AMAPHARAMETHI OMKHIQIZO

| Igama Lomkhiqizo | Isiphambano sepayipi |

| Usayizi | 1/2"-24" engenamthungo, 26"-110" ehlanganisiwe |

| Okujwayelekile | I-ANSI B16.9, EN10253-2, DIN2615, GOST17376, JIS B2313, MSS SP 75, njll. |

| Ubukhulu bodonga | I-STD, i-XS, i-XXS, i-SCH20, i-SCH30, i-SCH40, i-SCH60, i-SCH80, i-SCH160, i-XXS njll. |

| Uhlobo | ngokulinganayo/okuqondile, okungalingani/okunciphisa/okunciphisa |

| Ukuphela | Isiphetho se-Bevel/BE/buttweld |

| Ubuso | umbala wemvelo, i-varnished, upende omnyama, uwoyela wokulwa nokugqwala njll. |

| Izinto | Insimbi yekhabhoni:I-A234WPB, A420 WPL6 St37,St45, E24, A42CP, 16Mn, Q345, P245GH,P235GH, P265GH, P280GH, P295GH, P355GH njll. |

| Insimbi yepayipi:I-ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65, WPHY70, WPHY80 njll. | |

| Insimbi ye-Cr-Mo alloy:A234 WP11, WP22, WP5, WP9, WP91, 10CrMo9-10, 16Mo3 njll. | |

| Isicelo | Imboni ye-Petrochemical; imboni yezindiza kanye nezindiza; imboni yezemithi, igesi ephumayo; isitshalo samandla; isakhiwo semikhumbi; ukwelashwa kwamanzi, njll. |

| Izinzuzo | isitoko esilungile, isikhathi sokulethwa esisheshayo; sitholakala ngosayizi bonke, senziwe ngokwezifiso; ikhwalithi ephezulu |

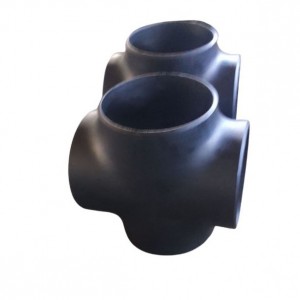

ISINGENISO SESIPHAMBANO

Isiphambano sepayipi uhlobo lokufakwa kwepayipi olunomumo we-T olunezindawo ezimbili zokuphuma, ku-90° ekuxhumekeni komugqa oyinhloko. Luyipayipi elifushane elinokuphuma eceleni. I-Pipe Tee isetshenziselwa ukuxhuma amapayipi ngepayipi ekhoneni lesokudla nomugqa. Ama-Pipe Tee asetshenziswa kabanzi njengezindawo zokufaka amapayipi. Enziwe ngezinto ezahlukene futhi atholakala ngobukhulu obuhlukahlukene kanye nokuqedwa. Ama-Pipe Tee asetshenziswa kakhulu kumanethiwekhi amapayipi ukuthutha izingxube zoketshezi zezigaba ezimbili.

UHLOBO LWESIPHAMBANO

- Kukhona ama-tee epayipi aqondile anezikhala ezilinganayo ngobukhulu.

- Ama-tee epayipi okunciphisa anomgodi owodwa onobukhulu obuhlukile kanye nezimbobo ezimbili ezinobukhulu obufanayo.

-

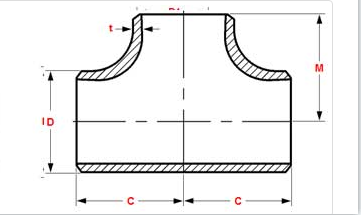

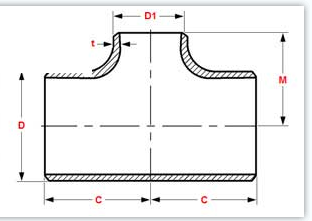

UKUBEKEZELELA OKUNEMIKHAWULO KWAMA-ASME B16.9 STRATE TEES

Usayizi Wepayipi Ojwayelekile 1/2 kuya ku-2.1/2 3 kuya ku-3.1/2 4 5 kuya ku-8 10 kuya ku-18 20 kuya ku-24 26 kuya ku-30 32 kuya ku-48 Ngaphandle kweDia

eBevel (D)+1.6

-0.81.6 1.6 +2.4

-1.6+4

-3.2+6.4

-4.8+6.4

-4.8+6.4

-4.8Ngaphakathi kwe-Dia Ekupheleni 0.8 1.6 1.6 1.6 3.2 4.8 +6.4

-4.8+6.4

-4.8Isikhungo Sokuphela (C / M) 2 2 2 2 2 2 3 5 I-Wall Thk (t) Okungenani ngaphansi kuka-87.5% wobukhulu bodonga obujwayelekile Ukubekezelelana kobukhulu kungamamilimitha ngaphandle kokuthi kuboniswe ngenye indlela futhi kuyalingana ± ngaphandle kokuthi kuphawuliwe.

