AMAPHARAMETHI OMKHIQIZO

| Igama Lomkhiqizo | Isivalo sepayipi |

| Usayizi | 1/2"-60" engenamthungo, 60"-110" ehlanganisiwe |

| Okujwayelekile | I-ANSI B16.9, EN10253-4, DIN2617, GOST17379, JIS B2313, MSS SP 75, njll. |

| Ubukhulu bodonga | I-SCH5S, SCH10, SCH10S ,STD, XS, SCH40S, SCH80S, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS, eyenziwe ngokwezifiso futhi njll. |

| Ukuphela | Isiphetho se-Bevel/BE/buttweld |

| Ubuso | okufakwe emanzini abandayo, ukugoqa isihlabathi, ukupholisha, ukupholisha isibuko nokunye. |

| Izinto | Insimbi engagqwali:A403 WP304/304L, A403 WP316/316L, A403 WP321, A403 WP310S, A403 WP347H, A403 WP316Ti, A403 WP317, 904L,1.4301,1.4307,1.4401,1.4571,1.4541, 254Mo njalo njalo. |

| Insimbi engagqwali ephindwe kabili:I-UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 njll. | |

| Ingxubevange ye-nickel:i-inconel600, i-inconel625, i-inconel690, i-incoloy800, i-incoloy 825, i-incoloy 800H, C22, C-276, i-Monel400, i-Alloy20 njll. | |

| Isicelo | Imboni ye-Petrochemical; imboni yezindiza kanye nezindiza; imboni yezemithi, igesi ephumayo; isitshalo samandla; isakhiwo semikhumbi; ukwelashwa kwamanzi, njll. |

| Izinzuzo | isitoko esilungile, isikhathi sokulethwa esisheshayo; sitholakala ngosayizi bonke, senziwe ngokwezifiso; ikhwalithi ephezulu |

ISIVALO SEPAYIPHI YENSIMBI

I-Steel Pipe Cap ibizwa nangokuthi i-Steel Plug, ivame ukushintshwa iye ekugcineni kwepayipi noma ifakwe entanjeni yangaphandle yesiphelo sepayipi ukuze imboze izinto ezifakwayo zepayipi. Ukuvala ipayipi ukuze umsebenzi ufane ne-pipe plug.

UHLOBO LWESIQEPHU

Ihluka kusukela ezinhlotsheni zokuxhuma, kukhona: 1. Isivalo sokushisela izinqe 2. Isivalo sokushisela izinqe

Ikepu Lensimbi le-BW

Isivalo sepayipi lensimbi le-BW uhlobo lokufakwa kwe-butt weld, izindlela zokuxhuma ukusebenzisa i-butt welding. Ngakho-ke isivalo se-BW siphela nge-beveled noma i-plain.

Ubukhulu be-BW cap kanye nesisindo:

| Usayizi wepayipi ojwayelekile | Ububanzi Be-Bevel Ngaphandle(mm) | UbudeE(mm) | Ukunciphisa Ubukhulu Bodonga Lobude, E | UbudeE1(mm) | Isisindo (kg) | |||||

| I-SCH10S | I-SCH20 | Izifo Ezithathelwana Ngocansi (STD) | I-SCH40 | XS | I-SCH80 | |||||

