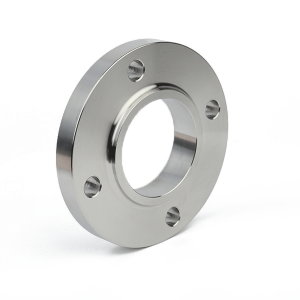

ISICELO

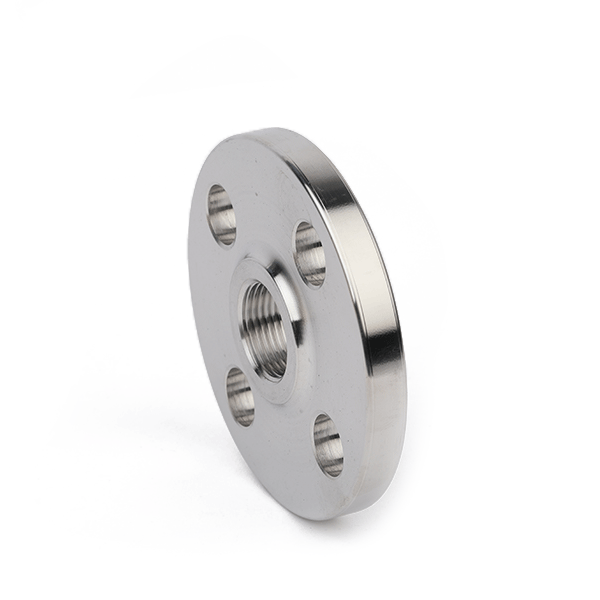

| Igama Lomkhiqizo | I-flange yentambo |

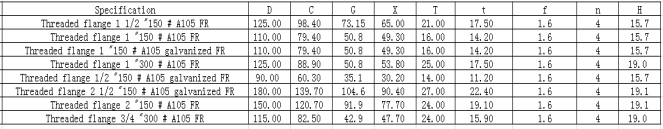

| Usayizi | 1/2"-24" |

| Ingcindezi | 150#-2500#,PN0.6-PN400,5K-40K |

| Okujwayelekile | I-ANSI B16.5, EN1092-1, JIS B2220 njll. |

| Uhlobo olunentambo | I-NPT, i-BSP |

| Izinto | Insimbi engagqwali:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo njalo njalo. |

| Insimbi yekhabhoni:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 njll. | |

| Insimbi engagqwali ephindwe kabili:I-UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 njll. | |

| Insimbi yepayipi:I-A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 njll. | |

| Ingxubevange ye-nickel:i-inconel600, i-inconel625, i-inconel690, i-incoloy800, i-incoloy 825, i-incoloy 800H,C22, C-276, i-Monel400, i-Alloy20 njll. | |

| Ingxubevange ye-Cr-Mo:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, njll. | |

| Isicelo | Imboni ye-Petrochemical; imboni yezindiza kanye nezindiza; imboni yemithi; ukukhishwa kwegesi; isitshalo samandla; isakhiwo semikhumbi; ukwelashwa kwamanzi, njll. |

| Izinzuzo | isitoko esilungile, isikhathi sokulethwa esisheshayo; sitholakala ngosayizi bonke, senziwe ngokwezifiso; ikhwalithi ephezulu |

AMAZINGA OKUDINGEKA

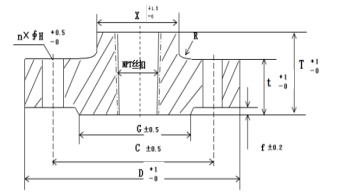

UMBONO WEMINININGWANE YEMIKHIQIZO

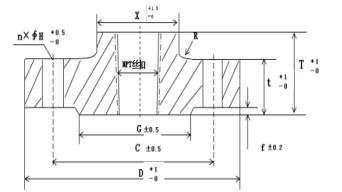

1. Ubuso

Kungaba ubuso obuphakanyisiwe (RF), ubuso obugcwele (FF), i-Ring joint (RTJ), i-Groove, ulimi, noma kwenziwe ngokwezifiso.

2. Ingxoxo

I-NPT noma i-BSP

3. I-CNC fine iqediwe

Ukuphela kobuso: Ukuphela kobuso be-flange kulinganiswa njengokuphakama kwesilinganiso sobunzima be-Arithmetical (AARH). Ukuphela kunqunywa ngokwezinga elisetshenzisiwe. Isibonelo, i-ANSI B16.5 icacisa ukuqeda kobuso ngaphakathi kwebanga elingu-125AARH-500AARH (3.2Ra kuya ku-12.5Ra). Okunye ukuqeda kuyatholakala uma kufunwa, isibonelo u-1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra noma u-6.3/12.5Ra. Ububanzi obungu-3.2/6.3Ra buvame kakhulu.

