ISICELO

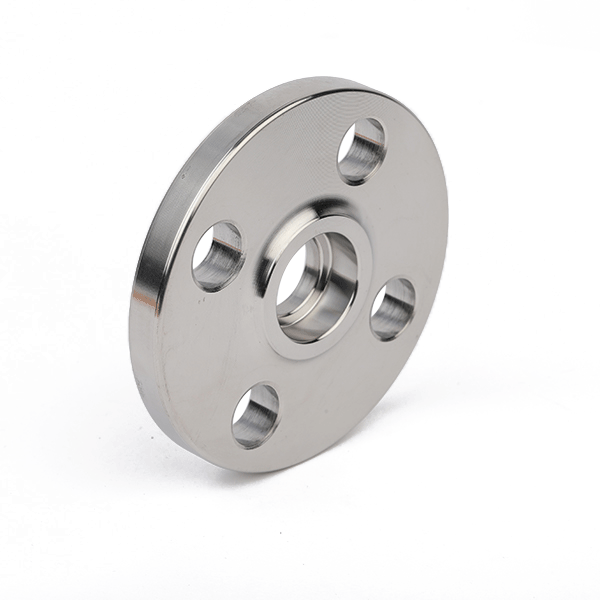

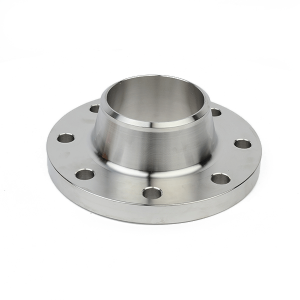

| Igama Lomkhiqizo | i-flange ye-socket weld |

| Usayizi | 1/2"-24" |

| Ingcindezi | 150#-2500#,PN0.6-PN400,5K-40K |

| Okujwayelekile | I-ANSI B16.5, EN1092-1, JIS B2220 njll. |

| Ubukhulu bodonga | SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS nokunye. |

| Izinto | Insimbi engagqwali:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo njalo njalo. |

| Insimbi yekhabhoni:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 njll. | |

| Insimbi engagqwali ephindwe kabili:I-UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 njll. | |

| Insimbi yepayipi:I-A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 njll. | |

| Ingxubevange ye-nickel:i-inconel600, i-inconel625, i-inconel690, i-incoloy800, i-incoloy 825, i-incoloy 800H,C22, C-276, i-Monel400, i-Alloy20 njll. | |

| Ingxubevange ye-Cr-Mo:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, njll. | |

| Isicelo | Imboni ye-Petrochemical; imboni yezindiza kanye nezindiza; imboni yemithi; ukukhishwa kwegesi; isitshalo samandla; isakhiwo semikhumbi; ukwelashwa kwamanzi, njll. |

| Izinzuzo | isitoko esilungile, isikhathi sokulethwa esisheshayo; sitholakala ngosayizi bonke, senziwe ngokwezifiso; ikhwalithi ephezulu |

AMAZINGA OKUDINGEKA

UMBONO WEMINININGWANE YEMIKHIQIZO

1. Ubuso

Kungaba ubuso obuphakanyisiwe (RF), ubuso obugcwele (FF), i-Ring joint (RTJ), i-Groove, ulimi, noma kwenziwe ngokwezifiso.

2. Ukushisela kwesokhethi

3. I-CNC fine iqediwe

Ukuphela kobuso: Ukuphela kobuso be-flange kulinganiswa njengokuphakama kwesilinganiso sobunzima be-Arithmetical (AARH). Ukuphela kunqunywa ngokwezinga elisetshenzisiwe. Isibonelo, i-ANSI B16.5 icacisa ukuqeda kobuso ngaphakathi kwebanga elingu-125AARH-500AARH (3.2Ra kuya ku-12.5Ra). Okunye ukuqeda kuyatholakala uma kufunwa, isibonelo u-1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra noma u-6.3/12.5Ra. Ububanzi obungu-3.2/6.3Ra buvame kakhulu.

