AMAPHARAMETHI OMKHIQIZO

| Igama Lomkhiqizo | Isivalo sepayipi |

| Usayizi | 1/2"-60" engenamthungo, 60"-110" ehlanganisiwe |

| Okujwayelekile | I-ANSI B16.9, EN10253-4, DIN2617, GOST17379, JIS B2313, MSS SP 75, njll. |

| Ubukhulu bodonga | I-SCH5S, SCH10, SCH10S ,STD, XS, SCH40S, SCH80S, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS, eyenziwe ngokwezifiso futhi njll. |

| Ukuphela | Isiphetho se-Bevel/BE/buttweld |

| Ubuso | okufakwe emanzini abandayo, ukugoqa isihlabathi, ukupholisha, ukupholisha isibuko nokunye. |

| Izinto | Insimbi engagqwali:A403 WP304/304L, A403 WP316/316L, A403 WP321, A403 WP310S, A403 WP347H, A403 WP316Ti, A403 WP317, 904L,1.4301,1.4307,1.4401,1.4571,1.4541, 254Mo njalo njalo. |

| Insimbi engagqwali ephindwe kabili:I-UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 njll. | |

| Ingxubevange ye-nickel:i-inconel600, i-inconel625, i-inconel690, i-incoloy800, i-incoloy 825, i-incoloy 800H, C22, C-276, i-Monel400, i-Alloy20 njll. | |

| Isicelo | Imboni ye-Petrochemical; imboni yezindiza kanye nezindiza; imboni yezemithi, igesi ephumayo; isitshalo samandla; isakhiwo semikhumbi; ukwelashwa kwamanzi, njll. |

| Izinzuzo | isitoko esilungile, isikhathi sokulethwa esisheshayo; sitholakala ngosayizi bonke, senziwe ngokwezifiso; ikhwalithi ephezulu |

ISIVALO SEPAYIPHI YENSIMBI

I-Steel Pipe Cap ibizwa nangokuthi i-Steel Plug, ivame ukushintshwa iye ekugcineni kwepayipi noma ifakwe entanjeni yangaphandle yesiphelo sepayipi ukuze imboze izinto ezifakwayo zepayipi. Ukuvala ipayipi ukuze umsebenzi ufane ne-pipe plug.

UHLOBO LWESIQEPHU

Ihluka kusukela ezinhlotsheni zokuxhuma, kukhona: 1. Isivalo sokushisela izinqe 2. Isivalo sokushisela izinqe

Ikepu Lensimbi le-BW

Isivalo sepayipi lensimbi le-BW uhlobo lokufakwa kwe-butt weld, izindlela zokuxhuma ukusebenzisa i-butt welding. Ngakho-ke isivalo se-BW siphela nge-beveled noma i-plain.

Ubukhulu be-BW cap kanye nesisindo:

| Usayizi wepayipi ojwayelekile | Ububanzi Be-Bevel Ngaphandle(mm) | UbudeE(mm) | Ukunciphisa Ubukhulu Bodonga Lobude, E | UbudeE1(mm) | Isisindo (kg) | |||||

| I-SCH10S | I-SCH20 | Izifo ezithathelwana ngocansi (STD) | I-SCH40 | XS | I-SCH80 | |||||

