ISICELO

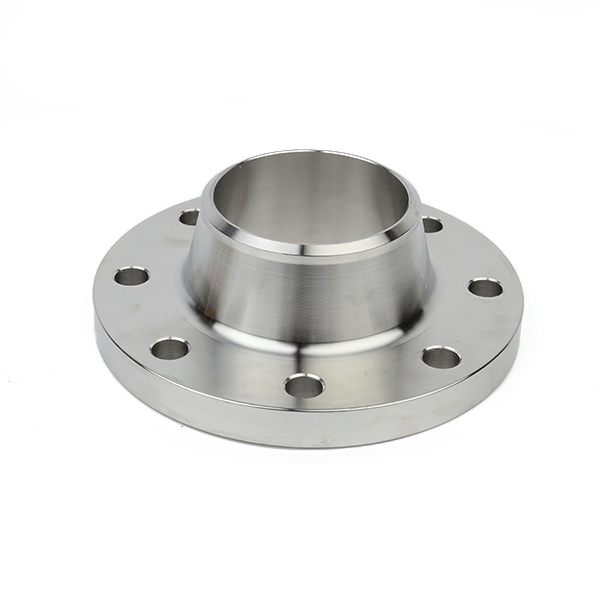

| Igama Lomkhiqizo | I-Lap joint/i-flange ekhululekile |

| Usayizi | 1/2"-24" |

| Ingcindezi | 150#-2500#,PN0.6-PN400,5K-40K |

| Okujwayelekile | I-ANSI B16.5, EN1092-1, JIS B2220 njll. |

| Isiphetho se-stub | I-MSS SP 43, i-ASME B16.9 |

| Izinto | Insimbi engagqwali:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo njalo njalo. |

| Insimbi yekhabhoni:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 njll. | |

| Insimbi engagqwali ephindwe kabili:I-UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 njll. | |

| Insimbi yepayipi:I-A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 njll. | |

| Ingxubevange ye-nickel:i-inconel600, i-inconel625, i-inconel690, i-incoloy800, i-incoloy 825, i-incoloy 800H,C22, C-276, i-Monel400, i-Alloy20 njll. | |

| Ingxubevange ye-Cr-Mo:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, njll. | |

| Isicelo | Imboni ye-Petrochemical; imboni yezindiza kanye nezindiza; imboni yemithi; ukukhishwa kwegesi; isitshalo samandla; isakhiwo semikhumbi; ukwelashwa kwamanzi, njll. |

| Izinzuzo | isitoko esilungile, isikhathi sokulethwa esisheshayo; sitholakala ngosayizi bonke, senziwe ngokwezifiso; ikhwalithi ephezulu |

AMAZINGA OKUDINGEKA

UMBONO WEMINININGWANE YEMIKHIQIZO

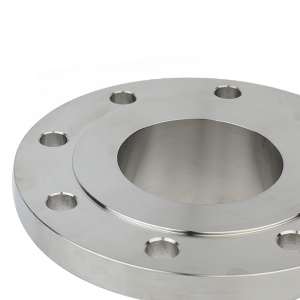

1. Ubuso

Kungaba ubuso obuphakanyisiwe (RF), ubuso obugcwele (FF), i-Ring joint (RTJ), i-Groove, ulimi, noma kwenziwe ngokwezifiso.

2. Ukuphela kwe-Bevel ngokwe-ANSI B16.25

3. I-CNC fine iqediwe.

Ukuphela kobuso: Ukuphela kobuso be-flange kulinganiswa njengokuphakama kwesilinganiso sobunzima be-Arithmetical (AARH). Ukuphela kunqunywa ngokwezinga elisetshenzisiwe. Isibonelo, i-ANSI B16.5 icacisa ukuqeda kobuso ngaphakathi kwebanga elingu-125AARH-500AARH (3.2Ra kuya ku-12.5Ra). Okunye ukuqeda kuyatholakala uma kufunwa, isibonelo u-1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra noma u-6.3/12.5Ra. Ububanzi obungu-3.2/6.3Ra buvame kakhulu.