| 1/2 | 21.3 | 25 | 4.57 | 25 | 0.04 | 0.03 | 0.03 | 0.05 | 0.05 | |

| 3/4 | 26.7 | 25 | 3.81 | 25 | 0.06 | 0.06 | 0.06 | 0.10 | 0.10 | |

| 1 | 33.4 | 38 | 4.57 | 38 | 0.09 | 0.10 | 0.10 | 0.013 | 0.13 | |

| 1 1/4 | 42.2 | 38 | 4.83 | 38 | 0.13 | 0.14 | 0.14 | 0.20 | 0.20 | |

| 1 1/2 | 48.3 | 38 | 5.08 | 38 | 0.14 | 0.20 | 0.20 | 0.23 | 0.23 | |

| 2 | 60.3 | 38 | 5.59 | 44 | 0.20 | 0.30 | 0.30 | 0.30 | 0.30 | |

| 2 1/2 | 73 | 38 | 7.11 | 51 | 0.30 | 0.20 | 0.50 | 0.50 | 0.50 | |

| 3 | 88.9 | 51 | 7.62 | 64 | 0.45 | 0.70 | 0.70 | 0.90 | 0.90 | |

| 3 1/2 | 101.6 | 64 | 8.13 | 76 | 0.60 | 1.40 | 1.40 | 1.70 | 1.70 | |

| 4 | 114.3 | 64 | 8.64 | 76 | 0.65 | 1.6 | 1.6 | 2.0 | 2.0 | |

| 5 | 141.3 | 76 | 9.65 | 89 | 1.05 | 2.3 | 2.3 | 3.0 | 3.0 | |

| 6 | 168.3 | 89 | 10.92 | 102 | 1.4 | 3.6 | 3.6 | 4.0 | 4.0 | |

| 8 | 219.1 | 102 | 12.70 | 127 | 2.50 | 4.50 | 5.50 | 5.50 | 8.40 | 8.40 |

| 10 | 273 | 127 | 12.70 | 152 | 4.90 | 7 | 10 | 10 | 13.60 | 16.20 |

| 12 | 323.8 | 152 | 12.70 | 178 | 7 | 9 | 15 | 19 | 22 | 26.90 |

| 14 | 355.6 | 165 | 12.70 | 191 | 8.50 | 15.50 | 17 | 23 | 27 | 34.70 |

| 16 | 406.4 | 178 | 12.70 | 203 | 14.50 | 20 | 23 | 30 | 30 | 43.50 |

| 18 | 457 | 203 | 12.70 | 229 | 18 | 25 | 29 | 39 | 32 | 72.50 |

| 20 | 508 | 229 | 12.70 | 254 | 27.50 | 36 | 36 | 67 | 49 | 98.50 |

| 22 | 559 | 254 | 12.70 | 254 | 42 | 42 | 51 | 120 | ||

| 24 | 610 | 267 | 12.70 | 305 | 35 | 52 | 52 | 93 | 60 | 150 |

IZITHOMBE EZINEMINININGWANE

1. Isiphetho se-Bevel ngokwe-ANSI B16.25.

2. Ukupholisha okuqinile kuqala ngaphambi kokugoqa isihlabathi, bese ubuso buzoba bushelelezi kakhulu.

3. Ngaphandle kwe-lamination kanye nemifantu.

4. Ngaphandle kokulungiswa kokushisela.

5. Ukwelashwa kwendawo kungafakwa ku-pickled, kugoqwe ngesihlabathi, kuqedwe nge-matt, kupholishwe ngesibuko. Impela, intengo ihlukile. Ngokwesithenjwa sakho, indawo yokugoqwa kwesihlabathi ithandwa kakhulu. Intengo yokugoqwa kwesihlabathi ifanele amakhasimende amaningi.

UKUHLOLA

1. Ukulinganiswa kobukhulu, konke kungaphakathi kokubekezelelana okujwayelekile.

2. Ukubekezelelana kobukhulu: +/-12.5%, noma ngesicelo sakho.

3. I-PMI

4. Ukuhlolwa kwe-PT, UT, i-X-ray.

5. Yamukela ukuhlolwa komuntu wesithathu.

6. Nikeza isitifiketi se-MTC, i-EN10204 3.1/3.2, i-NACE

7. Umkhuba we-ASTM A262 E

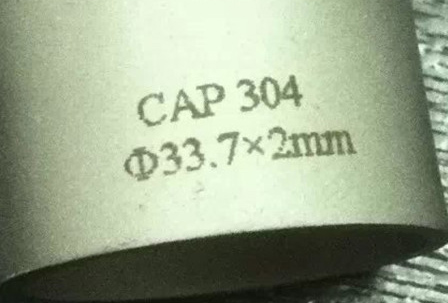

UKUPHAWULA

Imisebenzi ehlukahlukene yokumaka ingaba khona uma ucela. Siyayamukela i-LOGO yakho yokumaka.

