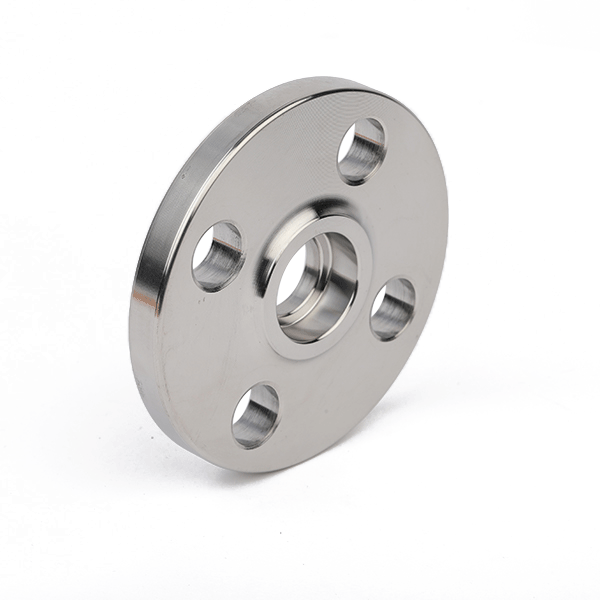

INKCAZO

| Igama Lomkhiqizo | isokhethi weld flange |

| Usayizi | 1/2"-24" |

| Ingcindezi | 150#-2500#,PN0.6-PN400,5K-40K |

| Okujwayelekile | I-ANSI B16.5,EN1092-1, JIS B2220 njll. |

| Ukujiya kodonga | SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS nokunye. |

| Okubalulekile | Insimbi engagqwali:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1, 1,4347 1.4571,1.4541, 254Mo nokunye. |

| Insimbi ye-Carbon:I-A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 njll. | |

| I-Duplex insimbi engagqwali:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 nokunye. | |

| Insimbi yepayipi:I-A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 njll. | |

| Ingxube ye-nickel:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 njll. | |

| Ingxubevange ye-Cr-Mo:I-A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, njll. | |

| Isicelo | Imboni ye-petrochemical;imboni yezindiza kanye ne-aerospace;imboni yezemithi;igesi ekhishwayo;imboni yamandla;isakhiwo semikhumbi;ukuhlanza amanzi,njll. |

| Izinzuzo | isitoko esilungile, isikhathi sokulethwa esisheshayo; sitholakala kuwo wonke amasayizi, enziwe ngokwezifiso; ikhwalithi ephezulu |

DIMENSION AMAZINGA

UMBONISO WEMINININGWANE YEMIKHIQIZO

1. Ubuso

Ingaphakanyiswa ubuso(RF), ubuso obugcwele(FF), Iring joint(RTJ) , Groove, Language, noma yenziwe ngendlela oyifisayo.

2.Socket weld

3.CNC inhlawulo iqediwe

Ukuqedwa kobuso: Ukuqedwa ebusweni be-flange kukalwa njenge-Arithmetical Average Roughness Height(AARH). Isiphetho sinqunywa yizinga elisetshenzisiwe. Isibonelo, i-ANSI B16.5 icacisa ukuqedwa kobuso ngaphakathi kobubanzi 125AARH-500AARH(3.2Ra ukuya ku-12.5Ra). Okunye ukuqedwa kuyatholakala ngesicelo, isibonelo 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra noma 6.3/12.5Ra. Ububanzi 3.2/6.3Ra buvame kakhulu.

UKUMAKA NOKUPAKA

• Ungqimba ngalunye sebenzisa ifilimu yepulasitiki ukuvikela indawo engaphezulu

• Ngokuba zonke insimbi engagqwali zigcwele plywood case. Ukuze usayizi omkhulu we-carbon flange upakishwe nge-plywood pallet. Noma kungenziwa ngokwezifiso ukupakisha.

• Uphawu lokuthumela lungenza ngesicelo

• Izimpawu emikhiqizweni zingaqoshwa noma ziphrintwe. I-OEM yamukelwe.

UKUHLOLA

• Ukuhlolwa kwe-UT

• Ukuhlolwa kwe-PT

• Ukuhlolwa kwe-MT

• Ukuhlolwa kobukhulu

Ngaphambi kokulethwa, ithimba lethu le-QC lizohlela ukuhlolwa kwe-NDT nokuhlolwa kobukhulu. Futhi yamukela i-TPI(ukuhlolwa komuntu wesithathu).