UKUMAKISHA NOKUPHAKISHA

• Isendlalelo ngasinye sisebenzisa ifilimu yepulasitiki ukuvikela indawo engaphezulu

• Kuzo zonke izinsimbi ezingagqwali zipakishwa nge-plywood case. Ukuze kube ne-carbon flange enkulu zipakishwa nge-plywood pallet. Noma zingapakishwa ngendlela oyifisayo.

• Uphawu lokuthumela lungenza uma luceliwe

• Izimpawu emikhiqizweni zingabazwa noma ziphrintwe. I-OEM iyamukelwa.

UKUHLOLA

• Ukuhlolwa kwe-UT

• Ukuhlolwa kwe-PT

• Ukuhlolwa kwe-MT

• Ukuhlolwa kobukhulu

Ngaphambi kokulethwa, ithimba lethu le-QC lizohlela ukuhlolwa kwe-NDT kanye nokuhlolwa kobukhulu. Futhi lamukela i-TPI (ukuhlolwa komuntu wesithathu).

INKQUBO YOKUKHIQIZWA

| 1. Khetha izinto zokusetshenziswa zangempela | 2. Sika izinto zokusetshenziswa | 3. Ukushisa kusengaphambili |

| 4. Ukwakha | 5. Ukwelashwa ngokushisa | 6. Umshini Onzima |

| 7. Ukubhoboza | 8. Ukubumba kahle | 9. Ukumaka |

| 10. Ukuhlolwa | 11. Ukupakisha | 12. Ukulethwa |

ICALA LOKUBAMBISANA

Iphrojekthi eseTurkey, ama-flange asetshenziswa emipayipini yegesi yemvelo. Wonke lawo ma-flange avunyelwe yi-TUV.

ISHIDI LEDATHA LE-FLANGE

1Ubukhulu be-flange kanye nokubekezelelana kufanele kube ngokwe-ASME B16.5.

2. Ama-Flanges kufanele akhiqizwe ngokubumba.

3. Izinto zokwakha kufanele zihambisane nezindinganiso ze-ASTM A105, ASTM A694 F65 kanye ne-ASTM A694 F70.

4. Ama-flange e-ASTM A694 F65 kanye ne-ASTM A694 F70 kufanele acinywe futhi aqiniswe.

5. Izitifiketi zokuhlolwa kwezinto kanye nemibiko yokwelashwa kokushisa kufanele zenziwe zitholakale ukuze kuhlolwe i-TPI.

6. Ama-flange e-WN kumele abe neziphetho ze-bevel ezihambisana ne-ASME B16.25.

7. Amanani okuhlola amakhemikhali kanye nokwemishini (umthelela, isivuno, ukuqina njll.) kumele ahambisane namazinga ahlobene.

8. Zonke izindawo kufanele zifakwe umshini futhi zifakwe i-varnish ngamafutha acacile ukuze kuvinjelwe ukugqwala.

9. Ukumaka kuzofaka ulwazi olulandelayo,

• Ububanzi (isikhathi esiphelelwe yisikhathi esingu-6”)

• Isigaba sokucindezela (siphelelwa yisikhathi ngama-150 LB)

• Izinga Lezinto (iphelelwa yisikhathi i-ASTM A 105)

• Ubukhulu bodonga (isikhathi esingaphezu kuka-4,78 mm)

• Inombolo Yokushisa (iphelelwa yisikhathi ngo-138413)

• Izinga lokukhiqiza (i-ASME B16.5)

10. Izinto zokwakha kumele zingabi namaphutha noma imifantu ebusweni. Ukulungiswa kokushisela akuvunyelwe ngokuphelele.

11. Zonke izingcezu ze-flange kufanele zibe nobuso obuphakanyisiwe (RF) obunobuso bokuvala. Ubuso bokuvala kufanele bube yi-Ra 3,2 – 6,3 µm (125 – 250 mic. inc.) acc. ku-ASME B46.1.

