ISICELO

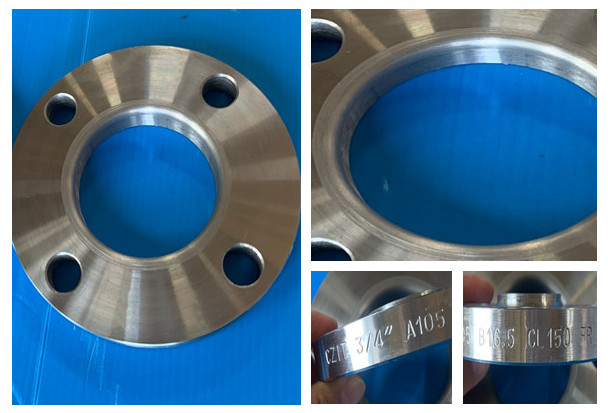

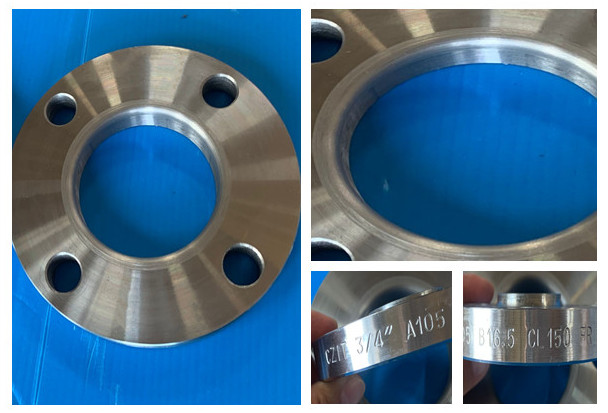

| Igama Lomkhiqizo | I-Lap joint/i-flange ekhululekile |

| Usayizi | 1/2"-24" |

| Ingcindezi | 150#-2500#,PN0.6-PN400,5K-40K |

| Okujwayelekile | I-ANSI B16.5, EN1092-1, JIS B2220 njll. |

| Isiphetho se-stub | I-MSS SP 43, i-ASME B16.9 |

| Izinto | Insimbi engagqwali:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo njalo njalo. |

| Insimbi yekhabhoni:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 njll. | |

| Insimbi engagqwali ephindwe kabili:I-UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 njll. | |

| Insimbi yepayipi:I-A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 njll. | |

| Ingxubevange ye-nickel:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 njll. | |

| Ingxubevange ye-Cr-Mo:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, njll. | |

| Isicelo | Imboni ye-Petrochemical; imboni yezindiza kanye nezindiza; imboni yemithi; ukukhishwa kwegesi; isitshalo samandla; isakhiwo semikhumbi; ukwelashwa kwamanzi, njll. |

| Izinzuzo | isitoko esilungile, isikhathi sokulethwa esisheshayo; sitholakala ngosayizi bonke, senziwe ngokwezifiso; ikhwalithi ephezulu |

AMAZINGA OKUDINGEKA

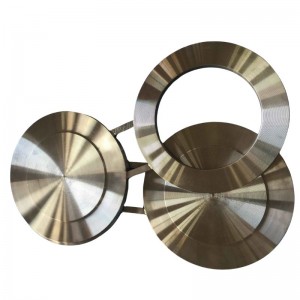

I-FLANGE EJWAYELEKILE YE-LAP

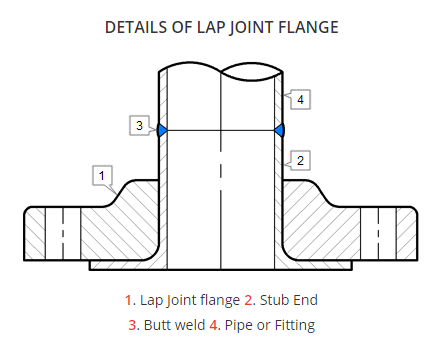

I-flange ehambisana ne-lap idinga izingxenye ezimbili zamapayipi ohlangothini ngalunye loxhumano oluhlanganisiwe, i-stub end kanye ne-backing flange ekhululekile. I-backing flange ekhululekile ifanelana nobubanzi bangaphandle be-stub end, ehlanganiswe ngezinqe nepayipi. I-backing flange ayihlanganisiwe nepayipi, futhi ingajikeleziswa, okuwusizo kakhulu lapho kudingeka ukuqondisa ama-flange ngesikhathi sokumiswa.

