INKCAZO

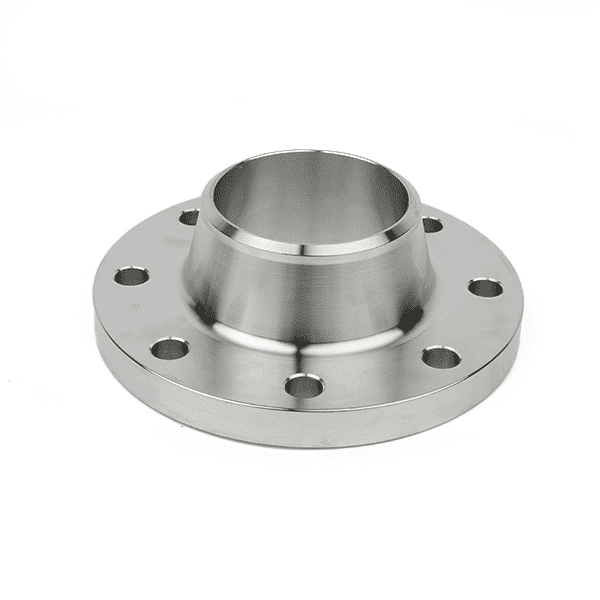

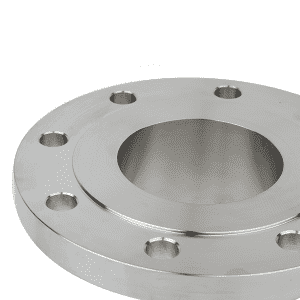

| Igama Lomkhiqizo | I-Lap joint/I-flange exegayo |

| Usayizi | 1/2"-24" |

| Ingcindezi | 150#-2500#,PN0.6-PN400,5K-40K |

| Okujwayelekile | I-ANSI B16.5, EN1092-1, JIS B2220 njll. |

| Isiphetho se-stub | I-MSS SP 43, ASME B16.9 |

| Okubalulekile | Insimbi engagqwali:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1, 501, 414. 54Mo nokunye. |

| Insimbi ye-Carbon:I-A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 njll. | |

| I-Duplex insimbi engagqwali:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 nokunye. | |

| Insimbi yepayipi:I-A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 njll. | |

| I-nickel alloy:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 njll. | |

| Ingxubevange ye-Cr-Mo:I-A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, njll. | |

| Isicelo | Imboni ye-petrochemical;imboni yezindiza kanye ne-aerospace;imboni yezemithi;igesi ekhishwayo;imboni yamandla;isakhiwo semikhumbi;ukuhlanza amanzi,njll. |

| Izinzuzo | isitoko esilungile, isikhathi sokulethwa esisheshayo; sitholakala kuwo wonke amasayizi, enziwe ngokwezifiso; ikhwalithi ephezulu |

DIMENSION AMAZINGA

UMBONISO WEMINININGWANE YEMIKHIQIZO

1. Ubuso

Ingaphakanyiswa ubuso(RF), ubuso obugcwele(FF), Iring joint(RTJ) , Groove, Language, noma yenziwe ngendlela oyifisayo.

2.Bevel end njengokusho kwe-ANSI B16.25

3.CNC inhlawulo iqediwe.

Ukuqedwa kobuso: Ukuqedwa ebusweni be-flange kukalwa njenge-Arithmetical Average Roughness Height(AARH).Isiphetho sinqunywa yizinga elisetshenzisiwe.Isibonelo, i-ANSI B16.5 icacisa ukuqedwa kobuso ngaphakathi kobubanzi 125AARH-500AARH(3.2Ra ukuya ku-12.5Ra).Okunye ukuqedwa kuyatholakala ngesicelo, isibonelo 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra noma 6.3/12.5Ra.Ububanzi 3.2/6.3Ra buvame kakhulu.

UKUMAKA NOKUPAKA

• Ungqimba ngalunye sebenzisa ifilimu yepulasitiki ukuvikela indawo engaphezulu

• Ngokuba zonke insimbi engagqwali zigcwele plywood case.Ukuze usayizi omkhulu we-carbon flange upakishwe nge-plywood pallet.Noma kungenziwa ngezifiso ukupakisha.