12. Izinto kufanele zipakishwe ukuze kuvinjelwe umonakalo emishinini nasekuvaleni izindawo.

13. Zonke izilinganiso kufanele zibe ngezilinganiselo ezinhle (+). Izilinganiselo zokususa azivunyelwe ngokuphelele.

14. Izibani ze-Flange kufanele zihlanganiswe ne-ASME B16.25.

15. Inqubo yokukhiqiza izohlolwa nganoma yisiphi isikhathi yi-TPI.

16. I-TPI ingathatha amasampula kunoma iyiphi into yokwenza isampula yokuhlola yamakhemikhali/yemishini.

17. Umbiko wokuhlola ozayo uzobuyekezwa yi-TPI.

| Into | Usayizi (Inch) | Isigaba Sokucindezela | CS | Izinto | Isisindo (mm) | Indawo | Ubuningi. |

| I-SORF | 12 | 150LB | 20 | A105 | - | Ama-flange ethangi | 48 |

| I-SORF | 8 | 150LB | 20 | A105 | - | Ama-flange ethangi | 32 |

| I-SORF | 3 | 150LB | 20 | A105 | - | Ama-flange ethangi | 32 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 150LB | 20 | A105 | 14 | Ama-flange ethangi | 2 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 150LB | 20 | A105 | 5.54 | Ama-flange ethangi | 4 |

| I-SORF | 20 | 150LB | 20 | A105 | - | Ama-flange ethangi | 6 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 150LB | 20 | A105 | 5.54 | Ama-flange ethangi | 8 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 150LB | 20 | A105 | 14 | Ama-flange ethangi | 8 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 150LB | 20 | A105 | 16 | Ama-flange ethangi | 8 |

| I-SORF | 3 | 150LB | 20 | A105 | - | Ama-flange ethangi | 24 |

| I-SORF | 20 | 150LB | 20 | A105 | - | Ama-flange ethangi | 6 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 150LB | 20 | A105 | 5.54 | Ama-flange ethangi | 8 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 150LB | 20 | A105 | 14 | Ama-flange ethangi | 16 |

| Into | Usayizi (Inch) | Isigaba Sokucindezela | CS | Izinto | Isisindo (mm) | Indawo | Ubuningi. |

| I-Flange, Intamo Ehlanganisiwe | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 2 |

| I-Flange, Intamo Ehlanganisiwe | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | I-PSM1 | 6 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 4 |

| I-Flange, Intamo Ehlanganisiwe | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | I-PSM1 | 10 |

| I-Flange, Intamo Ehlanganisiwe | 12 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 4 |

| I-Flange, Intamo Ehlanganisiwe | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 4 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 25 |

| I-Flange, Intamo Ehlanganisiwe | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 16 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 2 |

| I-Flange, Intamo Ehlanganisiwe | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | I-PSM1 | 6 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 4 |

| I-Flange, Intamo Ehlanganisiwe | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | I-PSM1 | 10 |

| I-Flange, Intamo Ehlanganisiwe | 12 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 4 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 25 |

| I-Flange, Intamo Ehlanganisiwe | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 16 |

| I-Flange, Intamo Ehlanganisiwe | 10 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | I-PSB1 | 2 |

| I-Flange, Intamo Ehlanganisiwe | 6 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 4 |

| I-Flange, Intamo Ehlanganisiwe | 4 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 4 |

| I-Flange, Intamo Ehlanganisiwe | 18 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 2 |

| I-Flange, Intamo Ehlanganisiwe | 8 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 2 |

| I-Flange, Intamo Ehlanganisiwe | 8 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 2 |

Imibuzo Evame Ukubuzwa

1. Yiziphi izinhlobo ezahlukene zokufakwa kwamapayipi ensimbi engagqwali?

Impendulo: Izinto zokufaka amapayipi ensimbi engagqwali zifaka phakathi izinto zokufaka amapayipi okushisela izinqe, izinto zokufaka amapayipi okushisela amasokhethi, izinto zokufaka amapayipi anezintambo, ama-flange, ama-valve nezinye izinhlobo.