Futhi, njengoba i-backing flange ingathintani noketshezi lwenqubo, ingenziwa ngezinto ezingamelani nokugqwala kakhulu. Isibonelo, uma inqubo igqwala futhi idinga ukuthi ipayipi libe ngensimbi engagqwali, njengaku-ASTM A312 TP316L, khona-ke ukuphela kwe-stub kumele kwenziwe nge-SS 316L; noma kunjalo, i-backing flange ingenziwa nge-ASTM A105 eshibhile.

Le ndlela yokuxhumanisa ayiqinile njenge-flange yentamo ye-weld kodwa ingcono kunezixhumi ezifakwe izikulufo, i-socket weld, kanye ne-slip; nokho, kubiza kakhulu ukuyisebenzisa, ngoba idinga i-full-penetration butt weld futhi idinga izingxenye ezimbili.

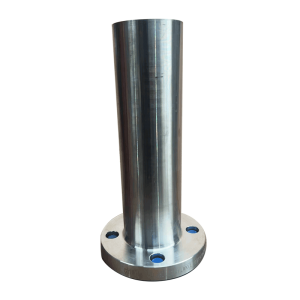

ISIPHETHO SESITULO

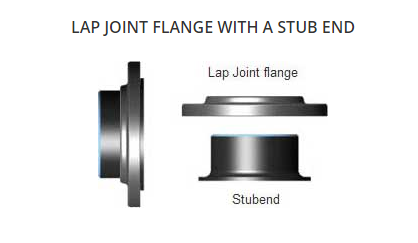

I-Stub End izosetshenziswa njalo ne-Lap Joint flange, njenge-backing flange.

Lokhu kuxhumanisa i-flange kusetshenziswa, ezinsizeni ezinomfutho ophansi kanye nezingabalulekile, futhi kuyindlela eshibhile yokufulela.

Ohlelweni lwepayipi lensimbi engagqwali, isibonelo, i-flange yensimbi yekhabhoni ingasetshenziswa, ngoba ayithinti umkhiqizo osepayipini.

Iziphetho ze-Stub zitholakala cishe kuzo zonke izinhlobo zamapayipi. Ubukhulu kanye nokubekezelelana kobukhulu kuchazwe ku-ASME B.16.9 standard. Iziphetho ze-Stub ezingamelana nokugqwala ezilula (izinto zokufakelwa) zichazwe ku-MSS SP43.

KUNGENZUZO YE-LAP JOINT FLANGE

- Inkululeko yokuzungeza ipayipi yenza kube lula ukwakheka kwezimbobo zebhawodi eziphambene.

- Ukuntuleka kokuthintana noketshezi olusepayipini kuvame ukuvumela ukusetshenziswa kwama-flange ensimbi yekhabhoni angabizi anepayipi elimelana nokugqwala.

- Ezinhlelweni eziguguleka noma ezigqwala ngokushesha, ama-flange angase agcinwe ukuze asetshenziswe kabusha.

UMBONO WEMINININGWANE YEMIKHIQIZO

1. Ubuso

ubuso obuyisicaba, i-Radius iyona ebaluleke kakhulu

2. Ngehabhu noma ngaphandle kwehabhu

3. Ukuqeda ubuso

Ukuphela ebusweni be-flange kulinganiswa njengokuphakama kwesilinganiso sobunzima be-Arithmetical (AARH). Ukuphela kunqunywa ngokwezinga elisetshenzisiwe. Isibonelo, i-ANSI B16.5 icacisa ukuqeda kobuso ngaphakathi kwebanga elingu-125AARH-500AARH (3.2Ra kuya ku-12.5Ra). Okunye ukuqeda kuyatholakala uma kufunwa, isibonelo u-1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra noma u-6.3/12.5Ra. Ububanzi obungu-3.2/6.3Ra buvame kakhulu.

UKUMAKISHA NOKUPHAKISHA

• Isendlalelo ngasinye sisebenzisa ifilimu yepulasitiki ukuvikela indawo engaphezulu

• Kuzo zonke izinsimbi ezingagqwali zipakishwa nge-plywood case. Ukuze kube ne-carbon flange enkulu zipakishwa nge-plywood pallet. Noma zingapakishwa ngendlela oyifisayo.

