AMAPHARAMETHI OMKHIQIZO

| Igama Lomkhiqizo | Ingqiniba yepayipi |

| Usayizi | Ingqiniba engenamthungo engu-1/2"-36" (ingqiniba ye-SMLS), engu-26"-110" ihlanganiswe ngomthungo. Ububanzi obukhulu bangaphandle bungaba ngu-4000mm |

| Okujwayelekile | I-ANSI B16.9, EN10253-2, DIN2605, GOST17375-2001, JIS B2313, MSS SP 75, njll. |

| Ubukhulu bodonga | I-STD, i-XS, i-XXS, i-SCH20, i-SCH30, i-SCH40, i-SCH60, i-SCH80, i-SCH160, i-XXS njll. |

| Idigri | 30° 45° 60° 90° 180°, njll. |

| Irediyasi | Irediyasi ye-LR/endeshi/R=1.5D, Irediyasi ye-SR/endeshi emfushane/R=1D |

| Ukuphela | Isiphetho se-Bevel/BE/buttweld |

| Ubuso | umbala wemvelo, i-varnished, upende omnyama, uwoyela wokulwa nokugqwala njll. |

| Izinto | Insimbi yekhabhoni:I-A234WPB, A420 WPL6 St37,St45, E24, A42CP, 16Mn, Q345, P245GH,P235GH, P265GH, P280GH, P295GH, P355GH njll. |

| Insimbi yepayipi:I-ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65, WPHY70, WPHY80 njll. | |

| Insimbi ye-Cr-Mo alloy:A234 WP11, WP22, WP5, WP9, WP91, 10CrMo9-10, 16Mo3, 12crmov, njll. | |

| Isicelo | Imboni ye-Petrochemical; imboni yezindiza kanye nezindiza; imboni yezemithi, igesi ephumayo; isitshalo samandla; isakhiwo semikhumbi; ukwelashwa kwamanzi, njll. |

| Izinzuzo | isitoko esilungile, isikhathi sokulethwa esisheshayo; sitholakala ngosayizi bonke, senziwe ngokwezifiso; ikhwalithi ephezulu |

IZINTO ZOKWENZA AMAPHAYIPHI

Ukufakwa kwamapayipi ahlanganisiwe ngezinqe kufaka phakathi indololwane yepayipi yensimbi, i-tee yepayipi yensimbi, i-reduer yepayipi yensimbi, i-cap yepayipi yensimbi. Zonke lezo zingxenye zamapayipi okushisela izinqe, singazihlinzeka ndawonye, sinolwazi lokukhiqiza lweminyaka engama-20.

Uma unesithakazelo nakwezinye izinto zokufakelwa, sicela uchofoze ku-LINK elandelwayo ukuze uhlole imininingwane.

I-PIPE TEE ISINCISHISI SAMAPHAYIPHI ISIVALO SEPAYIPHI I-PIPE BEND IZINTO EZIFAKWE NGOKUQINISEKISA

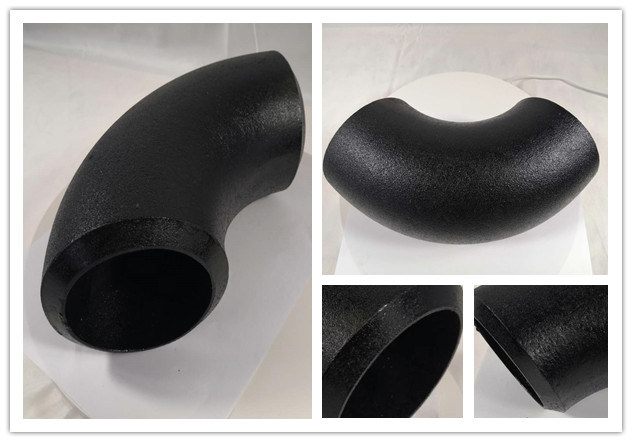

I-BUTT WLDED PIPE ELBOW

I-elbow yepayipi lensimbi iyizingxenye ezibalulekile ohlelweni lwamapayipi ukushintsha indlela yokugeleza koketshezi. Isetshenziselwa ukuxhuma amapayipi amabili anobubanzi obufanayo noma obuhlukile, nokwenza ipayipi liphendukele ohlangothini oluthile lwama-degree angu-45 noma angu-90.