2. Uyini umehluko phakathi kokufakwa kwamapayipi ensimbi engagqwali angu-304 kanye no-316?

A: Insimbi engagqwali engu-304 ifaneleka kakhulu ezisetshenziswayo futhi inokumelana okuhle kakhulu nokugqwala. Insimbi engagqwali engu-316, ngakolunye uhlangothi, inokumelana kangcono nokugqwala ezindaweni ezigqwala kakhulu futhi ifaneleka kangcono ezisetshenziswa zasolwandle nezamakhemikhali.

3. Yiziphi izinzuzo zokusebenzisa izixhumi zepayipi ezihlanganisiwe ezihlanganisiwe?

A: Ukufakwa kwe-weld okuhlanganisiwe kunikeza amandla athuthukisiwe, ukuthembeka, kanye nokuxhumeka okungenawo amanzi. Kunikeza ukumelana okuhle kakhulu komthelela futhi kuyathandwa uma kusetshenziswa umfutho ophezulu kanye nokushisa okuphezulu.

4. Iyini i-flange yokushisela izinqe?

Impendulo: I-flange yokushisela izinqe iyi-flange yepayipi ene-hub ende enciphile futhi ehlanganiswe nepayipi. Ihlinzeka ngokushintsha okubushelelezi kusuka epayipini kuya e-flange ngamandla amakhulu nobuqotho.

5. Yiliphi izinga lensimbi engagqwali elivame ukusetshenziswa ekufakweni kwamapayipi?

A: Amagreyidi ensimbi engagqwali angu-304, 316, 304L, 316L kanye no-317 avame ukusetshenziswa ekufakweni kwamapayipi ngenxa yokumelana kwawo okuhle kakhulu nokugqwala, ukuqina kanye nokuguquguquka.

6. Ingabe izithako zamapayipi ensimbi engagqwali zingasetshenziswa ezisetshenziswa ekushiseni okuphezulu?

Impendulo: Yebo, ukufakwa kwensimbi engagqwali kufanelekela ukusetshenziswa kwezinga lokushisa eliphezulu. Kodwa-ke, izinga lensimbi engagqwali esetshenziswayo kufanele likhethwe ngokucophelela ngokusekelwe ezidingweni ezithile zokushisa zesicelo.

7. Ingabe izithako zamapayipi ensimbi engagqwali zifanelekile embonini yokudla neziphuzo?

Impendulo: Yebo, izixhumi zamapayipi ensimbi engagqwali zisetshenziswa kabanzi embonini yokudla neziphuzo ngenxa yokuhlanzeka kwazo, ukumelana nokugqwala, kanye nokugcinwa okulula.

8. Uyini umehluko phakathi kokufakwa kwe-socket welding kanye nokufakwa kwe-butt welding?

Impendulo: Ukufakwa kwamapayipi ahlanganisiwe ngesokhethi kufaka ipayipi kusokhethi bese kwenziwa ukushisela ifillet ukuxhuma ipayipi. Ukufakwa kwamapayipi e-Butt weld, ngakolunye uhlangothi, kudinga ukuthi iziphetho zepayipi zigoqwe bese zishintshwa.

9. Ingabe izinto zokufaka amapayipi ensimbi engagqwali zingaphinde zisetshenziswe?

A: Yebo, ukufakwa kwamapayipi ensimbi engagqwali kungasetshenziswa kabusha kakhulu. Insimbi engagqwali iyinto ehlala isikhathi eside engaphinde isetshenziswe futhi isetshenziswe kabusha ngaphandle kokulahlekelwa yizimfanelo zayo noma ikhwalithi.

