INCAZELO YOMKHIQIZO

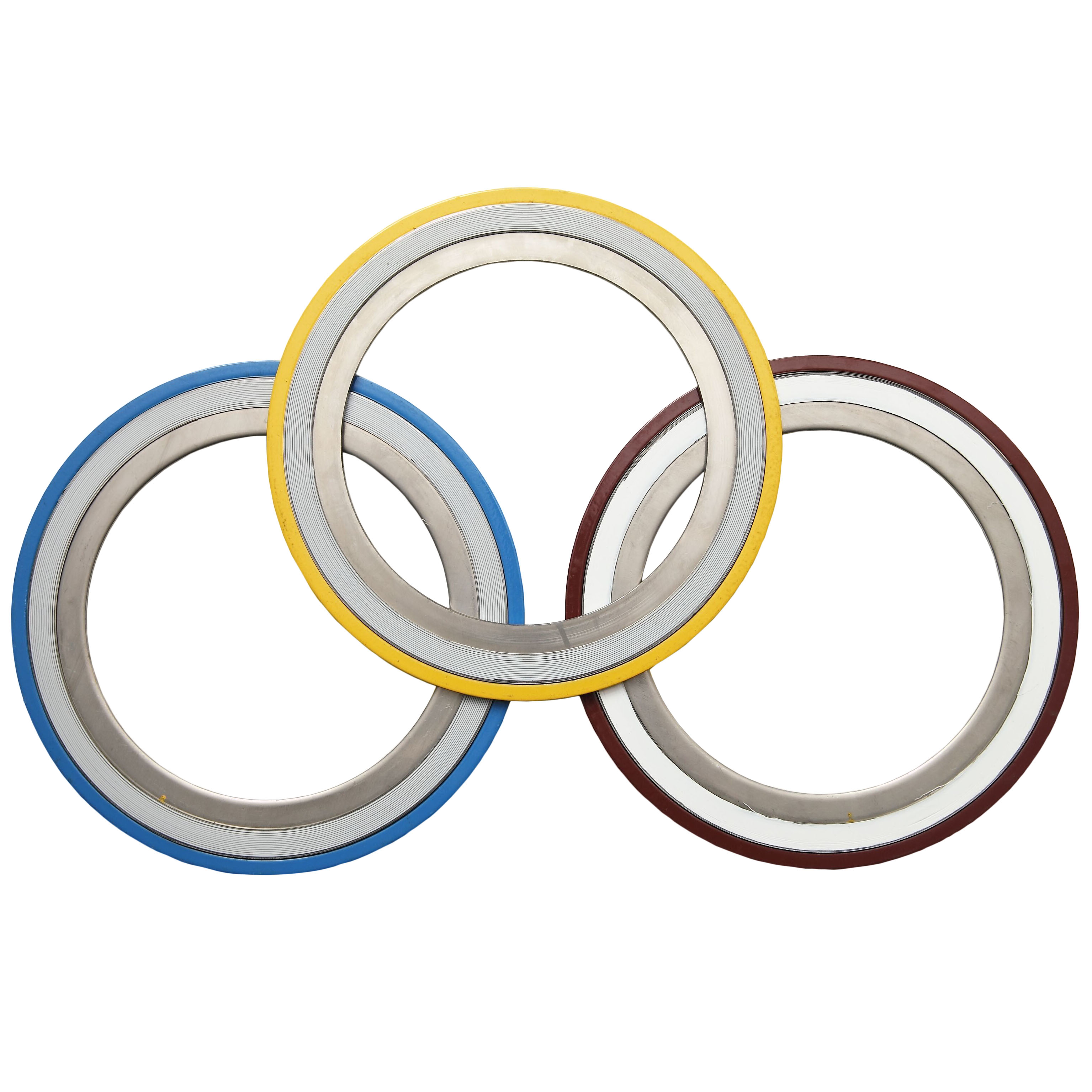

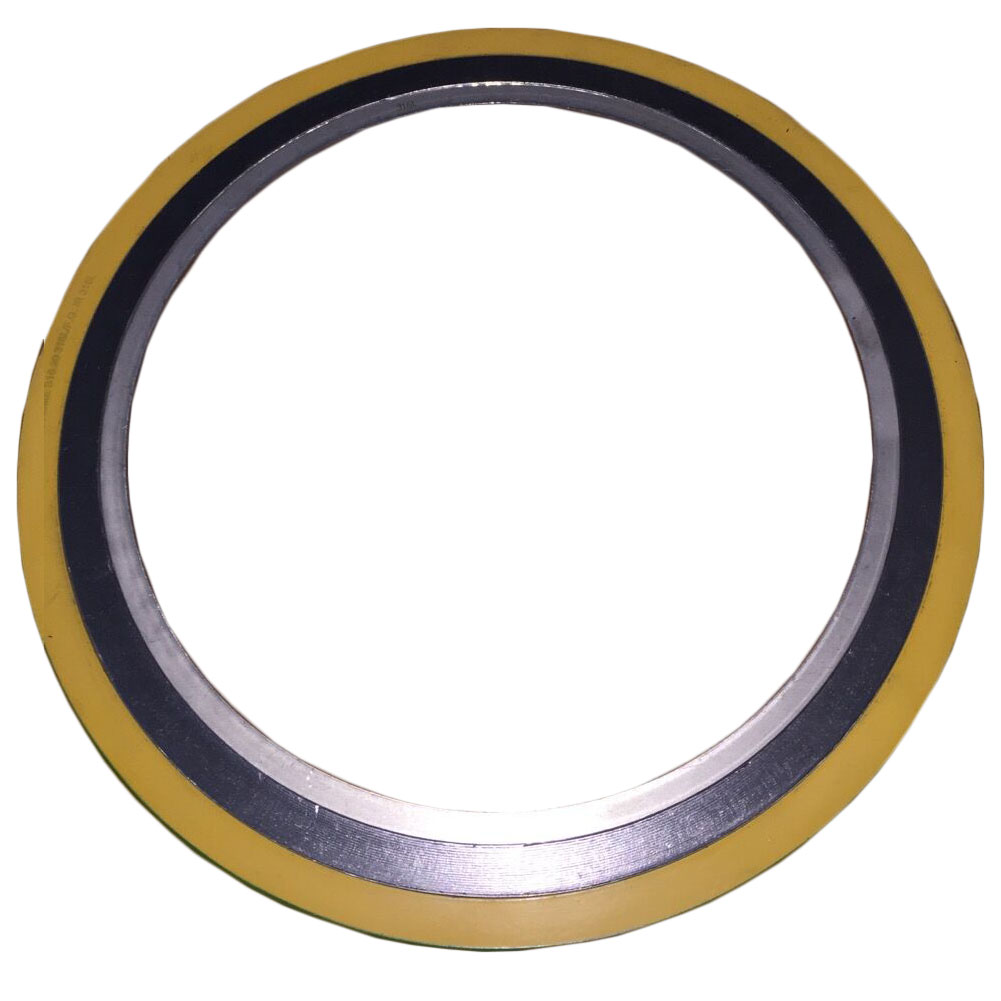

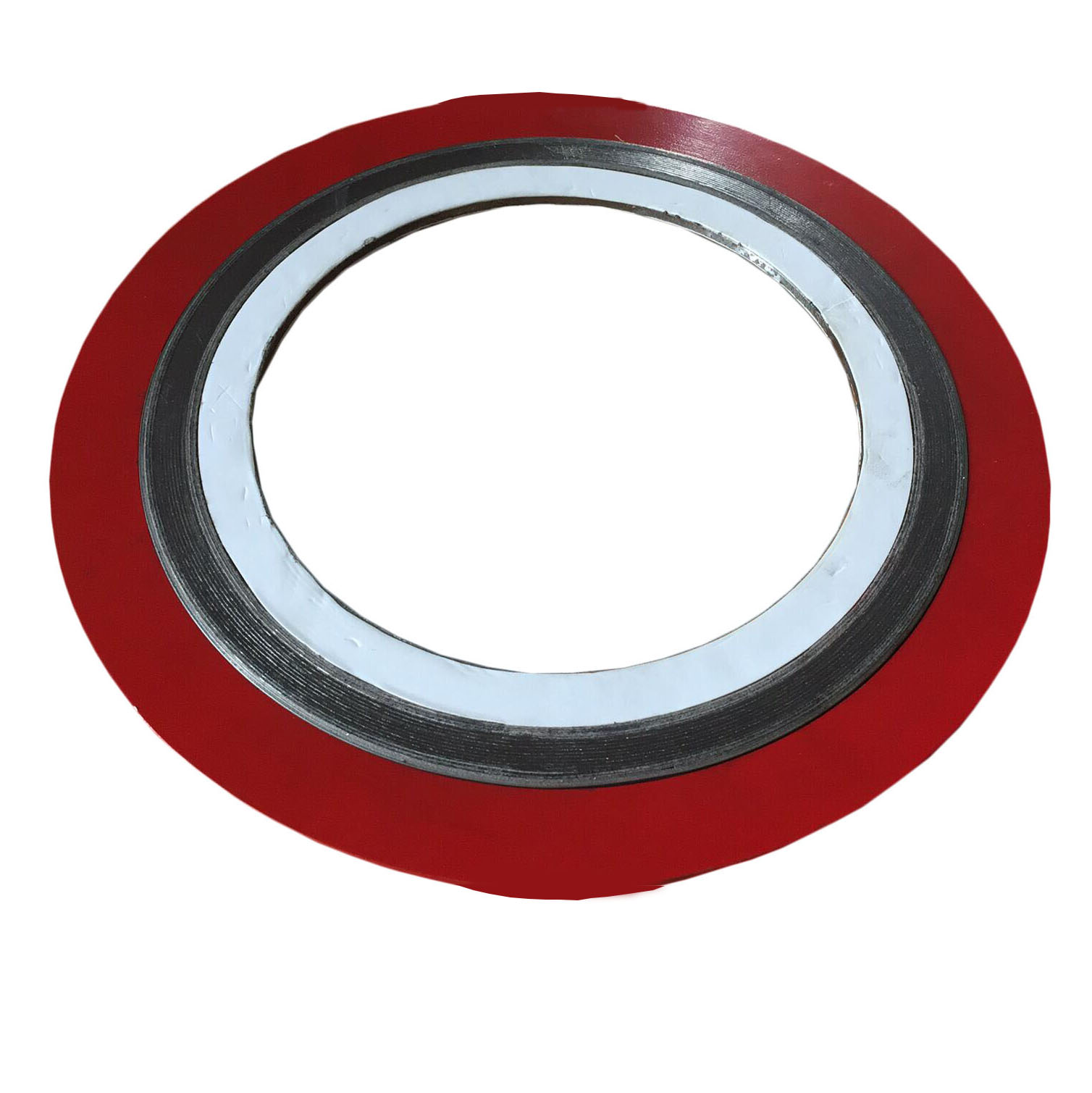

Ama-gasket e-Flange

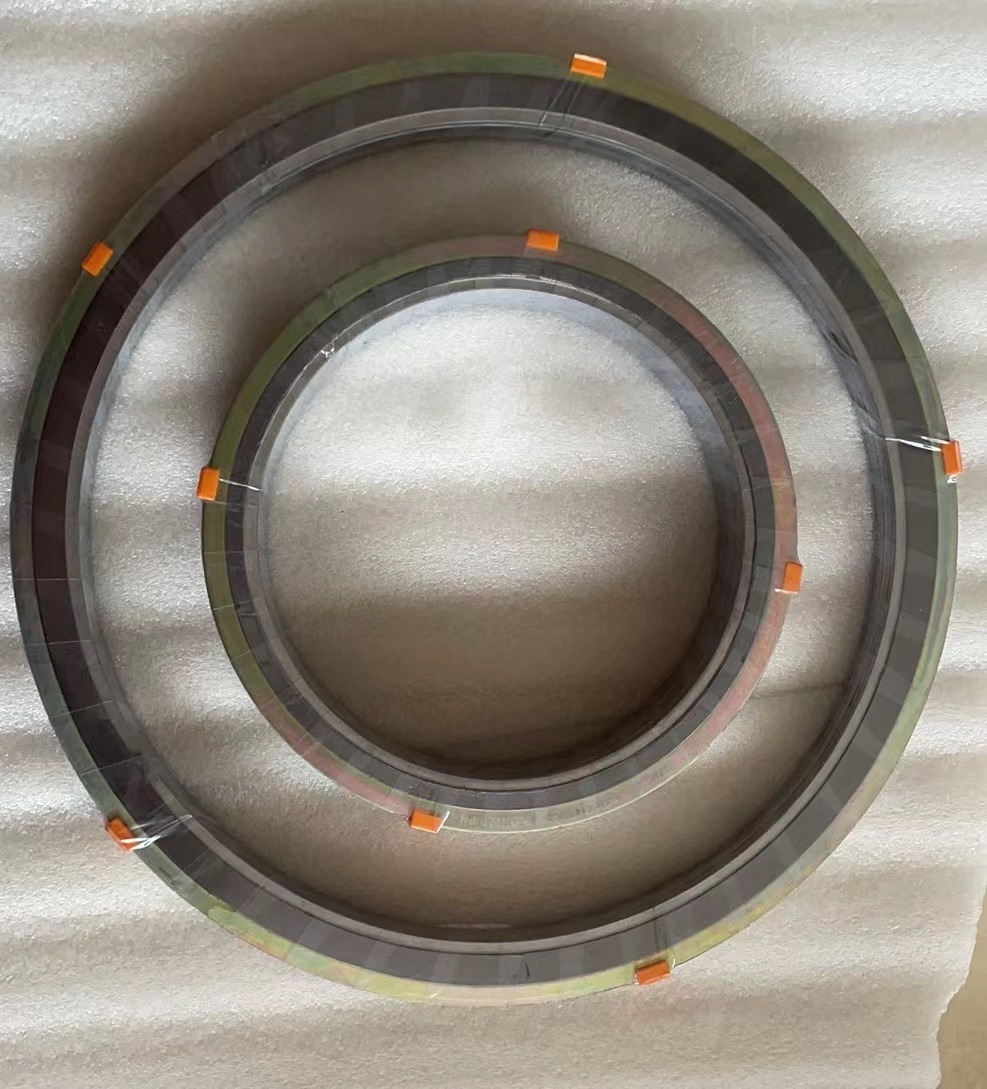

Ama-gasket e-Flange ahlukaniswe ngama-gasket enjoloba, ama-gasket e-graphite, kanye nama-gasket e-metal spiral (uhlobo oluyisisekelo). Asebenzisa ama-standard kanye nama-gasket

Izinto zokwakha zihlanganiswa futhi ziboshwe ngendlela ejikelezayo, futhi ibhande lensimbi liqiniswa ngokushisela amabala ekuqaleni nasekupheleni.