INQUBO YOKHIQIZA

| 1. Khetha impahla eluhlaza yangempela | 2. Sika impahla eluhlaza | 3. Ukushisa kwangaphambili |

| 4. Ukuqamba | 5. Ukwelashwa kokushisa | 6. Imishini Enzima |

| 7. Ukubhoboza | 8. Ukwenza kahle | 9. Ukumaka |

| 10. Ukuhlola | 11. Ukupakisha | 12. Ukulethwa |

FAQ

1. Iyini i-ANSI B16.5 eyenziwe ngensimbi engenasici ye-weld flange?

I-ANSI B16.5 Forged Stainless Steel Socket Weld Flange iyi-flange esetshenziselwa ukuhlanganisa amapayipi ekufakweni kwengcindezi ephezulu. Yenziwe ngensimbi engagqwali eyakhiwe ngokuxhunywa kwe-socket weld ukuze kufakwe kalula.

2. I-ANSI B16.5 yensimbi engagqwali enesokhethi ye-welld flange ihluke kanjani kwezinye izinhlobo ze-flange?

Ngokungafani nezinye izinhlobo ze-flange, i-ANSI B16.5 yensimbi engagqwali ye-socket weld flanges idinga uxhumano lwe-socket weld lapho ipayipi lifakwa khona ku-flange futhi lishiselwe ngaphakathi. Lokhu kunikeza ukuhlangana okuqinile nokungavuzi.

3. Yiziphi izinzuzo zokusebenzisa i-ANSI B16.5 yensimbi engagqwali eyenziwe ngamaflange weld weld?

Izinzuzo eziyinhloko zokusebenzisa i-ANSI B16.5 ama-flange e-stainless steel socket weld weld afaka amandla aphezulu, ukwethembeka kanye nokumelana nokugqwala okuhle kakhulu. Zilungele izinhlelo zokusebenza ezidinga amalunga aqinile, avikelekile.

4. Yiziphi izimboni ezivame ukusebenzisa i-ANSI B16.5 i-foged stainless steel socket flanges?

I-ANSI B16.5 i-stainless steel socket weld flanges eyi-forged ivame ukusetshenziswa ezimbonini zikawoyela negesi, i-petrochemical, amakhemikhali, ukukhiqiza amandla kanye nezimboni zokuhlanza amanzi. Zifanele ukucindezela okuphezulu kanye nezicelo zokushisa okuphezulu.

5. Ingabe i-ANSI B16.5 ingasetshenziswa ama-flange e-stainless steel socket weld flange ekusetshenzisweni kwegesi noketshezi?

Yebo, amaflange e-ANSI B16.5 enziwe ngensimbi engenasici ayatholakala ukuze asetshenziswe igesi noketshezi. Zenzelwe ukuhlinzeka ngoxhumano oluvikelekile futhi zingamelana nengcindezi nezimfuneko zokushisa zohlu olubanzi loketshezi.

6. Yiziphi izindinganiso ezilandelwayo ukuze kwenziwe ama-flange weld weld steel stainless steel socket we-ANSI B16.5?

I-ANSI B16.5 Forged Stainless Steel Socket Weld Flanges akhiqizwa ngamazinga asungulwe yi-American National Standards Institute (ANSI). Lawa mazinga aqinisekisa ukuthi ama-flange ahlangabezana nezidingo ezidingekayo zekhwalithi nokusebenza.

7. Ingabe i-ANSI B16.5 yensimbi engagqwali enesokhethi flange yokushisela iyatholakala ngosayizi abahlukene kanye nezilinganiso zokucindezela?

Yebo, amaflange e-ANSI B16.5 enziwe ngensimbi engenasici atholakala ngobukhulu obuhlukahlukene nezilinganiso zokucindezela. Lokhu kuvumela ukuguquguquka nokuhambisana nezinhlelo zamapayipi ahlukene kanye nezidingo.

8. Ingabe i-ANSI B16.5 ingasetshenziselwa ama-flange e-weld steel stainless steel socket flanges ekuxhumekeni kwendawo ephakanyisiwe neyisicaba?

Yebo, amaflange e-ANSI B16.5 enziwe ngensimbi engenasici ayatholakala kukho kokubili ukuxhumana okuphakanyisiwe kobuso nobuso obuyisicaba. Ubuso be-Flange bungenziwa ngokwezifiso ukuze buhlangabezane nezidingo ezithile zohlelo lokusebenza.