• Uphawu lokuthumela lungenza uma luceliwe

• Izimpawu emikhiqizweni zingabazwa noma ziphrintwe. I-OEM iyamukelwa.

UKUHLOLA

• Ukuhlolwa kwe-UT

• Ukuhlolwa kwe-PT

• Ukuhlolwa kwe-MT

• Ukuhlolwa kobukhulu

Ngaphambi kokulethwa, ithimba lethu le-QC lizohlela ukuhlolwa kwe-NDT kanye nokuhlolwa kobukhulu. Futhi lamukela i-TPI (ukuhlolwa komuntu wesithathu).

INKQUBO YOKUKHIQIZWA

| 1. Khetha izinto zokusetshenziswa zangempela | 2. Sika izinto zokusetshenziswa | 3. Ukushisa kusengaphambili |

| 4. Ukwakha | 5. Ukwelashwa ngokushisa | 6. Umshini Onzima |

| 7. Ukubhoboza | 8. Ukubumba kahle | 9. Ukumaka |

| 10. Ukuhlolwa | 11. Ukupakisha | 12. Ukulethwa |

I-flange ehambisana ne-lap idinga izingxenye ezimbili zamapayipi ohlangothini ngalunye loxhumano oluhlanganisiwe, i-stub end kanye ne-backing flange ekhululekile. I-backing flange ekhululekile ifanelana nobubanzi bangaphandle be-stub end, ehlanganiswe ngezinqe nepayipi. I-backing flange ayihlanganisiwe nepayipi, futhi ingajikeleziswa, okuwusizo kakhulu lapho kudingeka ukuqondisa ama-flange ngesikhathi sokumiswa.

Futhi, njengoba i-backing flange ingathintani noketshezi lwenqubo, ingenziwa ngezinto ezingamelani nokugqwala kakhulu. Isibonelo, uma inqubo igqwala futhi idinga ukuthi ipayipi libe ngensimbi engagqwali, njengaku-ASTM A312 TP316L, khona-ke ukuphela kwe-stub kumele kwenziwe nge-SS 316L; noma kunjalo, i-backing flange ingenziwa nge-ASTM A105 eshibhile.

Le ndlela yokuxhumanisa ayiqinile njenge-flange yentamo ye-weld kodwa ingcono kunezixhumi ezifakwe izikulufo, i-socket weld, kanye ne-slip; nokho, kubiza kakhulu ukuyisebenzisa, ngoba idinga i-full-penetration butt weld futhi idinga izingxenye ezimbili.

I-Stub End izosetshenziswa njalo ne-Lap Joint flange, njenge-backing flange.

Lokhu kuxhumanisa i-flange kusetshenziswa, ezinsizeni ezinomfutho ophansi kanye nezingabalulekile, futhi kuyindlela eshibhile yokufulela.

Ohlelweni lwepayipi lensimbi engagqwali, isibonelo, i-flange yensimbi yekhabhoni ingasetshenziswa, ngoba ayithinti umkhiqizo osepayipini.

Iziphetho ze-Stub zitholakala cishe kuzo zonke izinhlobo zamapayipi. Ubukhulu kanye nokubekezelelana kobukhulu kuchazwe ku-ASME B.16.9 standard. Iziphetho ze-Stub ezingamelana nokugqwala ezilula (izinto zokufakelwa) zichazwe ku-MSS SP43.

- Inkululeko yokuzungeza ipayipi yenza kube lula ukwakheka kwezimbobo zebhawodi eziphambene.

- Ukuntuleka kokuthintana noketshezi olusepayipini kuvame ukuvumela ukusetshenziswa kwama-flange ensimbi yekhabhoni angabizi anepayipi elimelana nokugqwala.

- Ezinhlelweni eziguguleka noma ezigqwala ngokushesha, ama-flange angase agcinwe ukuze asetshenziswe kabusha.

Imininingwane yemikhiqizo iboniswa

1. Ubuso

ubuso obuyisicaba, i-Radius iyona ebaluleke kakhulu

2. Ngehabhu noma ngaphandle kwehabhu

3. Ukuqeda ubuso

Ukuphela ebusweni be-flange kulinganiswa njengokuphakama kwesilinganiso sobunzima be-Arithmetical (AARH). Ukuphela kunqunywa ngokwezinga elisetshenzisiwe. Isibonelo, i-ANSI B16.5 icacisa ukuqeda kobuso ngaphakathi kwebanga elingu-125AARH-500AARH (3.2Ra kuya ku-12.5Ra). Okunye ukuqeda kuyatholakala uma kufunwa, isibonelo u-1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra noma u-6.3/12.5Ra. Ububanzi obungu-3.2/6.3Ra buvame kakhulu.