UKUHLOLA

1. Ukulinganiswa kobukhulu, konke kungaphakathi kokubekezelelana okujwayelekile.

2. Ukubekezelelana kobukhulu: +/- 12.5%, noma ngesicelo sakho

3. I-PMI

4. Ukuhlolwa kwe-MT, UT, PT, X-ray

5. Yamukela ukuhlolwa komuntu wesithathu

6. Nikeza isitifiketi se-MTC, EN10204 3.1/3.2

UKUPHAKISHA NOKUTHUMELA

1. Ipakishwe ngebhokisi le-plywood noma i-plywood pallet ngokwe-ISPM15

2. sizobeka uhlu lokupakisha kuphakheji ngayinye

3. sizobeka izimpawu zokuthumela kuphakheji ngayinye. Amagama ezimpawu akhona ngokwesicelo sakho.

4. Zonke izinto zokupakisha izinkuni azinawo uphethiloli

Imibuzo Evame Ukubuzwa

1. Iyini i-ASME B16.9?

I-ASME B16.9 iyindinganiso ethuthukiswe yi-American Society of Mechanical Engineers (ASME) ehlanganisa ukufakwa kwe-butt weld okwenziwe efektri. Ihlinzeka ngobukhulu, ukubekezelelana kanye nemininingwane yezinto zokwakha zezinhlobo ezahlukene ze-butt weld fittings.

2. Kuyini i-A105?

I-A105 iyincazelo yezinto zokufakelwa kwensimbi yekhabhoni ezisetshenziswa ezingxenyeni zemikhumbi yokucindezela. Ihlanganisa izingxenye zamapayipi ensimbi yekhabhoni ezenziwe ngensimbi yokuvikela imvelo kanye nensizakalo yokushisa okuphezulu ezinhlelweni zokucindezela.

3. Kuyini i-A234WPB?

I-A234WPB iyincazelo yokufakwa kwamapayipi ensimbi yekhabhoni ne-alloy asetshenziswa emazingeni okushisa aphakathi naphezulu. Lokhu kufakwa kukhiqizwa kusetshenziswa izindlela zokwakha ezingenamthungo noma ezihlanganisiwe futhi ngokuvamile kusetshenziswa ezinhlelweni zamapayipi.

4. Iyini isiphambano esihlanganisiwe esilingana nobubanzi obuhlanganisiwe?

Isiphambano se-Butt weld esilingana nobubanzi siwukufakwa kwamapayipi okusetshenziselwa ukuhlinzeka ngokuxhumeka kwamagatsha ezinhlelweni zamapayipi. Sinezimbobo ezine ezilinganayo ngobukhulu, umnyango owodwa kanye nezindawo zokuphuma ezintathu ezihlelwe ngesimo sesiphambano. Sivumela uketshezi ukuthi lugeleze ngezindlela ezahlukene futhi sivame ukusetshenziswa kumapayipi ahlanganayo.

5. Iyini impahla yesakhiwo se-ASME B16.9 A105 A234WPB carbon steel butt welded equal diameter cross?

I-ASME B16.9 A105 A234WPB Ukushisela izinqe zensimbi yekhabhoni ububanzi obulinganayo kwenziwa ngezinto zensimbi yekhabhoni, ikakhulukazi izinto zokufakelwa yi-A105 kanti izihlanganisi zamapayipi yi-A234WPB. Lezi zinto zaziwa ngamandla azo, ukuqina, kanye nokumelana nokugqwala.

6. Yiziphi izilinganiso ezitholakalayo ze-ASME B16.9 A105 A234WPB carbon steel butt weld equivalent diameter crosses?

I-ASME B16.9 A105 A234WPB I-Carbon Steel Butt Weld Equal Diameter Crosss iyatholakala ngobukhulu obuhlukahlukene kusukela kobukhulu obuncane kuya kobukhulu. Ubukhulu obuthile buxhomeke ezidingweni zesistimu yamapayipi futhi bungenziwa ngokwezifiso ngokufanele.

7. Iyini isilinganiso sokucindezela se-ASME B16.9 A105 A234WPB carbon steel butt welded equal diameter cross?

Izilinganiso zokucindezela ze-ASME B16.9 A105 A234WPB ze-carbon steel butt weld equivalent diameter crosses ziyahlukahluka ngokuya ngobukhulu, izinto zokwakha kanye nezimo zokushisa. Lezi zilinganiso zokucindezela zichazwe ku-ASME B16.9 standard futhi kufanele zilandelwe ukuqinisekisa ukusebenza okuphephile nokuthembekile.