Umsebenzi uwukudlala indima yokuvala phakathi kwama-flange amabili.

Ukusebenza

Ukusebenza: izinga lokushisa eliphezulu, umfutho ophezulu, ukumelana nokugqwala, izinga elihle lokucindezela kanye nezinga lokubuyela emuva.

Izingxenye zamapayipi, amavalvu, amaphampu, ama-manhole, imikhumbi yokucindezela kanye nemishini yokushintshanisa ukushisa ezindaweni zokuhlangana kwephethiloli, amakhemikhali, amandla kagesi, i-metallurgy, ukwakha imikhumbi, ukwenza amaphepha, imithi, njll. ziyizinto ezifanelekile zokuvala ezingashukumi.

kanye nomusi ophakeme, uwoyela, uwoyela negesi, isinyibilikisi, uwoyela womzimba wamalahle ashisayo, njll.

AMAPHARAMETHI OMKHIQIZO

| Izinto Zokugcwalisa | I-Asbestos | I-graphite eguquguqukayo (FG) | I-Polytetrafluoroethylene (PTFE) |

| Ibhande lensimbi | I-SUS 304 | I-SUS 316 | I-SUS 316L |

| Indandatho Yangaphakathi | Insimbi Yekhabhoni | I-SUS 304 | I-SUS 316 |

| Izinto Zokulenga Zangaphandle | Insimbi Yekhabhoni | I-SUS 304 | I-SUS 316 |

| Izinga lokushisa (°C) | -150~450 | -200~550 | 240~260 |