Imibuzo Evame Ukubuzwa

1. Siyini isivalo sesitsha sokucindezela sepayipi esishiselwe ngensimbi engagqwali?

Isembozo sembozo sepayipi elicindezelwe ngensimbi engagqwali siyingxenye esetshenziselwa ukuvala iziphetho zamapayipi embozo yengcindezi axhunywe ngokushisela. Senziwe ngensimbi engagqwali, okuqinisekisa ukuqina nokumelana nokugqwala.

2. Yiziphi izinzuzo zokusebenzisa izembozo zepayipi ezicindezelwe ngensimbi engagqwali ezihlanganisiwe?

Ukusetshenziswa kwezimbozo zepayipi ezicindezelwe ngensimbi engagqwali kunezinzuzo zamandla aphezulu, ukumelana nokucindezela okuphezulu, ukumelana nokushisa okuphezulu, kanye nokumelana nokugqwala. Kuqinisekisa ukuvalwa okuphephile futhi kusiza ukugcina ubuqotho bomkhumbi ocindezelwe.

3. Ungasifaka kanjani isembozo sesitsha sokucindezela sepayipi esishiselwe ngensimbi engagqwali?

Ukuze ufake isivalo sesitsha sokucindezela sepayipi elingagqwali esishisiwe ngensimbi engagqwali, sebenzisa amasu okushisela afanele ukushisela isivalo ekugcineni kwepayipi lesitsha sokucindezela. Kubalulekile ukuqinisekisa ukuhambisana okufanele kanye nokushisela okuqinile ukuze kuqinisekiswe ukuvalwa okuthembekile.

4. Ingabe izimbozo zepayipi ezicindezelwe ngensimbi engagqwali ziyatholakala ngobukhulu obuhlukene?

Yebo, izembozo zemikhumbi yokucindezela yepayipi ehlanganisiwe ngensimbi engagqwali ziyatholakala ngobukhulu obuhlukene ukuze zivumelane nobubanzi obuhlukahlukene bepayipi. Ukukhetha usayizi ofanele ukuqinisekisa ukulingana okufanele kanye nokuvala kubalulekile.

5. Ingabe izimbozo zemikhumbi yokucindezela yepayipi ehlanganisiwe yensimbi engagqwali zingasetshenziswa ezinhlotsheni ezisebenzisa umfutho ophezulu?

Yebo, izembozo zemikhumbi yokucindezela yepayipi ehlanganisiwe ngensimbi engagqwali zenzelwe ukumelana nokusetshenziswa komfutho ophezulu. Zakhelwe ukumelana namandla abangelwa umfutho ngaphakathi kwesitsha futhi zigcine ukuvalwa okuqinile.

6. Ingabe isimbozo sepayipi elicindezelwe ngensimbi engagqwali asimelani nokugqwala?

Yebo, izembozo zemikhumbi yepayipi ecindezelwe ngensimbi engagqwali zimelana kakhulu nokugqwala. Insimbi engagqwali yaziwa ngezakhiwo zayo ezimelana nokugqwala, okwenza ifaneleke ezinhlotsheni ezahlukahlukene zezimboni.

7. Ingabe izimbozo zemibhobho yokucindezela yensimbi engagqwali ehlanganisiwe zingasetshenziswa nezinhlobo ezahlukene zemibhobho yokucindezela?

Yebo, izembozo zemikhumbi yokucindezela yepayipi ehlanganisiwe ngensimbi engagqwali ziyasebenziseka futhi zingasetshenziswa nezinhlobo ezahlukene zemikhumbi yokucindezela, okuhlanganisa naleyo esetshenziswa embonini kawoyela negesi, amakhemikhali kanye nemithi.