9. Ingabe i-ANSI B16.5 yensimbi engagqwali enesokhethi ye-weld flange ifanele ukusetshenziswa kwezinga lokushisa eliphezulu?

Yebo, amaflange e-ANSI B16.5 enziwe ngensimbi engenasici afanele ukusetshenziswa kokushisa okuphezulu. Zenzelwe ukumelana namazinga okushisa aphezulu ngaphandle kokuphazamisa ubuqotho bazo besakhiwo.

10. Kufanele afakwe kanjani ama-flange e-anSI B16.5 ensimbi engenasici?

I-ANSI B16.5 Ama-flange e-Forged stainless steel socket weld azofakwa ngendlela yokuthi ipayipi lifakwe endaweni yokushisela isokhethi bese lishiselwa ngaphakathi. Kubalulekile ukuqinisekisa ukuthi i-welding efanele ifinyelelwa ukuze kugcinwe amandla nobuqotho bokuxhumana.

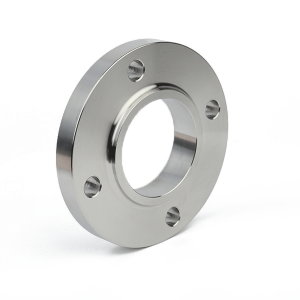

Imininingwane yemikhiqizo iyakhombisa

1. Ubuso

Ingaphakanyiswa ubuso(RF), ubuso obugcwele(FF), Iring joint(RTJ) , Groove, Language, noma yenziwe ngendlela oyifisayo.

2.Socket weld

3.CNC inhlawulo iqediwe

Ukuqedwa kobuso: Ukuqedwa ebusweni be-flange kukalwa njenge-Arithmetical Average Roughness Height(AARH). Isiphetho sinqunywa yizinga elisetshenzisiwe. Isibonelo, i-ANSI B16.5 icacisa ukuqedwa kobuso ngaphakathi kobubanzi 125AARH-500AARH(3.2Ra ukuya ku-12.5Ra). Okunye ukuqedwa kuyatholakala ngesicelo, isibonelo 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra noma 6.3/12.5Ra. Ububanzi 3.2/6.3Ra buvame kakhulu.

Ukumaka Nokupakisha

• Ungqimba ngalunye sebenzisa ifilimu yepulasitiki ukuvikela indawo engaphezulu

• Ngokuba zonke insimbi engagqwali zigcwele plywood case. Ukuze usayizi omkhulu we-carbon flange upakishwe nge-plywood pallet. Noma kungenziwa ngokwezifiso ukupakisha.

• Uphawu lokuthumela lungenza ngesicelo

• Izimpawu emikhiqizweni zingaqoshwa noma ziphrintwe. I-OEM yamukelwe.

Ukuhlola

• Ukuhlolwa kwe-UT

• Ukuhlolwa kwe-PT

• Ukuhlolwa kwe-MT

• Ukuhlolwa kobukhulu

Ngaphambi kokulethwa, ithimba lethu le-QC lizohlela ukuhlolwa kwe-NDT nokuhlolwa kobukhulu. Futhi yamukela i-TPI(ukuhlolwa komuntu wesithathu).

Inqubo yokukhiqiza

| 1. Khetha impahla eluhlaza yangempela | 2. Sika impahla eluhlaza | 3. Ukushisa kwangaphambili |

| 4. Ukuqamba | 5. Ukwelashwa kokushisa | 6. Imishini Enzima |

| 7. Ukubhoboza | 8. Ukwenza kahle | 9. Ukumaka |

| 10. Ukuhlola | 11. Ukupakisha | 12. Ukulethwa |

-

I-ASME B16.5 BL RF ASTM A182 F316L Insimbi engagqwali...

-

Ngokwezifiso Ishidi Leshubhu Elingajwayelekile Ibala le-Flange...

-

kwakhiwa i-asme b16.36 wn orifice flange noJack ...

-

I-AMSE B16.5 A105 eyenziwe nge-carbon steel weld neck f...

-

I-ASTM A182 F51 F53 BL ANSI B16.5 Insimbi engagqwali...

-

I-ANSI DIN Forged Class150 Stainless Steel Slip o...