IMIPHAKATHI YOMKHIQIZO

| Igama Lomkhiqizo | Isiphambano sepayipi |

| Usayizi | 1/2"-24" engenamthungo, 26"-110" eshiselwe |

| Okujwayelekile | ANSI B16.9, EN10253-2, DIN2615, GOST17376, JIS B2313, MSS SP 75, njll. |

| Ukujiya kodonga | STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS nokunye. |

| Uhlobo | kuyalingana/kuqondile, akulingani/kuyancishiswa/kuncishisiwe |

| Qeda | I-Bevel end/BE/buttweld |

| Ubuso | umbala wemvelo, i-varnished, umdwebo omnyama, uwoyela ophikisana nokugqwala njll. |

| Okubalulekile | Insimbi ye-Carbon:I-A234WPB, A420 WPL6 St37,St45, E24, A42CP, 16Mn, Q345, P245GH,P235GH, P265GH, P280GH, P295GH, P355GH njll. |

| Insimbi yepayipi:ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65,WPHY70, WPHY80 nokunye. | |

| Insimbi ye-Cr-Mo ingxubevange:I-A234 WP11, WP22, WP5, WP9, WP91, 10CrMo9-10, 16Mo3 njll. | |

| Isicelo | Imboni ye-petrochemical;imboni yezindiza kanye ne-aerospace;imboni yezemithi,i-gas exhaust;isikhungo sikagesi;isakhiwo somkhumbi;ukwelashwa kwamanzi, njll. |

| Izinzuzo | isitoko esilungile, isikhathi sokulethwa esisheshayo; sitholakala kuwo wonke amasayizi, enziwe ngokwezifiso; ikhwalithi ephezulu |

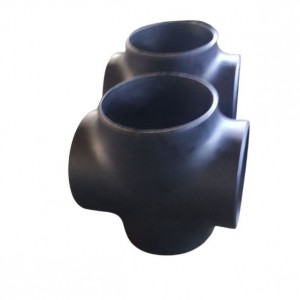

ISINGENISO ESIPHAMBANO

Iphambano lamapayipi uhlobo lokufakwa kwamapayipi okumise okwe-T okunezindawo zokuphuma ezimbili, ku-90° ekuxhumekeni komugqa omkhulu.Kuwucezu olufushane lwepayipi oluphuma eceleni.I-Pipe Tee isetshenziselwa ukuxhuma amapayipi ngepayipi nge-engeli engakwesokudla ngomugqa.Ama-Pipe Tees asetshenziswa kakhulu njengokufakwa kwamapayipi.Zenziwe ngezinto ezihlukahlukene futhi zitholakala ngobukhulu obuhlukahlukene kanye nokuqedwa.Amapayipi amapayipi asetshenziswa kakhulu kunethiwekhi yamapayipi ukuthutha ingxube yezigaba ezimbili zoketshezi.

UHLOBO LWEMPELA

- Kunamapayipi amapayipi aqondile anezikhala ezinosayizi ofanayo.

- Amapayipi amapayipi okunciphisa anokuvulwa okukodwa kosayizi ohlukile kanye nezimbobo ezimbili ezinosayizi ofanayo.

-

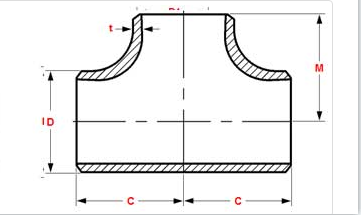

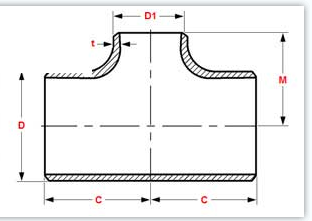

UKUBEKEZELEKA OKUHLE KWE-ASME B16.9 AMATIYE OKUQONDILE

Usayizi Wepayipi Lokuqamba 1/2 kuya ku-2.1/2 3 kuya ku-3.1/2 4 5 ku8 10 ku-18 20 ku24 26 ku30 32 ku48 Ngaphandle Dia

e-Bevel (D)+1.6

-0.81.6 1.6 +2.4

-1.6+4

-3.2+6.4

-4.8+6.4

-4.8+6.4

-4.8Ngaphakathi Dia at End 0.8 1.6 1.6 1.6 3.2 4.8 +6.4

-4.8+6.4

-4.8Maphakathi kuya ekupheleni (C / M) 2 2 2 2 2 2 3 5 I-Wall Thk (t) Hhayi ngaphansi kuka-87.5% Wokuqina Kwezindonga Ngezinga Ukubekezelela kobukhulu ngamamilimitha ngaphandle uma kuboniswe ngenye indlela futhi kuyalingana ± ngaphandle kwalapho kuphawuliwe.

UKUHLOLA

1. Izilinganiso zobukhulu, zonke zingaphakathi kokubekezelelana okujwayelekile.

2. Ukubekezelela ukuqina:+/-12.5% , noma ngokwesicelo sakho

3. I-PMI

4. MT, UT,PT, X-ray test

5. Yamukela ukuhlolwa komuntu wesithathu

6. Faka isitifiketi se-MTC, EN10204 3.1/3.2

UKUPAKASHA NOKUTHUMELA

1. Ipakishwe ngekesi le-plywood noma i-plywood pallet ngokwe-ISPM15

2. sizobeka uhlu lokupakisha kuphakheji ngayinye

3. sizofaka izimpawu zokuthumela kuphakheji ngayinye.Amagama omaka asesicelweni sakho.

4. Zonke izinto zephakeji lezinkuni azifuzi mahhala

FAQ

1.Iyini i-ASME B16.9?