• Uphawu lokuthumela lungenza ngesicelo

• Izimpawu emikhiqizweni zingaqoshwa noma ziphrintwe.I-OEM yamukelwe.

UKUHLOLA

• Ukuhlolwa kwe-UT

• Ukuhlolwa kwe-PT

• Ukuhlolwa kwe-MT

• Ukuhlolwa kobukhulu

Ngaphambi kokulethwa, ithimba lethu le-QC lizohlela ukuhlolwa kwe-NDT nokuhlolwa kobukhulu. Futhi yamukela i-TPI(ukuhlolwa komuntu wesithathu).

INQUBO YOKHIQIZA

| 1. Khetha impahla eluhlaza yangempela | 2. Sika impahla eluhlaza | 3. Ukushisa kwangaphambili |

| 4. Ukuqamba | 5. Ukwelashwa kokushisa | 6. Imishini Enzima |

| 7. Ukubhoboza | 8. Ukwenza kahle | 9. Ukumaka |

| 10. Ukuhlola | 11. Ukupakisha | 12. Ukulethwa |

ICALA LOKUBAMBISANA

Iphrojekthi eTurkey, ama-flange asetshenziswa kumapayipi egesi yemvelo.Wonke lawo ma-flange avunyelwe yi-TUV.

ISHIDI LEDATHA LE-FLANGE

1.Ubukhulu be-Flange nokubekezelelana kuzohambisana ne-ASME B16.5.

2. Ama-flanges azokhiqizwa ngokukhwabanisa.

3. Izinto ezisetshenziswayo kufanele zihambisane namazinga e-ASTM A105, ASTM A694 F65 kanye ne-ASTM A694 F70.

4. Amaflange e-ASTM A694 F65 kanye ne-ASTM A694 F70 azocishwa futhi afutheke.

5. Izitifiketi zokuhlolwa kwempahla kanye nemibiko yokwelashwa kokushisa izotholakala ukuze ihlolwe i-TPI.

6. Ama-WN flanges azoba ne-bevel ends acc.ku-ASME B16.25.

7. Amanani okuhlola amakhemikhali kanye nemishini (umthelela, isivuno, ukuqina njll.) azohambisana namazinga ahlobene.

8. Zonke izindawo ezingaphezulu kufanele zenziwe ngomshini futhi zivanishwe ngamafutha akhanyayo ukuze kugwenywe ukugqwala.

9. Ukumaka kuzofaka imininingwane elandelayo,

• Ububanzi (exp. 6”)

• Isigaba sokucindezela (exp. 150 LB)

• Ibanga Elibalulekile (exp. ASTM A 105)

• Ukujiya kwezindonga (exp. 4,78 mm)

• Inombolo Yokushisa (exp. 138413)

• Izinga lokukhiqiza (ASME B16.5)

10. Izinto ezisetshenziswayo ngeke zingabi nasici noma imifantu.Ukulungiswa kwe-welding kwenqatshelwe ngokuphelele.

11. Wonke ama-flange azophakanyiswa ubuso (RF) endaweni evalekayo.Indawo yokuvala izoba ngu-Ra 3,2 – 6,3 µm (125 – 250 mic. inc.) acc.ku-ASME B46.1.

12. Izinto ezisetshenziswayo kufanele zipakishwe ukuvimbela ukulimala komshini, kanye nezindawo zokuvala.

13. Zonke izilinganiso zizobekezelelwa kahle (+).Ukubekezelela okuncane kwenqatshelwe ngokuphelele.

14. Ama-flange bevellings azokwenziwa acc.ku-ASME B16.25.

15. Inqubo yokukhiqiza izobhekwa noma nini yi-TPI.

16. I-TPI ingathatha amasampula kunoma iyiphi into yesampula yokuhlola amakhemikhali/imishini.

17. Umbiko wokuhlola ongenayo uzobuyekezwa yi-TPI.

| Into | Usayizi (Intshi) | Ikilasi Lokucindezela | CS | Okubalulekile | I-WT (mm) | Indawo | Qty. |