| Ingcindezi yokusebenza ephezulu (kg/cm2) | 100 | 250 | 100 |

IZITHOMBE EZINEMINININGWANE

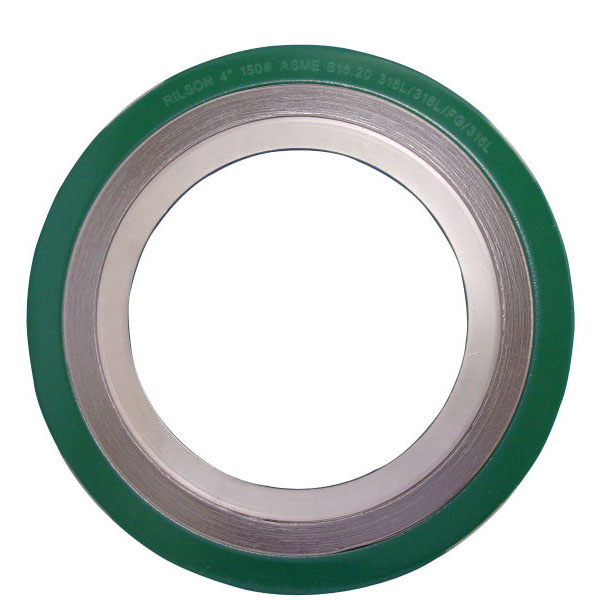

1. I-ASME B16.20 ngokwemidwebo yamakhasimende

2. 150#,300#,600#,900#1500#,2500#,njll

3. Ngaphandle kwe-lamination kanye nemifantu.

4. Nge-flange epayipini noma kwenye

UKUPHAKISHA NOKUTHUMELA

1. Ipakishwe ngebhokisi le-plywood noma i-plywood pallet ngokwe-ISPM15

2. sizobeka uhlu lokupakisha kuphakheji ngayinye

3. sizobeka izimpawu zokuthumela kuphakheji ngayinye. Amagama ezimpawu akhona ngokwesicelo sakho.