| 1/2 | 21.3 | 25 | 4.57 | 25 | 0.04 | 0.03 | 0.03 | 0.05 | 0.05 | |

| 3/4 | 26.7 | 25 | 3.81 | 25 | 0.06 | 0.06 | 0.06 | 0.10 | 0.10 | |

| 1 | 33.4 | 38 | 4.57 | 38 | 0.09 | 0.10 | 0.10 | 0.013 | 0.13 | |

| 1 1/4 | 42.2 | 38 | 4.83 | 38 | 0.13 | 0.14 | 0.14 | 0.20 | 0.20 | |

| 1 1/2 | 48.3 | 38 | 5.08 | 38 | 0.14 | 0.20 | 0.20 | 0.23 | 0.23 | |

| 2 | 60.3 | 38 | 5.59 | 44 | 0.20 | 0.30 | 0.30 | 0.30 | 0.30 | |

| 2 1/2 | 73 | 38 | 7.11 | 51 | 0.30 | 0.20 | 0.50 | 0.50 | 0.50 | |

| 3 | 88.9 | 51 | 7.62 | 64 | 0.45 | 0.70 | 0.70 | 0.90 | 0.90 | |

| 3 1/2 | 101.6 | 64 | 8.13 | 76 | 0.60 | 1.40 | 1.40 | 1.70 | 1.70 | |

| 4 | 114.3 | 64 | 8.64 | 76 | 0.65 | 1.6 | 1.6 | 2.0 | 2.0 | |

| 5 | 141.3 | 76 | 9.65 | 89 | 1.05 | 2.3 | 2.3 | 3.0 | 3.0 | |

| 6 | 168.3 | 89 | 10.92 | 102 | 1.4 | 3.6 | 3.6 | 4.0 | 4.0 | |

| 8 | 219.1 | 102 | 12.70 | 127 | 2.50 | 4.50 | 5.50 | 5.50 | 8.40 | 8.40 |

| 10 | 273 | 127 | 12.70 | 152 | 4.90 | 7 | 10 | 10 | 13.60 | 16.20 |

| 12 | 323.8 | 152 | 12.70 | 178 | 7 | 9 | 15 | 19 | 22 | 26.90 |

| 14 | 355.6 | 165 | 12.70 | 191 | 8.50 | 15.50 | 17 | 23 | 27 | 34.70 |

| 16 | 406.4 | 178 | 12.70 | 203 | 14.50 | 20 | 23 | 30 | 30 | 43.50 |

| 18 | 457 | 203 | 12.70 | 229 | 18 | 25 | 29 | 39 | 32 | 72.50 |

| 20 | 508 | 229 | 12.70 | 254 | 27.50 | 36 | 36 | 67 | 49 | 98.50 |

| 22 | 559 | 254 | 12.70 | 254 | 42 | 42 | 51 | 120 | ||

| 24 | 610 | 267 | 12.70 | 305 | 35 | 52 | 52 | 93 | 60 | 150 |

IZITHOMBE EZINEMINININGWANE

1. Isiphetho se-Bevel ngokwe-ANSI B16.25.

2. Ukupholisha okuqinile kuqala ngaphambi kokugoqa isihlabathi, bese ubuso buzoba bushelelezi kakhulu.

3. Ngaphandle kwe-lamination kanye nemifantu.

4. Ngaphandle kokulungiswa kokushisela.

5. Ukwelashwa kwendawo kungafakwa ku-pickled, kugoqwe ngesihlabathi, kuqedwe nge-matt, kupholishwe ngesibuko. Impela, intengo ihlukile. Ngokwesithenjwa sakho, indawo yokugoqwa kwesihlabathi ithandwa kakhulu. Intengo yokugoqwa kwesihlabathi ifanele amakhasimende amaningi.