UKUMAKISHA NOKUPHAKISHA

• Isendlalelo ngasinye sisebenzisa ifilimu yepulasitiki ukuvikela indawo engaphezulu

• Kuzo zonke izinsimbi ezingagqwali zipakishwa nge-plywood case. Ukuze kube ne-carbon flange enkulu zipakishwa nge-plywood pallet. Noma zingapakishwa ngendlela oyifisayo.

• Uphawu lokuthumela lungenza uma luceliwe

• Izimpawu emikhiqizweni zingabazwa noma ziphrintwe. I-OEM iyamukelwa.

UKUHLOLA

• Ukuhlolwa kwe-UT

• Ukuhlolwa kwe-PT

• Ukuhlolwa kwe-MT

• Ukuhlolwa kobukhulu

Ngaphambi kokulethwa, ithimba lethu le-QC lizohlela ukuhlolwa kwe-NDT kanye nokuhlolwa kobukhulu. Futhi lamukela i-TPI (ukuhlolwa komuntu wesithathu).

INKQUBO YOKUKHIQIZWA

| 1. Khetha izinto zokusetshenziswa zangempela | 2. Sika izinto zokusetshenziswa | 3. Ukushisa kusengaphambili |

| 4. Ukwakha | 5. Ukwelashwa ngokushisa | 6. Umshini Onzima |

| 7. Ukubhoboza | 8. Ukubumba kahle | 9. Ukumaka |

| 10. Ukuhlolwa | 11. Ukupakisha | 12. Ukulethwa |

Imibuzo Evame Ukubuzwa

1. Iyini i-ANSI B16.5 forged stainless steel socket weld flange?

I-ANSI B16.5 I-Flange Yensimbi Engagqwali Engagqwali Ehlanganisiwe iyi-flange esetshenziselwa ukuhlanganisa amapayipi ekusetshenzisweni komfutho ophezulu. Yenziwe ngensimbi engagqwali eyenziwe ngokuhlanganiswa kwe-socket weld ukuze kube lula ukuyifaka.

2. Ama-flange e-weld ensimbi engagqwali e-ANSI B16.5 ahluke kanjani kwezinye izinhlobo ze-flange?

Ngokungafani nezinye izinhlobo ze-flange, ama-flange e-ANSI B16.5 akhiwe ngensimbi engagqwali adinga uxhumano lwe-socket weld lapho ipayipi lifakwa khona ku-flange bese lihlanganiswa ngaphakathi. Lokhu kunikeza ijoyinti eqinile nengavuzi.

3. Yiziphi izinzuzo zokusebenzisa ama-flange e-weld ensimbi engagqwali enziwe nge-ANSI B16.5?

Izinzuzo ezibalulekile zokusebenzisa ama-flange ensimbi engagqwali enziwe nge-ANSI B16.5 afaka phakathi amandla aphezulu, ukuthembeka kanye nokumelana nokugqwala okuhle kakhulu. Alungele ukusetshenziswa okudinga amalunga aqinile futhi aqinile.

4. Yiziphi izimboni ezivame ukusebenzisa ama-flange okushisela insimbi engagqwali eyenziwe nge-ANSI B16.5?

Ama-flange ensimbi engagqwali enziwe nge-ANSI B16.5 avame ukusetshenziswa embonini kawoyela negesi, i-petrochemical, i-chemical, i-power generation kanye ne-water treatment. Afanele ukusetshenziswa komfutho ophezulu kanye nokushisa okuphezulu.

5. Ingabe ama-flange e-weld ensimbi engagqwali enziwe nge-ANSI B16.5 angasetshenziswa ekusetshenzisweni kwegesi noketshezi?

Yebo, ama-flange ensimbi engagqwali enziwe nge-ANSI B16.5 ayatholakala ukuze asetshenziswe ngegesi kanye noketshezi. Aklanyelwe ukuhlinzeka ngoxhumano oluphephile futhi angamelana nezidingo zokucindezela kanye nokushisa kohlobo olubanzi loketshezi.