UKUMAKISHA NOKUPHAKISHA

• Isendlalelo ngasinye sisebenzisa ifilimu yepulasitiki ukuvikela indawo engaphezulu

• Kuzo zonke izinsimbi ezingagqwali zipakishwa nge-plywood case. Ukuze kube ne-carbon flange enkulu zipakishwa nge-plywood pallet. Noma zingapakishwa ngendlela oyifisayo.

• Uphawu lokuthumela lungenza uma luceliwe

• Izimpawu emikhiqizweni zingabazwa noma ziphrintwe. I-OEM iyamukelwa.

UKUHLOLA

• Ukuhlolwa kwe-UT

• Ukuhlolwa kwe-PT

• Ukuhlolwa kwe-MT

• Ukuhlolwa kobukhulu

Ngaphambi kokulethwa, ithimba lethu le-QC lizohlela ukuhlolwa kwe-NDT kanye nokuhlolwa kobukhulu.Futhi yamukela i-TPI (ukuhlolwa komuntu wesithathu).

INKQUBO YOKUKHIQIZWA

| 1. Khetha izinto zokusetshenziswa zangempela | 2. Sika izinto zokusetshenziswa | 3. Ukushisa kusengaphambili |

| 4. Ukwakha | 5. Ukwelashwa ngokushisa | 6. Umshini Onzima |

| 7. Ukubhoboza | 8. Ukubumba kahle | 9. Ukumaka |

| 10. Ukuhlolwa | 11. Ukupakisha | 12. Ukulethwa |

ICALA LOKUBAMBISANA

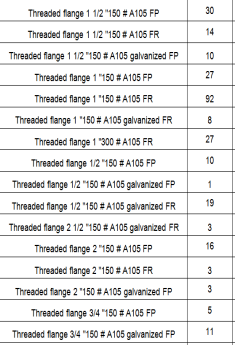

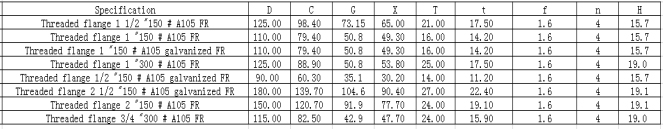

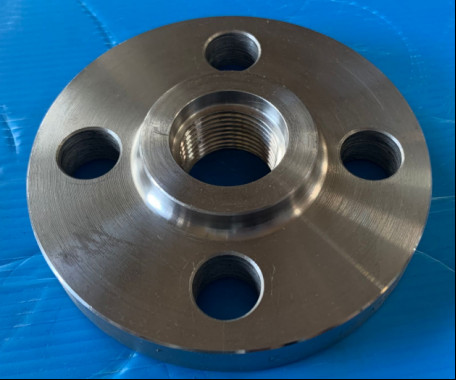

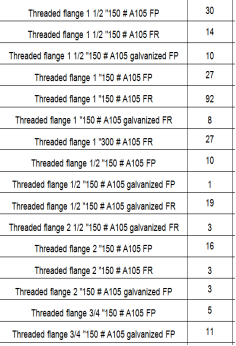

Lo msebenzi weBrazil. Ezinye izinto zidinga uwoyela wokulwa nokugqwala kanti ezinye zidinga ukugqoka nge-galvanized.

Imibuzo Evame Ukubuzwa

1. Iyini insimbi engagqwali 304?

Insimbi engagqwali engu-304 iyinsimbi engagqwali evame ukusetshenziswa kakhulu enokugqwala okuhle kakhulu, amandla aphezulu kanye nokwakheka okuhle. Isetshenziswa kabanzi ezimbonini ezahlukahlukene ngenxa yokuguquguquka kwayo kanye nokuqina kwayo.

2. Iyini insimbi engagqwali engu-304L?

Insimbi engagqwali i-304L iyinhlobo yensimbi engagqwali ephansi yekhabhoni. Inikeza ukushibilika okuthuthukisiwe ngenkathi igcina ukumelana nokugqwala okufanayo kanye nezakhiwo zemishini. Leli banga livame ukusetshenziswa ezinhlelweni ezidinga ukushibilika.

3. Iyini insimbi engagqwali 316?

Insimbi engagqwali engu-316 iyi-alloy yensimbi engagqwali e-austenitic equkethe i-molybdenum ukuze ithuthukise ukumelana kwayo nokugqwala ezindaweni zasolwandle kanye ne-chloride. Inamandla amahle kakhulu kanye nokumelana okuphezulu kokukhasa, okwenza ifaneleke ezinhlotsheni ezahlukahlukene zezicelo ezidinga amandla.