Kumapayipi endololwane ezimbonini, uhlobo lwe-connectin end luyi-butt weld, ngokusho kwe-ANSI B16.25. I-Butt weld ingachaza i-butt welding, i-butweld, ne-bevel end. BW

UHLOBO LWESIBANDLA

Ingqiniba ingahle ihluke kusukela ekhoneni eliqondisiwe, izinhlobo zokuxhuma, ubude kanye nerediyasi, izinhlobo zezinto.

Kuhlukaniswe nge-Direction Angle

Njengoba sazi, ngokwesiqondiso soketshezi samapayipi, indololwane ingahlukaniswa ngamadigri ahlukene, njenge-degrees ezingama-45, 90, 180, okuyizingadi ezivame kakhulu. Futhi kune-degrees ezingama-60 kanye ne-120, kwamanye amapayipi akhethekile.

Ngendololwane engama-degree angu-90, kuchazwe nendololwane engama-90d, noma indololwane engama-degree angu-90.

Iyini i-Elbow Radius

Irediyasi yendololwane isho irediyasi egobile. Uma irediyasi ifana nobubanzi bepayipi, ibizwa ngokuthi i-short radius elbow, ebizwa nangokuthi i-SR elbow, ngokuvamile yamapayipi anengcindezi ephansi kanye nesivinini esiphansi.

Uma i-radius inkulu kunobubanzi bepayipi, i-R ≥ 1.5 Diameter, khona-ke siyibiza ngokuthi i-long radius elbow (LR Elbow), esetshenziselwa amapayipi okucindezela okuphezulu kanye nesivinini sokugeleza okuphezulu.

Uma irediyasi ingaphezu kuka-1.5D, njalo ibizwa ngokuthi ukugoba. Ukugoba kwendololwane kufanele kufakwe kumapayipi. Njengendololwane engu-2d, ukugoba okungu-2d, indololwane engu-3d, ukugoba okungu-3d, njll.

Ukuhlukaniswa Ngokwezinto Ezibalulekile

Insimbi yekhabhoni, ebizwa nangokuthi insimbi emnene noma insimbi emnyama. Njenge-ASTM A234 WPB

Uma ufuna izindololwane zensimbi engagqwali, sicela uchofoze lesi sixhumanisi ukuthola imininingwane eyengeziwe:IZINDLOVU ZENSITI ENGAGQI

Uhlobo Lomumo

Kungaba yindololwane elinganayo noma Ukunciphisa indololwane

UBUSO BE-ELBOW

Ukuqhuma Kwesihlabathi

Ngemva kokwakheka okushisayo, sihlela ukuqhuma kwesihlabathi ukuze senze indawo ihlanzeke futhi ibushelelezi.

Ngemva kokuqhuma kweSand, ukuze kugwenywe ukugqwala, kufanele upende omnyama noma uwoyela wokulwa nokugqwala, i-Hot dip galvanized (HDG), i-epoxy, i-3PE, indawo enyamalele, njll. Lokho kuncike esicelweni sekhasimende.

UKWELASHWA NGOKUSHISA

1. Gcina isampula yezinto zokusetshenziswa ukuze ulandelele.

2. Hlela ukwelashwa kokushisa ngokwezinga elijwayelekile.

UKUPHAWULA

Imisebenzi ehlukahlukene yokumaka, ingagoba, ipendwe, ibhalwe phansi. Noma ngesicelo sakho. Siyakwamukela ukumaka i-LOGO yakho.

IZITHOMBE EZINEMINININGWANE

1. Isiphetho se-Bevel ngokwe-ANSI B16.25.

2. Ukuqhuma kwesihlabathi kuqala, bese kuba umsebenzi omuhle wokupenda. Kungafakwa i-varnish.

3. Ngaphandle kwe-lamination kanye nemifantu.

4. Ngaphandle kokulungiswa kokushisela.

UKUHLOLA

1. Ukulinganiswa kobukhulu, konke kungaphakathi kokubekezelelana okujwayelekile.

2. Ukubekezelelana kobukhulu: +/- 12.5%, noma ngesicelo sakho

3. I-PMI

4. Ukuhlolwa kwe-MT, UT, i-X-ray

5. Yamukela ukuhlolwa komuntu wesithathu

6. Nikeza isitifiketi se-MTC, EN10204 3.1/3.2

UKUPHAKISHA NOKUTHUMELA

1. Ipakishwe ngebhokisi le-plywood noma i-plywood pallet ngokwe-ISPM15

2. sizobeka uhlu lokupakisha ephaketheni ngalinye

3. sizobeka izimpawu zokuthumela kuphakheji ngayinye. Amagama ezimpawu akhona ngokwesicelo sakho.