6. Yiziphi izindinganiso ezilandelwayo ekwenziweni kwama-flange ensimbi engagqwali enziwe nge-ANSI B16.5?

Ama-flange e-ANSI B16.5 Forged Stainless Steel Socket Weld akhiqizwa ngokwezindinganiso ezisungulwe yi-American National Standards Institute (ANSI). Lezi zindinganiso ziqinisekisa ukuthi ama-flange ahlangabezana nezidingo zekhwalithi kanye nokusebenza ezidingekayo.

7. Ingabe ama-flange e-weld ensimbi engagqwali enziwe nge-ANSI B16.5 atholakala ngobukhulu obuhlukene kanye nezilinganiso zokucindezela?

Yebo, ama-flange e-weld ensimbi engagqwali enziwe nge-ANSI B16.5 atholakala ngobukhulu obuhlukahlukene kanye nezilinganiso zokucindezela. Lokhu kuvumela ukuguquguquka nokuhambisana nezinhlelo ezahlukene zamapayipi kanye nezidingo.

8. Ingabe ama-flange e-weld ensimbi engagqwali e-ANSI B16.5 angasetshenziswa ekuxhumeni okuphakanyisiwe nokuyisicaba?

Yebo, ama-flange ensimbi engagqwali enziwe nge-ANSI B16.5 ayatholakala kokubili ekuxhumeni ubuso obuphakanyisiwe kanye nobuso obuyisicaba. Ubuso be-Flange bungenziwa ngokwezifiso ukuze kuhlangatshezwane nezidingo ezithile zohlelo lokusebenza.

9. Ingabe ama-flange e-weld ensimbi engagqwali enziwe nge-ANSI B16.5 afanele ukusetshenziswa ekushiseni okuphezulu?

Yebo, ama-flange ensimbi engagqwali enziwe nge-ANSI B16.5 afanele ukusetshenziswa ekushiseni okuphezulu. Aklanyelwe ukumelana namazinga okushisa aphezulu ngaphandle kokuthinta ubuqotho bawo besakhiwo.

10. Kufanele zifakwe kanjani izingcezu ze-weld zensimbi engagqwali ze-ANSI B16.5?

Ama-flange e-socket weld ensimbi engagqwali e-ANSI B16.5 akhiwe kufanele afakwe ngendlela yokuthi ipayipi lifakwe ku-socket weld bese lihlanganiswa ngaphakathi. Kubalulekile ukuqinisekisa ukuthi kufezwa ukushintshwa okufanele ukuze kugcinwe amandla nobuqotho bokuxhumeka.

Imininingwane yemikhiqizo iboniswa

1. Ubuso

Kungaba ubuso obuphakanyisiwe (RF), ubuso obugcwele (FF), i-Ring joint (RTJ), i-Groove, ulimi, noma kwenziwe ngokwezifiso.

2. Ukushisela kwesokhethi

3. I-CNC fine iqediwe

Ukuphela kobuso: Ukuphela kobuso be-flange kulinganiswa njengokuphakama kwesilinganiso sobunzima be-Arithmetical (AARH). Ukuphela kunqunywa ngokwezinga elisetshenzisiwe. Isibonelo, i-ANSI B16.5 icacisa ukuqeda kobuso ngaphakathi kwebanga elingu-125AARH-500AARH (3.2Ra kuya ku-12.5Ra). Okunye ukuqeda kuyatholakala uma kufunwa, isibonelo u-1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra noma u-6.3/12.5Ra. Ububanzi obungu-3.2/6.3Ra buvame kakhulu.

Ukumaka Nokupakisha

• Isendlalelo ngasinye sisebenzisa ifilimu yepulasitiki ukuvikela indawo engaphezulu

• Kuzo zonke izinsimbi ezingagqwali zipakishwa nge-plywood case. Ukuze kube ne-carbon flange enkulu zipakishwa nge-plywood pallet. Noma zingapakishwa ngendlela oyifisayo.