4. Iyini insimbi engagqwali engu-316L?

Insimbi engagqwali engu-316L iyinhlobo yensimbi engagqwali engu-316 enekhabhoni ephansi. Ithuthukise ukushibilika kanye nokumelana nokugqwala kwe-intergranular. Leli banga livame ukusetshenziswa ezinhlotsheni ezidinga ukumelana nokugqwala okuphezulu kanye nokwakheka okuhle kakhulu.

5. Ziyini izinto zokufaka amapayipi ahlanganiswe ngentambo?

Izithako zamapayipi ezihlanganisiwe ziyizithako zamapayipi ezenziwe ngokwakha insimbi eshisayo nokusebenzisa amandla omshini ukuze ziguqulwe zibe yisimo esifunwayo. Lezi zithako zinezintambo ebusweni bangaphandle futhi zingaxhunywa kalula epayipini elihlanganisiwe ukuze kuxhunywe okuphephile, okungavuzi.

6. Iyini i-flange?

I-flange iwumphetho wangaphandle noma wangaphakathi osetshenziselwa ukuqinisa noma ukuxhuma amapayipi, ama-valve, noma ezinye izingxenye ohlelweni lwamapayipi. Zinikeza indlela elula yokuhlanganisa, ukuqaqa nokugcina uhlelo. Ama-flange ensimbi engagqwali anokumelana okuhle kakhulu nokugqwala futhi angamelana nokushisa okuphezulu.

7. Yiziphi izindinganiso ze-ASTM zokufakelwa okunezintambo kanye nama-flange ahlanganisiwe?

Izindinganiso ze-ASTM ziyizindinganiso eziqashelwa emhlabeni wonke ezithuthukiswe yi-American Society for Testing and Materials. Lezi zindinganiso ziqinisekisa ukuthi ukufakwa kwezintambo kanye nama-flange ahlanganisiwe ahlangabezana nezidingo ezithile zokwakheka kwezinto, ubukhulu, izakhiwo zemishini kanye nezinqubo zokuhlola.

8. Yiziphi izinzuzo zokusebenzisa izinsimbi zokufaka ipayipi ezihlanganiswe ngensimbi engagqwali kanye nama-flange?

Izithako zamapayipi ezenziwe ngentambo ezihlanganisiwe zensimbi engagqwali kanye nama-flange anikeza izinzuzo ezahlukahlukene, okuhlanganisa ukumelana nokugqwala okuhle kakhulu, amandla aphezulu, ukuqina kanye nokuguquguquka. Zingamelana namazinga okushisa aphezulu, ukucindezeleka kanye nezimo ezinzima, okwenza zifaneleke ezinhlotsheni eziningi zezicelo.

9. Kukuziphi izinkambu lapho kusetshenziswa khona izinto zokufaka amapayipi ezenziwe ngensimbi engagqwali kanye nama-flange ajwayelekile?

Lezi zinto zokufaka kanye nama-flange zisetshenziswa kabanzi ezimbonini ezifana namafutha negesi, i-petrochemical, amakhemikhali, ukukhiqizwa kukagesi, imithi, i-pulp nephepha, ukucubungula ukudla kanye nokwelashwa kwamanzi. Zivame ukusetshenziswa ezinhlelweni zamapayipi, amapayipi, izindawo zokuhluza kanye nezinye izinhlelo zokusebenza lapho kudingeka khona ukuxhumeka okuphephile nokusebenza okuthembekile.

10. Ungakhetha kanjani izinsimbi zokufakelwa zamapayipi ezihlanganisiwe ezenziwe ngensimbi engagqwali kanye nama-flange afanele?

Ukuze ukhethe izinto zokufaka nama-flange afanele, cabangela izici ezifana nezidingo zokusetshenziswa, izimo zokusebenza (izinga lokushisa, ingcindezi, kanye nezindawo ezigqwalisayo), usayizi wepayipi, kanye nokuhambisana noketshezi oluthuthwayo. Kunconywa ukuthi uthintane nomhlinzeki onolwazi noma unjiniyela ukuze uthole isiqondiso sokukhetha izinto zokufaka nama-flange afanele izidingo zakho ezithile.

Imininingwane yemikhiqizo iboniswa

1. Ubuso

Kungaba ubuso obuphakanyisiwe (RF), ubuso obugcwele (FF), i-Ring joint (RTJ), i-Groove, ulimi, noma kwenziwe ngokwezifiso.