| I-SORF | 12 | 150LB | 20 | A105 | - | I-TANK FLANGES | 48 |

| I-SORF | 8 | 150LB | 20 | A105 | - | I-TANK FLANGES | 32 |

| I-SORF | 3 | 150LB | 20 | A105 | - | I-TANK FLANGES | 32 |

| I-Flange, i-Weld Neck | 24 | 150LB | 20 | A105 | 14 | I-TANK FLANGES | 2 |

| I-Flange, i-Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | I-TANK FLANGES | 4 |

| I-SORF | 20 | 150LB | 20 | A105 | - | I-TANK FLANGES | 6 |

| I-Flange, i-Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | I-TANK FLANGES | 8 |

| I-Flange, i-Weld Neck | 24 | 150LB | 20 | A105 | 14 | I-TANK FLANGES | 8 |

| I-Flange, i-Weld Neck | 24 | 150LB | 20 | A105 | 16 | I-TANK FLANGES | 8 |

| I-SORF | 3 | 150LB | 20 | A105 | - | I-TANK FLANGES | 24 |

| I-SORF | 20 | 150LB | 20 | A105 | - | I-TANK FLANGES | 6 |

| I-Flange, i-Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | I-TANK FLANGES | 8 |

| I-Flange, i-Weld Neck | 24 | 150LB | 20 | A105 | 14 | I-TANK FLANGES | 16 |

| Into | Usayizi (Intshi) | Ikilasi Lokucindezela | CS | Okubalulekile | I-WT (mm) | Indawo | Qty. |

| I-Flange, i-Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 2 |

| I-Flange, i-Weld Neck | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | I-PSM1 | 6 |

| I-Flange, i-Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 4 |

| I-Flange, i-Weld Neck | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | I-PSM1 | 10 |

| I-Flange, i-Weld Neck | 12 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 4 |

| I-Flange, i-Weld Neck | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 4 |

| I-Flange, i-Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 25 |

| I-Flange, i-Weld Neck | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 16 |

| I-Flange, i-Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 2 |

| I-Flange, i-Weld Neck | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | I-PSM1 | 6 |

| I-Flange, i-Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 4 |

| I-Flange, i-Weld Neck | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | I-PSM1 | 10 |

| I-Flange, i-Weld Neck | 12 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 4 |

| I-Flange, i-Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 25 |

| I-Flange, i-Weld Neck | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 16 |

| I-Flange, i-Weld Neck | 10 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | I-PSB1 | 2 |

| I-Flange, i-Weld Neck | 6 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | I-RABIGH | 4 |

| I-Flange, i-Weld Neck | 4 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | I-RABIGH | 4 |

| I-Flange, i-Weld Neck | 18 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | I-RABIGH | 2 |

| I-Flange, i-Weld Neck | 8 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | I-RABIGH | 2 |

| I-Flange, i-Weld Neck | 8 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | I-RABIGH | 2 |

FAQ

1. Yiziphi izinhlobo ezahlukene zokufakwa kwamapayipi ensimbi engagqwali?

Impendulo: Ukufakwa kwepayipi lensimbi engagqwali kuhlanganisa ukufakwa kwepayipi le-butt welding, ukufakwa kwepayipi le-socket welding, ukufakwa kwamapayipi anentambo, ama-flange, ama-valve nezinye izinhlobo.

2. Uyini umehluko phakathi kokufakwa kwepayipi lensimbi engagqwali 304 no-316?

A: Insimbi engagqwali engu-304 ilungele ukusetshenziswa okuningi futhi inokumelana nokugqwala okuhle kakhulu.I-316 insimbi engagqwali, ngakolunye uhlangothi, inokumelana nokugqwala okungcono ezindaweni ezigqwala kakhulu futhi ifaneleka kangcono ukusetshenziswa olwandle namakhemikhali.