4. Zonke izinto zokupakisha izinkuni azinawo uphethiloli

MAYELANA NATHI

Sinesipiliyoni Esisebenzayo Seminyaka Engaphezu Kwengu-20 Esikhungweni Sezokuphatha

Iminyaka engaphezu kwengu-20 yesipiliyoni sokukhiqiza. Imikhiqizo esingayinikeza ngepayipi lensimbi, ukufakwa kwamapayipi e-bw, ukufakwa okuhlanganisiwe, ama-flange ahlanganisiwe, ama-valve ezimboni. Ama-Bolts nama-Nuts, nama-gasket. Izinto zokwakha zingaba yinsimbi yekhabhoni, insimbi engagqwali, insimbi ye-Cr-Mo alloy, i-inconel, i-incoloy alloy, insimbi yekhabhoni enezinga lokushisa eliphansi, njalo njalo. Singathanda ukunikeza iphakheji ephelele yamaphrojekthi akho, ukukusiza wonge izindleko futhi kube lula ukungenisa.

Imibuzo Evame Ukubuzwa

1. Kuyini i-graphite filler yensimbi engagqwali?

I-Stainless Steel Graphite Packing iyinto yokupakisha noma yokuvala esetshenziselwa ukuvimbela ukuvuza kwezicelo ezifaka amazinga okushisa aphezulu kanye nengcindezi. Yakhiwe ngocingo lwensimbi engagqwali olulukiwe kanye ne-graphite efakwe emanzini ukuze ikwazi ukumelana nokushisa okuhle kanye nokuhambisana namakhemikhali.

2. Zisetshenziswa kuphi izithasiselo ze-graphite zensimbi engagqwali?

Ama-graphite filler ensimbi engagqwali avame ukusetshenziswa emikhakheni eyahlukene okuhlanganisa ukucubungula amakhemikhali, i-petrochemical, uwoyela negesi, ukukhiqizwa kwamandla, i-pulp nephepha, nokuningi. Afanele ukusetshenziswa okubandakanya uketshezi olufana nama-asidi, izinyibilikisi, umusi kanye nezinye izinto ezilimazayo.

3. Yiziphi izinzuzo zokugcwalisa i-graphite yensimbi engagqwali?

Ezinye zezinzuzo zokupakisha i-graphite yensimbi engagqwali zifaka phakathi ukumelana nokushisa okuphezulu, ukumelana namakhemikhali okuhle kakhulu, i-coefficient ephansi yokungqubuzana, ukuhanjiswa okuhle kokushisa kanye nezakhiwo zokuvala eziphakeme. Ingaphinde iphathe isivinini se-rpm ephezulu kanye ne-shaft ngaphandle kokuphazamisa ukusebenza kwayo.

4. Ungayifaka kanjani i-graphite yensimbi engagqwali?

Ukuze ufake i-graphite yensimbi engagqwali, susa i-packing endala bese uhlanza ibhokisi lokugxusha kahle. Sika izinto zokupakisha ezintsha zibe ubude obufunayo bese uzifaka ebhokisini lokugxusha ngokwemiyalelo yomenzi. Sebenzisa i-packing gland ukuze ucindezele ngokulinganayo i-packing bese uqinisa i-packing gland ukuze uvimbele ukuvuza.

5. Iyini i-spiral wound gasket?

I-spiral wound gasket iyi-semi-metallic gasket equkethe izendlalelo ezishintshanayo zensimbi nezinto zokugcwalisa (ngokuvamile i-graphite noma i-PTFE). Lawa ma-gasket aklanyelwe ukuhlinzeka ngesisombululo sokuvala esiqinile nesithembekile sokuxhumeka kwe-flange okubhekene nokushisa okuphezulu, ukucindezeleka kanye nemidiya ehlukahlukene.