2. Ingxoxo

I-NPT noma i-BSP

3. I-CNC fine iqediwe

Ukuphela kobuso: Ukuphela kobuso be-flange kulinganiswa njengokuphakama kwesilinganiso sobunzima be-Arithmetical (AARH). Ukuphela kunqunywa ngokwezinga elisetshenzisiwe. Isibonelo, i-ANSI B16.5 icacisa ukuqeda kobuso ngaphakathi kwebanga elingu-125AARH-500AARH (3.2Ra kuya ku-12.5Ra). Okunye ukuqeda kuyatholakala uma kufunwa, isibonelo u-1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra noma u-6.3/12.5Ra. Ububanzi obungu-3.2/6.3Ra buvame kakhulu.

Ukumaka nokupakisha

• Isendlalelo ngasinye sisebenzisa ifilimu yepulasitiki ukuvikela indawo engaphezulu

• Kuzo zonke izinsimbi ezingagqwali zipakishwa nge-plywood case. Ukuze kube ne-carbon flange enkulu zipakishwa nge-plywood pallet. Noma zingapakishwa ngendlela oyifisayo.

• Uphawu lokuthumela lungenza uma luceliwe

• Izimpawu emikhiqizweni zingabazwa noma ziphrintwe. I-OEM iyamukelwa.

Ukuhlolwa

• Ukuhlolwa kwe-UT

• Ukuhlolwa kwe-PT

• Ukuhlolwa kwe-MT

• Ukuhlolwa kobukhulu

Ngaphambi kokulethwa, ithimba lethu le-QC lizohlela ukuhlolwa kwe-NDT kanye nokuhlolwa kobukhulu. Futhi lamukela i-TPI (ukuhlolwa komuntu wesithathu).

Inqubo yokukhiqiza

| 1. Khetha izinto zokusetshenziswa zangempela | 2. Sika izinto zokusetshenziswa | 3. Ukushisa kusengaphambili |

| 4. Ukwakha | 5. Ukwelashwa ngokushisa | 6. Umshini Onzima |

| 7. Ukubhoboza | 8. Ukubumba kahle | 9. Ukumaka |

| 10. Ukuhlolwa | 11. Ukupakisha | 12. Ukulethwa |

Icala Lokubambisana

Lo msebenzi weBrazil. Ezinye izinto zidinga uwoyela wokulwa nokugqwala kanti ezinye zidinga ukugqoka nge-galvanized.

Ukufakwa kwamapayipi kuyizinto ezibalulekile ohlelweni lwamapayipi, ezisetshenziselwa ukuxhuma, ukuqondisa kabusha, ukuphambukisa, ukushintsha usayizi, ukuvala noma ukulawula ukugeleza koketshezi. Zisetshenziswa kabanzi emikhakheni efana nokwakha, imboni, amandla kanye nezinsizakalo zikamasipala.

Imisebenzi Eyinhloko:Ingenza imisebenzi efana nokuxhuma amapayipi, ukushintsha indlela yokugeleza, ukuhlukanisa nokuhlanganisa ukugeleza, ukulungisa ububanzi bamapayipi, ukuvala amapayipi, ukulawula nokulawula.

Ububanzi Bokusetshenziswa:

- Ukwakhiwa kwamanzi kanye nokukhipha amanzi:Izindololwane ze-PVC kanye ne-PPR tris zisetshenziselwa amanethiwekhi amapayipi amanzi.

- Amapayipi ezimboni:Ama-flange ensimbi engagqwali kanye nezindololwane zensimbi ezixutshwe ngomlotha zisetshenziselwa ukuthutha izinto zamakhemikhali.

- Ukuthuthwa kwamandla:Izithako zamapayipi ensimbi anomfutho ophezulu zisetshenziswa emapayipini kawoyela negesi.

- I-HVAC (Ukushisa, Umoya Ongenisayo, kanye Nomoya Ongenisayo):Izithako zamapayipi ethusi zisetshenziselwa ukuxhuma amapayipi efriji, kanti amalunga aguquguqukayo asetshenziselwa ukunciphisa ukudlidliza.

- Ukunisela ngenkasa kwezolimo:Izixhumi ezisheshayo zenza kube lula ukuhlanganiswa nokuhlukaniswa kwezinhlelo zokunisela ezifafaza.

-

I-Stainle Ehlanganisiwe Ye-Orifice Ejwayelekile Yokucindezela ...

-

I-Flange ANSI/ASME/JIS Standard Carbon eyenziwe ngokwezifiso ...

-

I-ANSI DIN Forged Class150 Stainless Steel Slip o ...

-

I-Din dn800 flange en10921 pn40 pn6 carbon steel ...

-

Isikulufa se-BSP DIN PN 10/16 carbon steel A105 flange ...

-

insimbi engagqwali eyakhiwe nge-flange ehlanganisiwe evulekile c ...