8. Ingabe i-ASME B16.9 A105 A234WPB carbon steel butt weld equivalent diameter cross ingasetshenziswa kokubili ekusetshenzisweni kwezinga lokushisa eliphezulu neliphansi?

Yebo, iziphambano ze-ASME B16.9 A105 A234WPB zensimbi yekhabhoni ezihlanganisiwe ezilinganayo nobubanzi ziyatholakala kokubili ekusetshenzisweni kokushisa okuphezulu nokuphansi. Kodwa-ke, kubalulekile ukukhetha izinto ezifanele nokuqinisekisa ukuthi izidingo zokushisa nokucindezela komklamo ziyahlangatshezwa.

9. Ingabe i-ASME B16.9 A105 A234WPB carbon steel butt welded equivalent diameter cross ifanelekela izindawo ezigqwalisayo?

I-ASME B16.9 A105 A234WPB insimbi yekhabhoni ehlanganisiwe enobubanzi obulinganayo ingasetshenziswa ezindaweni ezingcolisa kancane. Kodwa-ke, ezindaweni ezingcolisa kakhulu, kunconywa ukusebenzisa izinto ezingagqwali noma ukufaka izembozo ezengeziwe zokuvikela ukwandisa impilo yesevisi yezesekeli.

10. Ingabe iziphambano zensimbi yekhabhoni ezihlanganisiwe ze-ASME B16.9 A105 A234WPB zisetshenziswa kabanzi?

Yebo, i-ASME B16.9 A105 A234WPB Carbon Steel Butt Weld Contour Cross itholakala kabanzi ngabakhiqizi abagunyaziwe, abaphakeli kanye nabasabalalisi. Kubalulekile ukuzithenga emithonjeni ethembekile ukuqinisekisa ukuthi amazinga ekhwalithi kanye nemininingwane kuyahlangatshezwana.

Ukufakwa kwamapayipi kuyizinto ezibalulekile ohlelweni lwamapayipi, ezisetshenziselwa ukuxhuma, ukuqondisa kabusha, ukuphambukisa, ukushintsha usayizi, ukuvala noma ukulawula ukugeleza koketshezi. Zisetshenziswa kabanzi emikhakheni efana nokwakha, imboni, amandla kanye nezinsizakalo zikamasipala.

Imisebenzi Eyinhloko:Ingenza imisebenzi efana nokuxhuma amapayipi, ukushintsha indlela yokugeleza, ukuhlukanisa nokuhlanganisa ukugeleza, ukulungisa ububanzi bamapayipi, ukuvala amapayipi, ukulawula nokulawula.

Ububanzi Bokusetshenziswa:

- Ukwakhiwa kwamanzi kanye nokukhipha amanzi:Izindololwane ze-PVC kanye ne-PPR tris zisetshenziselwa amanethiwekhi amapayipi amanzi.

- Amapayipi ezimboni:Ama-flange ensimbi engagqwali kanye nezindololwane zensimbi ezixutshwe ngomlotha zisetshenziselwa ukuthutha izinto zamakhemikhali.

- Ukuthuthwa kwamandla:Izithako zamapayipi ensimbi anomfutho ophezulu zisetshenziswa emapayipini kawoyela negesi.

- I-HVAC (Ukushisa, Umoya Ongenisayo, kanye Nomoya Ongenisayo):Izithako zamapayipi ethusi zisetshenziselwa ukuxhuma amapayipi efriji, kanti amalunga aguquguqukayo asetshenziselwa ukunciphisa ukudlidliza.

- Ukunisela ngenkasa kwezolimo:Izixhumi ezisheshayo zenza kube lula ukuhlanganiswa nokuhlukaniswa kwezinhlelo zokunisela ezifafaza.

-

Insimbi engagqwali i-long bend1d 1.5d 3d 5d radius 3...

-

Ipayipi lensimbi elimnyama elingenamthungo le-A234WPB elifanela u-uqu ...

-

I-3050mm API 5L X70 WPHY70 Ingqiniba yokulinganisa ipayipi elihlanganisiwe

-

I-DN50 50A sch10 90 ipayipi lendololwane elifanela imithungo ye-LR ...

-

I-flange yensimbi engagqwali engenamthungo engu-321ss ...

-

insimbi yekhabhoni engu-45 degree bend 3d bw 12.7mm WT AP...