4. Zonke izinto zokupakisha izinkuni azinawo uphethiloli

Imibuzo Evame Ukubuzwa

1. Iyini i-ANSI B16.9?

I-ANSI B16.9 ibhekisela kumazinga e-American National Standards Institute (ANSI) okufakwa kwamapayipi okushintshwa kwe-butt-weld okwenziwe efektri. Icacisa ubukhulu, ukubekezelelana, izinto zokwakha kanye nezidingo zokuhlola zokufakwa kwamapayipi okushintshwa kwe-butt.

2. Ziyini izinto zokufaka amapayipi ahlanganisiwe ezinqeni?

Ukufakwa kwe-Butt weld kuyizinto zokufakelwa kwamapayipi ezixhunyelwe emaphethelweni amapayipi noma kwezinye izinto zokwakha ijoyinti eliqinile, elingavuzi. Ukuxhumeka kwe-butt weld kwenziwa ngokufaka ukuphela kwepayipi noma ukufakelwa kusokhethi lelinye ipayipi noma ukufakelwa kanye nokushisela ijoyinti.

3. Iyini indololwane yokushisela yensimbi yekhabhoni engu-180 degrees?

Insimbi yekhabhoni ehlanganisiwe engu-180 degree iwukufakwa kwepayipi okusetshenziselwa ukushintsha indlela ipayipi eliqondiswa ngayo ngama-degree angu-180. Itholakala ngemiklamo yerediyasi ende noma emifushane futhi yenziwe ngezinto zensimbi yekhabhoni. Sebenzisa uxhumano lwe-butt weld ukuxhuma indololwane nepayipi noma okunye ukufakwa.

4. Yiziphi izidingo zezindololwane ezihlanganisiwe ku-ANSI B16.9?

I-ANSI B16.9 icacisa ubukhulu, ukubekezelelana, izinto zokwakha, kanye nezidingo zokuhlola zezindololwane ezihlanganisiwe. Inikeza isiqondiso ngenqubo yokukhiqiza, kufaka phakathi ububanzi bangaphandle, ukujiya kodonga, ubukhulu obuphakathi kuya ekugcineni kanye nerediyasi yokugoba kwezindololwane ezinobukhulu obuhlukene.

5. Yiziphi izinzuzo zokusebenzisa insimbi yekhabhoni ukuze kufakwe amapayipi ahlanganisiwe ngezinqe?

Insimbi yekhabhoni isetshenziswa kabanzi ekufakweni kwamapayipi okushisiwe ngezinqe ngenxa yamandla ayo amahle kakhulu, ukuqina kanye nokumelana nokugqwala. Ingamelana nokucindezela okuphezulu kanye nezimo zokushisa okuphezulu futhi inokusebenza okuphezulu kakhulu. Ukufakwa kwensimbi yekhabhoni kufanelekela ukusetshenziswa okuhlukahlukene embonini kawoyela negesi, i-petrochemical kanye nokukhiqizwa kukagesi.

6. Ingabe insimbi yekhabhoni engu-180-degree ingasetshenziswa kokubili ezinhlelweni zokucindezela okuphezulu kanye nezinokucindezela okuphansi?

Yebo, izindololwane ezihlanganisiwe zensimbi yekhabhoni ezingama-degree angu-180 zingasetshenziswa kokubili ezinhlelweni zokucindezela okuphezulu nokuphansi. Kodwa-ke, isilinganiso sokucindezela esithile sendololwane kufanele sicatshangelwe ngokusekelwe ezidingweni zohlelo lokusebenza. Izesekeli kumele ziqinisekiswe ukuthi ziyahambisana yini nezingcindezi zesistimu ezilindelekile.

7. Ingabe indololwane ehlanganisiwe yensimbi yekhabhoni engama-degree angu-180 ifanelekile ezindaweni ezigqwalisayo?

Yebo, ukufakwa kwensimbi yekhabhoni ngokuvamile kufanelekile ukusetshenziswa ezindaweni ezigqwalisayo. Kodwa-ke, uhlobo kanye nokuhlushwa kwezinto ezigqwalisayo kufanele kucatshangelwe lapho kukhethwa izinto. Ezindaweni ezigqwalisayo kakhulu, kungadingeka ukuvikelwa okwengeziwe kokugqwala, njengezimbozo zangaphandle noma ama-lining.