10. Yiziphi izinzuzo zokusebenzisa izihlanganisi zamapayipi ensimbi engagqwali uma kuqhathaniswa nezinye izinto?

A: Ukufakwa kwamapayipi ensimbi engagqwali kunikeza izinzuzo eziningi, njengokumelana nokugqwala okuhle kakhulu, amandla aphezulu, ukuqina kanye nezakhiwo zokuhlanzeka. Azinakekelwa kahle, zihlala isikhathi eside futhi zibukeka zihlanzekile futhi zinhle.

UMBONO WEMINININGWANE YEMIKHIQIZO

1. Ubuso

Kungaba ubuso obuphakanyisiwe (RF), ubuso obugcwele (FF), i-Ring joint (RTJ), i-Groove, ulimi, noma kwenziwe ngokwezifiso.

2. Ukuphela kwe-Bevel ngokwe-ANSI B16.25

3. I-CNC fine iqediwe.

Ukuphela kobuso: Ukuphela kobuso be-flange kulinganiswa njengokuphakama kwesilinganiso sobunzima be-Arithmetical (AARH). Ukuphela kunqunywa ngokwezinga elisetshenzisiwe. Isibonelo, i-ANSI B16.5 icacisa ukuqeda kobuso ngaphakathi kwebanga elingu-125AARH-500AARH (3.2Ra kuya ku-12.5Ra). Okunye ukuqeda kuyatholakala uma kufunwa, isibonelo u-1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra noma u-6.3/12.5Ra. Ububanzi obungu-3.2/6.3Ra buvame kakhulu.

UKUMAKISHA NOKUPHAKISHA

• Isendlalelo ngasinye sisebenzisa ifilimu yepulasitiki ukuvikela indawo engaphezulu

• Kuzo zonke izinsimbi ezingagqwali zipakishwa nge-plywood case. Ukuze kube ne-carbon flange enkulu zipakishwa nge-plywood pallet. Noma zingapakishwa ngendlela oyifisayo.

• Uphawu lokuthumela lungenza uma luceliwe

• Izimpawu emikhiqizweni zingabazwa noma ziphrintwe. I-OEM iyamukelwa.

UKUHLOLA

• Ukuhlolwa kwe-UT

• Ukuhlolwa kwe-PT

• Ukuhlolwa kwe-MT

• Ukuhlolwa kobukhulu

Ngaphambi kokulethwa, ithimba lethu le-QC lizohlela ukuhlolwa kwe-NDT kanye nokuhlolwa kobukhulu. Futhi lamukela i-TPI (ukuhlolwa komuntu wesithathu).

INKQUBO YOKUKHIQIZWA

| 1. Khetha izinto zokusetshenziswa zangempela | 2. Sika izinto zokusetshenziswa | 3. Ukushisa kusengaphambili |

| 4. Ukwakha | 5. Ukwelashwa ngokushisa | 6. Umshini Onzima |

| 7. Ukubhoboza | 8. Ukubumba kahle | 9. Ukumaka |

| 10. Ukuhlolwa | 11. Ukupakisha | 12. Ukulethwa |

ICALA LOKUBAMBISANA

Iphrojekthi eseTurkey, ama-flange asetshenziswa emipayipini yegesi yemvelo. Wonke lawo ma-flange avunyelwe yi-TUV.

ISHIDI LEDATHA LE-FLANGE

1. Ubukhulu be-flange kanye nokubekezelelana kufanele kube ngokwe-ASME B16.5.

2. Ama-Flanges kufanele akhiqizwe ngokubumba.

3. Izinto zokwakha kufanele zihambisane nezindinganiso ze-ASTM A105, ASTM A694 F65 kanye ne-ASTM A694 F70.

4. Ama-flange e-ASTM A694 F65 kanye ne-ASTM A694 F70 kufanele acinywe futhi aqiniswe.

5. Izitifiketi zokuhlolwa kwezinto kanye nemibiko yokwelashwa kokushisa kufanele zenziwe zitholakale ukuze kuhlolwe i-TPI.

