Umoya Ongenisayo, kanye Nomoya Ongenisayo):Izithako zamapayipi ethusi zisetshenziselwa ukuxhuma amapayipi efriji, kanti amalunga aguquguqukayo asetshenziselwa ukunciphisa ukudlidliza.

- Ukunisela ngenkasa kwezolimo:Izixhumi ezisheshayo zenza kube lula ukuhlanganiswa nokuhlukaniswa kwezinhlelo zokunisela ezifafaza.