I-ASME B16.9 iyindinganiso eyathuthukiswa yi-American Society of Mechanical Engineers (ASME) emboza okokufakwa kwezinqe okwenziwe efekthri.Inikeza ubukhulu, ukubekezelela kanye nokucaciswa kwezinto ezibonakalayo zezinhlobo ezahlukene zokufakwa kwe-butt weld.

2.Iyini i-A105?

I-A105 iwukucaciswa kwe-carbon steel forgings esetshenziswa ezingxenyeni zomkhumbi wengcindezi.Ihlanganisa izingxenye zamapayipi ensimbi enziwe ngensimbi yemvelo kanye nesevisi yokushisa okuphezulu kumasistimu okucindezela.

3. Yini i-A234WPB?

I-A234WPB iwuphawu lokufakwa kwamapayipi ensimbi ekhabhoni kanye nengxubevange esetshenziswa emazingeni okushisa aphakathi nendawo naphezulu.Lokhu kufakwa kwenziwa kusetshenziswa izindlela zokwakha ezingenamthungo noma ezishiselwe futhi ngokuvamile zisetshenziswa ezinhlelweni zamapayipi.

4. Yini isinqamu esishiselwe esiphambanweni esiyidayamitha esilinganayo?

Isiphambano se-Butt weld esilinganayo se-diameter silinganisa ipayipi esetshenziselwa ukuhlinzeka ukuxhumana kwegatsha ezinhlelweni zamapayipi.Inezikhala ezine ezinobukhulu obulinganayo, indawo yokungena eyodwa kanye nezindawo zokuphuma ezintathu ezihlelwe ngendlela eyisiphambano.Ivumela uketshezi ukuthi lugeleze ngezindlela ezihlukene futhi ivame ukusetshenziswa emapayipini anqamula.

5. Iyini impahla yesakhiwo ye-ASME B16.9 A105 A234WPB carbon steel butt eshiselwe isiphambano esiyidayamitha esilinganayo?

I-ASME B16.9 A105 A234WPB i-carbon steel butt welding isiphambano esilingana nodayamitha yenziwe ngezinto ze-carbon steel, ikakhulukazi ama-forging yi-A105 kanye nokufakwa kwamapayipi kungu-A234WPB.Lezi zinto zaziwa ngamandla azo, ukuqina, nokungagqwali.

6. Yimaphi amasayizi atholakalayo ku-ASME B16.9 A105 A234WPB carbon steel butt weld iziphambano ezinobubanzi obulinganayo?

I-ASME B16.9 A105 A234WPB I-Carbon Steel Butt Weld Equal Diameter Crosses itholakala ngamasayizi ahlukahlukene ukusuka kumadayimitha amancane kuya amakhulu.Ubukhulu obuthile buncike ezidingweni zohlelo lwamapayipi futhi kungenziwa ngendlela oyifisayo.

7. Siyini isilinganiso sokucindezela se-ASME B16.9 A105 A234WPB carbon steel butt esishiselwe isiphambano esilinganayo?

ASME B16.9 A105 A234WPB Izilinganiso zokucindezela ze-carbon steel butt weld iziphambano ezinobubanzi obulinganayo ziyahlukahluka kuye ngobukhulu, into kanye nezimo zezinga lokushisa.Lezi zilinganiso zokucindezela zicaciswe kuzinga le-ASME B16.9 futhi kufanele lilandelwe ukuze kuqinisekiswe ukusebenza okuphephile nokuthembekile.

8. Ingabe i-ASME B16.9 A105 A234WPB i-carbon steel butt weld ye-diameter elinganayo isiphambano ingasetshenziswa kukho kokubili izinga lokushisa eliphezulu neliphansi?

Yebo, i-ASME B16.9 A105 A234WPB i-carbon steel butt weld iziphambano ezinobubanzi obulinganayo ziyatholakala kukho kokubili izinga lokushisa eliphezulu neliphansi.Kodwa-ke, kubalulekile ukukhetha izinto ezifanele futhi uqinisekise ukuthi izinga lokushisa lokuklama nokucindezela kuyahlangatshezwa.

9. Ingabe i-ASME B16.9 A105 A234WPB yensimbi yensimbi butt eshiselwe isiphambano esiyidayamitha esilinganayo ifaneleka endaweni ebolayo?

I-ASME B16.9 A105 A234WPB isinqe sensimbi ye-carbon steel esishiselwe isiphambano esinobubanzi obulinganayo singasetshenziswa ezindaweni ezigqwala kancane.Kodwa-ke, ezindaweni ezigqwalile kakhulu, kunconywa ukusebenzisa izinto ezimelana nokugqwala noma ukufaka izimbotshana zokuvikela ezengeziwe ukuze kwandiswe impilo yesevisi yezinsiza.

10. Ingabe i-ASME B16.9 A105 A234WPB carbon steel butt eshiselwe iziphambano ezinobubanzi obulinganayo zisetshenziswa kabanzi?

Yebo, i-ASME B16.9 A105 A234WPB I-Carbon Steel Butt Weld Contour Cross itholakala kabanzi kubakhiqizi, abahlinzeki nabasabalalisi abagunyaziwe.Kubalulekile ukuwathenga emithonjeni ehloniphekile ukuze uqinisekise ukuthi amazinga ekhwalithi kanye nokucaciswa kuyahlangatshezwana nayo.

-

304 304L 321 316 316L insimbi engagqwali 90 degree...

-

I-White Steel Pipe Reducer SCH 40 Stainless Steel...

-

carbon steel lokushisa low lokushisa steel bend indololwane w ...

-

ASME B16.9 A234 SCH 40 STD Izinqe Ezishiselwe ikhabhoni...

-

Insimbi engagqwali 45/60/90/180 Degree Elbow

-

sch80 ss316 insimbi engagqwali Butt Weld Eccentri...