8. Ingakanani impilo yenkonzo yesembozo sesitsha sokucindezela sepayipi esishisiwe ngensimbi engagqwali?

Isikhathi senkonzo yezivalo zepayipi ezihlanganisiwe zensimbi engagqwali sincike ezicini ezifana nezimo zokusetshenziswa kwesivalo, ukugcinwa kanye nekhwalithi. Ngokunakekelwa okufanele nokuhlolwa okuvamile, zingahlala iminyaka eminingi.

9. Ingabe zikhona yini izinyathelo zokuphepha ezithile uma usebenzisa izembozo zemibhobho yokucindezela yensimbi engagqwali ehlanganisiwe?

Uma usebenzisa izembozo zemibhobho yokucindezela yensimbi engagqwali ehlanganisiwe, kufanele kulandelwe izinyathelo zokuphepha, njengokusebenzisa amasu afanele okushisela ukuqinisekisa ukuvala okuqinile nokungavuzi. Ukuze uqinisekise ukuphepha, udinga futhi ukuhlola njalo izimpawu zokuguguleka noma zomonakalo.

10. Ingabe isembozo sesitsha sokucindezela sepayipi esishiselwe ngensimbi engagqwali singenziwa ngokwezifiso?

Yebo, kuye ngomkhiqizi, izembozo zemikhumbi yokucindezela yepayipi ehlanganisiwe ngensimbi engagqwali zingenziwa ngokwezifiso ukuze zihlangabezane nezidingo ezithile. Izinketho zokwenza ngokwezifiso zingafaka izinto ezahlukene, osayizi kanye nemiklamo ukuze ivumelane nezicelo ngazinye.

Ukufakwa kwamapayipi kuyizinto ezibalulekile ohlelweni lwamapayipi, ezisetshenziselwa ukuxhuma, ukuqondisa kabusha, ukuphambukisa, ukushintsha usayizi, ukuvala noma ukulawula ukugeleza koketshezi. Zisetshenziswa kabanzi emikhakheni efana nokwakha, imboni, amandla kanye nezinsizakalo zikamasipala.

Imisebenzi Eyinhloko:Ingenza imisebenzi efana nokuxhuma amapayipi, ukushintsha indlela yokugeleza, ukuhlukanisa nokuhlanganisa ukugeleza, ukulungisa ububanzi bamapayipi, ukuvala amapayipi, ukulawula nokulawula.

Ububanzi Bokusetshenziswa:

- Ukwakhiwa kwamanzi kanye nokukhipha amanzi:Izindololwane ze-PVC kanye ne-PPR tris zisetshenziselwa amanethiwekhi amapayipi amanzi.

- Amapayipi ezimboni:Ama-flange ensimbi engagqwali kanye nezindololwane zensimbi ezixutshwe ngomlotha zisetshenziselwa ukuthutha izinto zamakhemikhali.

- Ukuthuthwa kwamandla:Izithako zamapayipi ensimbi anomfutho ophezulu zisetshenziswa emapayipini kawoyela negesi.

- I-HVAC (Ukushisa, Umoya Ongenisayo, kanye Nomoya Ongenisayo):Izithako zamapayipi ethusi zisetshenziselwa ukuxhuma amapayipi efriji, kanti amalunga aguquguqukayo asetshenziselwa ukunciphisa ukudlidliza.

- Ukunisela ngenkasa kwezolimo:Izixhumi ezisheshayo zenza kube lula ukuhlanganiswa nokuhlukaniswa kwezinhlelo zokunisela ezifafaza.

-

I-ASME B16.9 A105 A234WPB Insimbi yekhabhoni efakwe isinqe ...

-

Insimbi Engagqwali A403 WP316 Butt Weld Pipe Fitti ...

-

isiphetho se-carbon steel sch80 butt esihlanganisiwe esingu-12 intshi sch4...

-

insimbi yekhabhoni enciphileyo yokunciphisa i-ASTM A105 Emnyama ...

-

I-90 degree endololwaneni tee reducer carbon steel Butt w ...

-

Ipayipi lendololwane elingu-1″ 33.4mm DN25 25A sch10 elihambisanayo...