• Uphawu lokuthumela lungenza uma luceliwe

• Izimpawu emikhiqizweni zingabazwa noma ziphrintwe. I-OEM iyamukelwa.

Ukuhlolwa

• Ukuhlolwa kwe-UT

• Ukuhlolwa kwe-PT

• Ukuhlolwa kwe-MT

• Ukuhlolwa kobukhulu

Ngaphambi kokulethwa, ithimba lethu le-QC lizohlela ukuhlolwa kwe-NDT kanye nokuhlolwa kobukhulu. Futhi lamukela i-TPI (ukuhlolwa komuntu wesithathu).

Inqubo yokukhiqiza

| 1. Khetha izinto zokusetshenziswa zangempela | 2. Sika izinto zokusetshenziswa | 3. Ukushisa kusengaphambili |

| 4. Ukwakha | 5. Ukwelashwa ngokushisa | 6. Umshini Onzima |

| 7. Ukubhoboza | 8. Ukubumba kahle | 9. Ukumaka |

| 10. Ukuhlolwa | 11. Ukupakisha | 12. Ukulethwa |

Ukufakwa kwamapayipi kuyizinto ezibalulekile ohlelweni lwamapayipi, ezisetshenziselwa ukuxhuma, ukuqondisa kabusha, ukuphambukisa, ukushintsha usayizi, ukuvala noma ukulawula ukugeleza koketshezi. Zisetshenziswa kabanzi emikhakheni efana nokwakha, imboni, amandla kanye nezinsizakalo zikamasipala.

Imisebenzi Eyinhloko:Ingenza imisebenzi efana nokuxhuma amapayipi, ukushintsha indlela yokugeleza, ukuhlukanisa nokuhlanganisa ukugeleza, ukulungisa ububanzi bamapayipi, ukuvala amapayipi, ukulawula nokulawula.

Ububanzi Bokusetshenziswa:

- Ukwakhiwa kwamanzi kanye nokukhipha amanzi:Izindololwane ze-PVC kanye ne-PPR tris zisetshenziselwa amanethiwekhi amapayipi amanzi.

- Amapayipi ezimboni:Ama-flange ensimbi engagqwali kanye nezindololwane zensimbi ezixutshwe ngomlotha zisetshenziselwa ukuthutha izinto zamakhemikhali.

- Ukuthuthwa kwamandla:Izithako zamapayipi ensimbi anomfutho ophezulu zisetshenziswa emapayipini kawoyela negesi.

- I-HVAC (Ukushisa, Umoya Ongenisayo, kanye Nomoya Ongenisayo):Izithako zamapayipi ethusi zisetshenziselwa ukuxhuma amapayipi efriji, kanti amalunga aguquguqukayo asetshenziselwa ukunciphisa ukudlidliza.

- Ukunisela ngenkasa kwezolimo:Izixhumi ezisheshayo zenza kube lula ukuhlanganiswa nokuhlukaniswa kwezinhlelo zokunisela ezifafaza.

-

Insimbi Engagqwali 304 304L 316 316L ASTM eyenziwe ngobumba...

-

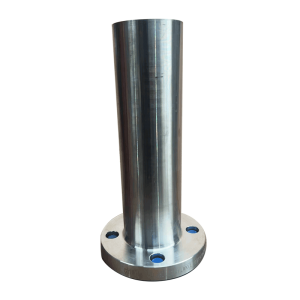

I-flange yobuso obuphakanyisiwe yokushisela yensimbi EN1092-1 uhlobo0 ...

-

insimbi engagqwali 304 316 304L 316L 317 Ipayipi Lokufaka...

-

I-Long Weld Neck Flange Standard Pressure LWN Ye ...

-

I-Flange ANSI/ASME/JIS Standard Carbon eyenziwe ngokwezifiso ...

-

i-carbon steel a105 forge blind flange