6. Ama-flange e-WN kumele abe neziphetho ze-bevel ezihambisana ne-ASME B16.25.

7. Amanani okuhlola amakhemikhali kanye nokwemishini (umthelela, isivuno, ukuqina njll.) kumele ahambisane namazinga ahlobene.

8. Zonke izindawo kufanele zifakwe umshini futhi zifakwe i-varnish ngamafutha acacile ukuze kuvinjelwe ukugqwala.

9. Ukumaka kuzofaka ulwazi olulandelayo,

• Ububanzi (isikhathi esiphelelwe yisikhathi esingu-6”)

• Isigaba sokucindezela (siphelelwa yisikhathi ngama-150 LB)

• Izinga Lezinto (iphelelwa yisikhathi i-ASTM A 105)

• Ubukhulu bodonga (isikhathi esingaphezu kuka-4,78 mm)

• Inombolo Yokushisa (iphelelwa yisikhathi ngo-138413)

• Izinga lokukhiqiza (i-ASME B16.5)

10. Izinto zokwakha kumele zingabi namaphutha noma imifantu ebusweni. Ukulungiswa kokushisela akuvunyelwe ngokuphelele.

11. Zonke izingcezu ze-flange kufanele zibe nobuso obuphakanyisiwe (RF) obunobuso bokuvala. Ubuso bokuvala kufanele bube yi-Ra 3,2 – 6,3 µm (125 – 250 mic. inc.) acc. ku-ASME B46.1.

12. Izinto kufanele zipakishwe ukuze kuvinjelwe umonakalo emishinini nasekuvaleni izindawo.

13. Zonke izilinganiso kufanele zibe ngezilinganiselo ezinhle (+). Izilinganiselo zokususa azivunyelwe ngokuphelele.

14. Izibani ze-Flange kufanele zihlanganiswe ne-ASME B16.25.

15. Inqubo yokukhiqiza izohlolwa nganoma yisiphi isikhathi yi-TPI.

16. I-TPI ingathatha amasampula kunoma iyiphi into yokwenza isampula yokuhlola yamakhemikhali/yemishini.

17. Umbiko wokuhlola ozayo uzobuyekezwa yi-TPI.

| Into | Usayizi (Inch) | Isigaba Sokucindezela | CS | Izinto | Isisindo (mm) | Indawo | Ubuningi. |

| I-SORF | 12 | 150LB | 20 | A105 | - | Ama-flange ethangi | 48 |

| I-SORF | 8 | 150LB | 20 | A105 | - | Ama-flange ethangi | 32 |

| I-SORF | 3 | 150LB | 20 | A105 | - | Ama-flange ethangi | 32 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 150LB | 20 | A105 | 14 | Ama-flange ethangi | 2 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 150LB | 20 | A105 | 5.54 | Ama-flange ethangi | 4 |

| I-SORF | 20 | 150LB | 20 | A105 | - | Ama-flange ethangi | 6 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 150LB | 20 | A105 | 5.54 | Ama-flange ethangi | 8 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 150LB | 20 | A105 | 14 | Ama-flange ethangi | 8 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 150LB | 20 | A105 | 16 | Ama-flange ethangi | 8 |

| I-SORF | 3 | 150LB | 20 | A105 | - | Ama-flange ethangi | 24 |

| I-SORF | 20 | 150LB | 20 | A105 | - | Ama-flange ethangi | 6 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 150LB | 20 | A105 | 5.54 | Ama-flange ethangi | 8 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 150LB | 20 | A105 | 14 | Ama-flange ethangi | 16 |

| Into | Usayizi (Inch) | Isigaba Sokucindezela | CS | Izinto | Isisindo (mm) | Indawo | Ubuningi. |