8. Ingabe izindololwane zensimbi yekhabhoni ezingama-degree angu-180 zingasetshenziswa namapayipi enziwe ngezinye izinto?

Yebo, izingqimba zensimbi yekhabhoni ezihlanganisiwe ezingama-degree angu-180 zingasetshenziswa ngamapayipi enziwe ngensimbi engagqwali, insimbi ye-alloy, izinsimbi ezingezona i-ferrous nezinye izinto. Kodwa-ke, ukuze kusebenze isikhathi eside, kufanele kucatshangelwe ukuhambisana phakathi kwezinto kanye nemiphumela yokugqwala kwe-galvanic.

9. Yiziphi izivivinyo ezenziwe ezindololwaneni zensimbi yekhabhoni ye-ANSI B16.9 ezingama-degree angu-180?

I-ANSI B16.9 icacisa izivivinyo ezahlukahlukene ukuqinisekisa ikhwalithi kanye nobuqotho bezindololwane ezihlanganisiwe zensimbi yekhabhoni ezingama-degree angu-180. Lezi zivivinyo zingafaka ukuhlolwa kobukhulu, ukuhlolwa okubonakalayo, ukuhlolwa kwe-ultrasonic, ukuhlolwa kwamandla okudonsa, ukuhlolwa komthelela kanye nokuhlolwa okungabhubhisi (njengokungena kodayi noma ukuhlolwa kwe-radiographic).

10. Ingabe izindololwane zensimbi yekhabhoni ezingama-degree angu-180 zingashintshwa noma zishiselwe endaweni?

Izindololwane zensimbi yekhabhoni ezingama-degree angu-180 zingashintshwa noma zishiselwe ensimini kodwa kufanele zenziwe ngabasebenzi abaqeqeshiwe nabanolwazi ngokuhambisana nezindinganiso nezinqubo zomkhakha. Kunconywa ukubonisana nomkhiqizi noma unjiniyela ochwepheshe ukuze uthole isiqondiso sokuqinisekisa ukuphepha nokusebenza kwezesekeli ezishintshwayo.

Ukufakwa kwamapayipi kuyizinto ezibalulekile ohlelweni lwamapayipi, ezisetshenziselwa ukuxhuma, ukuqondisa kabusha, ukuphambukisa, ukushintsha usayizi, ukuvala noma ukulawula ukugeleza koketshezi. Zisetshenziswa kabanzi emikhakheni efana nokwakha, imboni, amandla kanye nezinsizakalo zikamasipala.

Imisebenzi Eyinhloko:Ingenza imisebenzi efana nokuxhuma amapayipi, ukushintsha indlela yokugeleza, ukuhlukanisa nokuhlanganisa ukugeleza, ukulungisa ububanzi bamapayipi, ukuvala amapayipi, ukulawula nokulawula.

Ububanzi Bokusetshenziswa:

- Ukwakhiwa kwamanzi kanye nokukhipha amanzi:Izindololwane ze-PVC kanye ne-PPR tris zisetshenziselwa amanethiwekhi amapayipi amanzi.

- Amapayipi ezimboni:Ama-flange ensimbi engagqwali kanye nezindololwane zensimbi ezixutshwe ngomlotha zisetshenziselwa ukuthutha izinto zamakhemikhali.

- Ukuthuthwa kwamandla:Izithako zamapayipi ensimbi anomfutho ophezulu zisetshenziswa emapayipini kawoyela negesi.

- I-HVAC (Ukushisa, Umoya Ongenisayo, kanye Nomoya Ongenisayo):Izithako zamapayipi ethusi zisetshenziselwa ukuxhuma amapayipi efriji, kanti amalunga aguquguqukayo asetshenziselwa ukunciphisa ukudlidliza.

- Ukunisela ngenkasa kwezolimo:Izixhumi ezisheshayo zenza kube lula ukuhlanganiswa nokuhlukaniswa kwezinhlelo zokunisela ezifafaza.

-

I-90 degree endololwaneni tee reducer carbon steel Butt w ...

-

isiphetho se-carbon steel sch80 butt esihlanganisiwe esingu-12 intshi sch4...

-

I-Asme b16.9 schedule 80 steel pipe fittings tee ...

-

insimbi yekhabhoni enciphileyo yokunciphisa i-ASTM A105 Emnyama ...

-

I-ANSI B16.9 Insimbi Yekhabhoni Egobile Ngamadigri angu-45 Ukugoba Kokushisela

-

Insimbi engagqwali i-long bend1d 1.5d 3d 5d radius 3...