3. Yiziphi izinzuzo zokusebenzisa izixhumo zepayipi ezishiselwe izinqe ezifojiwe?

A: Ukufakwa kwe-butt weld okufojiwe kunikeza amandla athuthukisiwe, ukwethembeka, noxhumo olungavuzi.Banikeza ukumelana nomthelela omuhle kakhulu futhi bakhethwa ukucindezela okuphezulu kanye nezicelo zokushisa okuphezulu.

4. Iyini i-butt welding flange?

Impendulo: I-butt welding flange iyi-flange yepayipi enehabhu ende ene-tapered futhi eshiselwe epayipini.Inikeza ukuguquguquka okushelelayo kusuka epayipini kuya ku-flange ngamandla amakhulu nobuqotho.

5. Iliphi ibanga lensimbi engagqwali elivame ukusetshenziselwa ukufakwa kwamapayipi?

A: Insimbi engagqwali amamaki 304, 316, 304L, 316L kanye 317 avame ukusetshenziswa ukufakwa amapayipi ngenxa yokumelana nokugqwala kwabo okuhle kakhulu, ukuqina kanye nokuguquguquka.

6. Ingabe ukufakwa kwamapayipi ensimbi engagqwali kungasetshenziswa ekusetshenzisweni kokushisa okuphezulu?

Impendulo: Yebo, izinsimbi zensimbi ezingenasici zifanele izicelo zokushisa okuphezulu.Kodwa-ke, izinga lensimbi engagqwali elisetshenzisiwe kufanele likhethwe ngokucophelela ngokusekelwe ezidingweni ezithile zokushisa zesicelo.

7. Ingabe ukufakwa kwamapayipi ensimbi engagqwali kufanelekile embonini yokudla neziphuzo?

Impendulo: Yebo, ukufakwa kwamapayipi ensimbi engagqwali kusetshenziswa kabanzi embonini yokudla neziphuzo ngenxa yenhlanzeko, ukumelana nokugqwala, nokugcinwa kalula.

8. Uyini umehluko phakathi kokufakwa kwe-socket welding kanye nokufakwa kwe-butt welding?

Impendulo: Ukufakwa kwepayipi elihlanganisiwe le-socket faka ipayipi esokhethi bese wenza i-fillet welding ukuxhuma ipayipi.Ngakolunye uhlangothi, ukufakwa kwe-butt weld, kudinga ukuthi iziphetho zepayipi ziboshwe bese zishiselwa.

9. Ingabe ukufakwa kwamapayipi ensimbi engagqwali kungagaywa kabusha?

A: Yebo, ukufakwa kwamapayipi ensimbi engagqwali kungagaywa kabusha kakhulu.Insimbi engagqwali iyinto eqhubekayo engagaywa kabusha futhi isetshenziswe kabusha ngaphandle kokulahlekelwa izakhiwo zayo noma ikhwalithi.

10. Yiziphi izinzuzo zokusebenzisa ukufakwa kwamapayipi ensimbi engagqwali uma kuqhathaniswa nezinye izinto?

A: Ukufakwa kwamapayipi ensimbi engagqwali kunikeza izinzuzo eziningi, njengokumelana nokugqwala okuhle kakhulu, amandla aphezulu, ukuqina kanye nezindawo zokuhlanzeka.Zinokunakekelwa okuphansi, zinesikhathi eside sokuphila futhi zinokubukeka okuhlanzekile nokuhle.

UMBONISO WEMINININGWANE YEMIKHIQIZO

1. Ubuso

Ingaphakanyiswa ubuso(RF), ubuso obugcwele(FF), Iring joint(RTJ) , Groove, Language, noma yenziwe ngendlela oyifisayo.

2.Bevel end njengokusho kwe-ANSI B16.25

3.CNC inhlawulo iqediwe.

Ukuqedwa kobuso: Ukuqedwa ebusweni be-flange kukalwa njenge-Arithmetical Average Roughness Height(AARH).Isiphetho sinqunywa yizinga elisetshenzisiwe.Isibonelo, i-ANSI B16.5 icacisa ukuqedwa kobuso ngaphakathi kobubanzi 125AARH-500AARH(3.2Ra ukuya ku-12.5Ra).Okunye ukuqedwa kuyatholakala ngesicelo, isibonelo 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra noma 6.3/12.5Ra.Ububanzi 3.2/6.3Ra buvame kakhulu.