6. Zisetshenziswa kuphi izigxobo ze-spiral wound?

Ama-gasket e-Spiral wound avame ukusetshenziswa ezimbonini ezifana nokucubungula amakhemikhali, uwoyela negesi, izindawo zokuhluza, ukukhiqizwa kukagesi kanye namapayipi. Afanele ukusetshenziswa okubandakanya umusi, ama-hydrocarbon, ama-acid kanye nolunye uketshezi olubolayo.

7. Yiziphi izinzuzo zama-gasket e-spiral wound?

Ezinye zezinzuzo zama-spiral wound gasket zihlanganisa ukumelana namazinga okushisa aphezulu kanye nokucindezela, ukuguquguquka okuhle kakhulu, amakhono okuvala amahle kakhulu, ukuzivumelanisa nezimo ze-flange, kanye nokuhambisana okuhle kakhulu kwamakhemikhali. Angamelana nokujikeleza kokushisa futhi agcine ubuqotho be-seal.

8. Ungayikhetha kanjani i-spiral wound gasket efanele?

Ukuze ukhethe i-spiral wound gasket efanele, cabangela izici ezifana nokushisa nokusebenza kanye nengcindezi, uhlobo loketshezi, ukuphela kobuso be-flange, usayizi we-flange, kanye nokuba khona kwanoma iyiphi imidiya ebolile. Ukubonisana nomhlinzeki we-gasket noma umenzi kungasiza ekunqumeni i-gasket engcono kakhulu yokusetshenziswa.

9. Ungayifaka kanjani i-spiral wound gasket?

Ukuze ufake i-gasket ye-spiral wound, qiniseka ukuthi ubuso be-flange buhlanzekile futhi abunazo izinsalela noma izinto ezindala ze-gasket. Beka i-washer e-flange phakathi bese uqondanisa imigodi ye-bolt. Faka ingcindezi elinganayo lapho uqinisa ama-bolt ukuqinisekisa ingcindezi elinganayo ku-gasket. Landela ukulandelana kokuqinisa okunconyiwe kanye namanani e-torque anikezwe umenzi we-gasket.

10. Ingabe ama-gasket e-spiral wound angasetshenziswa kabusha?

Nakuba ama-gasket e-spiral wound angasetshenziswa kabusha kwezinye izimo, ngokuvamile kunconywa ukuthi uwashintshe ngama-gasket amasha ukuqinisekisa ukusebenza kahle kokuvala. Ukusebenzisa kabusha ama-gasket kungabangela ukwehla kokusebenza, ukulahlekelwa ukucindezelwa, kanye nokuvuza okungenzeka. Imikhuba yokuhlola nokulungisa njalo kufanele ilandelwe ukuze kutholakale ngokushesha futhi kufakwe ama-gasket agugile.

Ukufakwa kwamapayipi kuyizinto ezibalulekile ohlelweni lwamapayipi, ezisetshenziselwa ukuxhuma, ukuqondisa kabusha, ukuphambukisa, ukushintsha usayizi, ukuvala noma ukulawula ukugeleza koketshezi. Zisetshenziswa kabanzi emikhakheni efana nokwakha, imboni, amandla kanye nezinsizakalo zikamasipala.

Imisebenzi Eyinhloko:Ingenza imisebenzi efana nokuxhuma amapayipi, ukushintsha indlela yokugeleza, ukuhlukanisa nokuhlanganisa ukugeleza, ukulungisa ububanzi bamapayipi, ukuvala amapayipi, ukulawula nokulawula.

Ububanzi Bokusetshenziswa:

- Ukwakhiwa kwamanzi kanye nokukhipha amanzi:Izindololwane ze-PVC kanye ne-PPR tris zisetshenziselwa amanethiwekhi amapayipi amanzi.

- Amapayipi ezimboni:Ama-flange ensimbi engagqwali kanye nezindololwane zensimbi ezixutshwe ngomlotha zisetshenziselwa ukuthutha izinto zamakhemikhali.

- Ukuthuthwa kwamandla:Izithako zamapayipi ensimbi anomfutho ophezulu zisetshenziswa emapayipini kawoyela negesi.

- I-HVAC (Ukushisa, Umoya Ongenisayo, kanye Nomoya Ongenisayo):Izithako zamapayipi ethusi zisetshenziselwa ukuxhuma amapayipi efriji, kanti amalunga aguquguqukayo asetshenziselwa ukunciphisa ukudlidliza.

- Ukunisela ngenkasa kwezolimo:Izixhumi ezisheshayo zenza kube lula ukuhlanganiswa nokuhlukaniswa kwezinhlelo zokunisela ezifafaza.