| I-Flange, Intamo Ehlanganisiwe | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 2 |

| I-Flange, Intamo Ehlanganisiwe | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | I-PSM1 | 6 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 4 |

| I-Flange, Intamo Ehlanganisiwe | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | I-PSM1 | 10 |

| I-Flange, Intamo Ehlanganisiwe | 12 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 4 |

| I-Flange, Intamo Ehlanganisiwe | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 4 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 25 |

| I-Flange, Intamo Ehlanganisiwe | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 16 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 2 |

| I-Flange, Intamo Ehlanganisiwe | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | I-PSM1 | 6 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 4 |

| I-Flange, Intamo Ehlanganisiwe | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | I-PSM1 | 10 |

| I-Flange, Intamo Ehlanganisiwe | 12 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 4 |

| I-Flange, Intamo Ehlanganisiwe | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 25 |

| I-Flange, Intamo Ehlanganisiwe | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 16 |

| I-Flange, Intamo Ehlanganisiwe | 10 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | I-PSB1 | 2 |

| I-Flange, Intamo Ehlanganisiwe | 6 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 4 |

| I-Flange, Intamo Ehlanganisiwe | 4 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 4 |

| I-Flange, Intamo Ehlanganisiwe | 18 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 2 |

| I-Flange, Intamo Ehlanganisiwe | 8 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 2 |

| I-Flange, Intamo Ehlanganisiwe | 8 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 2 |

Ukufakwa kwamapayipi kuyizinto ezibalulekile ohlelweni lwamapayipi, ezisetshenziselwa ukuxhuma, ukuqondisa kabusha, ukuphambukisa, ukushintsha usayizi, ukuvala noma ukulawula ukugeleza koketshezi. Zisetshenziswa kabanzi emikhakheni efana nokwakha, imboni, amandla kanye nezinsizakalo zikamasipala.

Imisebenzi Eyinhloko:Ingenza imisebenzi efana nokuxhuma amapayipi, ukushintsha indlela yokugeleza, ukuhlukanisa nokuhlanganisa ukugeleza, ukulungisa ububanzi bamapayipi, ukuvala amapayipi, ukulawula nokulawula.

Ububanzi Bokusetshenziswa:

- Ukwakhiwa kwamanzi kanye nokukhipha amanzi:Izindololwane ze-PVC kanye ne-PPR tris zisetshenziselwa amanethiwekhi amapayipi amanzi.

- Amapayipi ezimboni:Ama-flange ensimbi engagqwali kanye nezindololwane zensimbi ezixutshwe ngomlotha zisetshenziselwa ukuthutha izinto zamakhemikhali.

- Ukuthuthwa kwamandla:Izithako zamapayipi ensimbi anomfutho ophezulu zisetshenziswa emapayipini kawoyela negesi.

- I-HVAC (Ukushisa, Umoya Ongenisayo, kanye Nomoya Ongenisayo):Izithako zamapayipi ethusi zisetshenziselwa ukuxhuma amapayipi efriji, kanti amalunga aguquguqukayo asetshenziselwa ukunciphisa ukudlidliza.

- Ukunisela ngenkasa kwezolimo:Izixhumi ezisheshayo zenza kube lula ukuhlanganiswa nokuhlukaniswa kwezinhlelo zokunisela ezifafaza.

-

Ukufakwa Kwepayipi A105 Class 150 Ss Carbon Steel Pl ...

-

I-Stainle Ehlanganisiwe Ye-Orifice Ejwayelekile Yokucindezela ...

-

uhlobo lwentamo yensimbi yekhabhoni engu-6″ ANSI CLASS ...

-

i-carbon steel a105 forge blind flange

-

I-ASTM A182 F51 F53 BL ANSI B16.5 Insimbi engagqwali...

-

i-flange ye-orifice WN 4″ 900# RF A105 dual gr ...