UKUMAKA NOKUPAKA

• Ungqimba ngalunye sebenzisa ifilimu yepulasitiki ukuvikela indawo engaphezulu

• Ngokuba zonke insimbi engagqwali zigcwele plywood case.Ukuze usayizi omkhulu we-carbon flange upakishwe nge-plywood pallet.Noma kungenziwa ngezifiso ukupakisha.

• Uphawu lokuthumela lungenza ngesicelo

• Izimpawu emikhiqizweni zingaqoshwa noma ziphrintwe.I-OEM yamukelwe.

UKUHLOLA

• Ukuhlolwa kwe-UT

• Ukuhlolwa kwe-PT

• Ukuhlolwa kwe-MT

• Ukuhlolwa kobukhulu

Ngaphambi kokulethwa, ithimba lethu le-QC lizohlela ukuhlolwa kwe-NDT nokuhlolwa kobukhulu. Futhi yamukela i-TPI(ukuhlolwa komuntu wesithathu).

INQUBO YOKHIQIZA

| 1. Khetha impahla eluhlaza yangempela | 2. Sika impahla eluhlaza | 3. Ukushisa kwangaphambili |

| 4. Ukuqamba | 5. Ukwelashwa kokushisa | 6. Imishini Enzima |

| 7. Ukubhoboza | 8. Ukwenza kahle | 9. Ukumaka |

| 10. Ukuhlola | 11. Ukupakisha | 12. Ukulethwa |

ICALA LOKUBAMBISANA

Iphrojekthi eTurkey, ama-flange asetshenziswa kumapayipi egesi yemvelo.Wonke lawo ma-flange avunyelwe yi-TUV.

ISHIDI LEDATHA LE-FLANGE

1. Ubukhulu be-Flange nokubekezelelana kuzohambisana ne-ASME B16.5.

2. Ama-flanges azokhiqizwa ngokukhwabanisa.

3. Izinto ezisetshenziswayo kufanele zihambisane namazinga e-ASTM A105, ASTM A694 F65 kanye ne-ASTM A694 F70.

4. Amaflange e-ASTM A694 F65 kanye ne-ASTM A694 F70 azocishwa futhi afutheke.

5. Izitifiketi zokuhlolwa kwempahla kanye nemibiko yokwelashwa kokushisa izotholakala ukuze ihlolwe i-TPI.

6. Ama-WN flanges azoba ne-bevel ends acc.ku-ASME B16.25.

7. Amanani okuhlola amakhemikhali kanye nemishini (umthelela, isivuno, ukuqina njll.) azohambisana namazinga ahlobene.

8. Zonke izindawo ezingaphezulu kufanele zenziwe ngomshini futhi zivanishwe ngamafutha akhanyayo ukuze kugwenywe ukugqwala.

9. Ukumaka kuzofaka imininingwane elandelayo,

• Ububanzi (exp. 6”)

• Isigaba sokucindezela (exp. 150 LB)

• Ibanga Elibalulekile (exp. ASTM A 105)

• Ukujiya kwezindonga (exp. 4,78 mm)

• Inombolo Yokushisa (exp. 138413)

• Izinga lokukhiqiza (ASME B16.5)

10. Izinto ezisetshenziswayo ngeke zingabi nasici noma imifantu.Ukulungiswa kwe-welding kwenqatshelwe ngokuphelele.

11. Wonke ama-flange azophakanyiswa ubuso (RF) endaweni evalekayo.Indawo yokuvala izoba ngu-Ra 3,2 – 6,3 µm (125 – 250 mic. inc.) acc.ku-ASME B46.1.