Ukumaka nokupakisha

• Isendlalelo ngasinye sisebenzisa ifilimu yepulasitiki ukuvikela indawo engaphezulu

• Kuzo zonke izinsimbi ezingagqwali zipakishwa nge-plywood case. Ukuze kube ne-carbon flange enkulu zipakishwa nge-plywood pallet. Noma zingapakishwa ngendlela oyifisayo.

• Uphawu lokuthumela lungenza uma luceliwe

• Izimpawu emikhiqizweni zingabazwa noma ziphrintwe. I-OEM iyamukelwa.

Ukuhlolwa

• Ukuhlolwa kwe-UT

• Ukuhlolwa kwe-PT

• Ukuhlolwa kwe-MT

• Ukuhlolwa kobukhulu

Ngaphambi kokulethwa, ithimba lethu le-QC lizohlela ukuhlolwa kwe-NDT kanye nokuhlolwa kobukhulu. Futhi lamukela i-TPI (ukuhlolwa komuntu wesithathu).

Inqubo yokukhiqiza

| 1. Khetha izinto zokusetshenziswa zangempela | 2. Sika izinto zokusetshenziswa | 3. Ukushisa kusengaphambili |

| 4. Ukwakha | 5. Ukwelashwa ngokushisa | 6. Umshini Onzima |

| 7. Ukubhoboza | 8. Ukubumba kahle | 9. Ukumaka |

| 10. Ukuhlolwa | 11. Ukupakisha | 12. Ukulethwa |

Ukufakwa kwamapayipi kuyizinto ezibalulekile ohlelweni lwamapayipi, ezisetshenziselwa ukuxhuma, ukuqondisa kabusha, ukuphambukisa, ukushintsha usayizi, ukuvala noma ukulawula ukugeleza koketshezi. Zisetshenziswa kabanzi emikhakheni efana nokwakha, imboni, amandla kanye nezinsizakalo zikamasipala.

Imisebenzi Eyinhloko:Ingenza imisebenzi efana nokuxhuma amapayipi, ukushintsha indlela yokugeleza, ukuhlukanisa nokuhlanganisa ukugeleza, ukulungisa ububanzi bamapayipi, ukuvala amapayipi, ukulawula nokulawula.

Ububanzi Bokusetshenziswa:

- Ukwakhiwa kwamanzi kanye nokukhipha amanzi:Izindololwane ze-PVC kanye ne-PPR tris zisetshenziselwa amanethiwekhi amapayipi amanzi.

- Amapayipi ezimboni:Ama-flange ensimbi engagqwali kanye nezindololwane zensimbi ezixutshwe ngomlotha zisetshenziselwa ukuthutha izinto zamakhemikhali.

- Ukuthuthwa kwamandla:Izithako zamapayipi ensimbi anomfutho ophezulu zisetshenziswa emapayipini kawoyela negesi.

- I-HVAC (Ukushisa, Umoya Ongenisayo, kanye Nomoya Ongenisayo):Izithako zamapayipi ethusi zisetshenziselwa ukuxhuma amapayipi efriji, kanti amalunga aguquguqukayo asetshenziselwa ukunciphisa ukudlidliza.

- Ukunisela ngenkasa kwezolimo:Izixhumi ezisheshayo zenza kube lula ukuhlanganiswa nokuhlukaniswa kwezinhlelo zokunisela ezifafaza.

-

I-Ansi B16.5 A105 Black Carbon Steel Slip on Flange

-

I-Flange ye-Tube Engeyona Ejwayelekile eyenziwe ngokwezifiso ...

-

I-ASME b16.48 Intengo Yemboni Yensimbi Yekhabhoni Isithombe 8 ...

-

Insimbi Engagqwali 304 304L 316 316L ASTM eyenziwe ngobumba...

-

I-Long Weld Neck Flange Standard Pressure LWN Ye ...

-

I-ANSI B16.5 Insimbi Engagqwali Ehlanganisiwe Yesokhethi Yensimbi Engagqwali ...