12. Izinto ezisetshenziswayo kufanele zipakishwe ukuvimbela ukulimala komshini, kanye nezindawo zokuvala.

13. Zonke izilinganiso zizobekezelelwa kahle (+).Ukubekezelela okuncane kwenqatshelwe ngokuphelele.

14. Ama-flange bevellings azokwenziwa acc.ku-ASME B16.25.

15. Inqubo yokukhiqiza izobhekwa noma nini yi-TPI.

16. I-TPI ingathatha amasampula kunoma iyiphi into yesampula yokuhlola amakhemikhali/imishini.

17. Umbiko wokuhlola ongenayo uzobuyekezwa yi-TPI.

| Into | Usayizi (Intshi) | Ikilasi Lokucindezela | CS | Okubalulekile | I-WT (mm) | Indawo | Qty. |

| I-SORF | 12 | 150LB | 20 | A105 | - | I-TANK FLANGES | 48 |

| I-SORF | 8 | 150LB | 20 | A105 | - | I-TANK FLANGES | 32 |

| I-SORF | 3 | 150LB | 20 | A105 | - | I-TANK FLANGES | 32 |

| I-Flange, i-Weld Neck | 24 | 150LB | 20 | A105 | 14 | I-TANK FLANGES | 2 |

| I-Flange, i-Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | I-TANK FLANGES | 4 |

| I-SORF | 20 | 150LB | 20 | A105 | - | I-TANK FLANGES | 6 |

| I-Flange, i-Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | I-TANK FLANGES | 8 |

| I-Flange, i-Weld Neck | 24 | 150LB | 20 | A105 | 14 | I-TANK FLANGES | 8 |

| I-Flange, i-Weld Neck | 24 | 150LB | 20 | A105 | 16 | I-TANK FLANGES | 8 |

| I-SORF | 3 | 150LB | 20 | A105 | - | I-TANK FLANGES | 24 |

| I-SORF | 20 | 150LB | 20 | A105 | - | I-TANK FLANGES | 6 |

| I-Flange, i-Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | I-TANK FLANGES | 8 |

| I-Flange, i-Weld Neck | 24 | 150LB | 20 | A105 | 14 | I-TANK FLANGES | 16 |

| Into | Usayizi (Intshi) | Ikilasi Lokucindezela | CS | Okubalulekile | I-WT (mm) | Indawo | Qty. |

| I-Flange, i-Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 2 |

| I-Flange, i-Weld Neck | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | I-PSM1 | 6 |

| I-Flange, i-Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 4 |

| I-Flange, i-Weld Neck | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | I-PSM1 | 10 |

| I-Flange, i-Weld Neck | 12 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 4 |

| I-Flange, i-Weld Neck | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 4 |

| I-Flange, i-Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 25 |

| I-Flange, i-Weld Neck | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 16 |

| I-Flange, i-Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 2 |

| I-Flange, i-Weld Neck | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | I-PSM1 | 6 |

| I-Flange, i-Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 4 |

| I-Flange, i-Weld Neck | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | I-PSM1 | 10 |

| I-Flange, i-Weld Neck | 12 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 4 |

| I-Flange, i-Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 25 |

| I-Flange, i-Weld Neck | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 16 |

| I-Flange, i-Weld Neck | 10 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | I-PSB1 | 2 |

| I-Flange, i-Weld Neck | 6 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | I-RABIGH | 4 |

| I-Flange, i-Weld Neck | 4 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | I-RABIGH | 4 |

| I-Flange, i-Weld Neck | 18 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | I-RABIGH | 2 |

| I-Flange, i-Weld Neck | 8 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | I-RABIGH | 2 |

| I-Flange, i-Weld Neck | 8 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | I-RABIGH | 2 |

-

Insimbi yokushisela i-flange yobuso obuphakanyisiwe EN1092-1 uhlobo0...

-

I-WN ANSI B16.36 orifice weld neck flange ene-ja...

-

Isokhethi weld flange A105 carbon steel SW RTJ 3/4...

-

Isikulufu BSP DIN PN 10/16 carbon steel A105 flange...

-

gwedla blank spacer A515 gr 60 umfanekiso 8 umbukwane...

-

ASME B16.48 CL150 CL300 Isigwedlo sepulangwe lepulangwe...