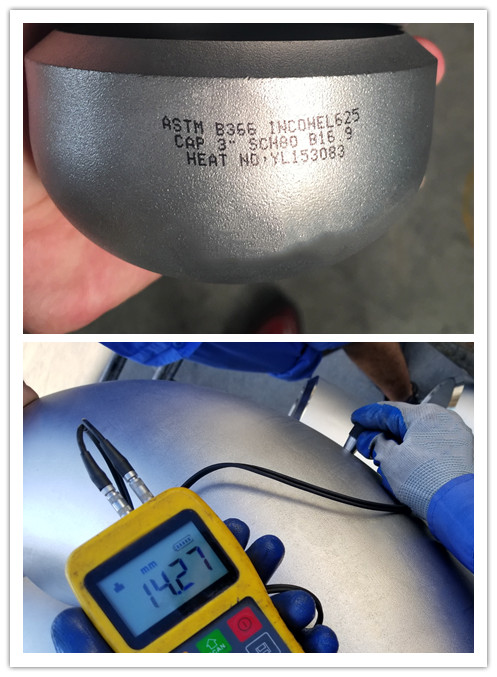

UKUHLOLA

1. Ukulinganiswa kobukhulu, konke kungaphakathi kokubekezelelana okujwayelekile.

2. Ukubekezelelana kobukhulu: +/-12.5%, noma ngesicelo sakho.

3. I-PMI

4. Ukuhlolwa kwe-PT, UT, i-X-ray.

5. Yamukela ukuhlolwa komuntu wesithathu.

6. Nikeza isitifiketi se-MTC, i-EN10204 3.1/3.2, i-NACE

7. Umkhuba we-ASTM A262 E

UKUPHAWULA

Imisebenzi ehlukahlukene yokumaka ingaba khona uma ucela. Siyayamukela i-LOGO yakho yokumaka.

I-Steel Pipe Cap ibizwa nangokuthi i-Steel Plug, ivame ukushintshwa iye ekugcineni kwepayipi noma ifakwe entanjeni yangaphandle yesiphelo sepayipi ukuze imboze izinto ezifakwayo zepayipi. Ukuvala ipayipi ukuze umsebenzi ufane ne-pipe plug.

Ihluka kusukela ezinhlotsheni zokuxhuma, kukhona: 1. Isivalo sokushisela izinqe 2. Isivalo sokushisela izinqe

Ikepu Lensimbi le-BW

Isivalo sepayipi lensimbi le-BW uhlobo lokufakwa kwe-butt weld, izindlela zokuxhuma ukusebenzisa i-butt welding. Ngakho-ke isivalo se-BW siphela nge-beveled noma i-plain.

Ubukhulu be-BW cap kanye nesisindo:

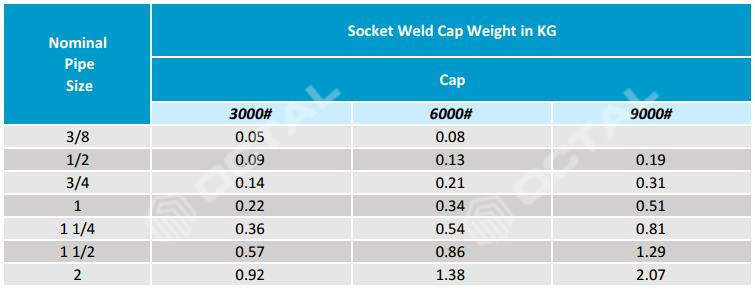

I-Socket Weld Steel Pipe Cap

Isivalo sokushisela i-socket siwukuxhuma amapayipi nezivalo ngokufaka ipayipi endaweni yamahlombe okufinyelela esivalo sokushisela i-socket.

Ubukhulu be-SW cap kanye nesisindo:

Izithombe ezinemininingwane

1. Isiphetho se-Bevel ngokwe-ANSI B16.25.

2. Ukupholisha okuqinile kuqala ngaphambi kokugoqa isihlabathi, bese ubuso buzoba bushelelezi kakhulu.

3. Ngaphandle kwe-lamination kanye nemifantu.

4. Ngaphandle kokulungiswa kokushisela.

5. Ukwelashwa kwendawo kungafakwa ku-pickled, kugoqwe ngesihlabathi, kuqedwe nge-matt, kupholishwe ngesibuko. Impela, intengo ihlukile. Ngokwesithenjwa sakho, indawo yokugoqwa kwesihlabathi ithandwa kakhulu. Intengo yokugoqwa kwesihlabathi ifanele amakhasimende amaningi.

Ukuhlolwa

1. Ukulinganiswa kobukhulu, konke kungaphakathi kokubekezelelana okujwayelekile.

2. Ukubekezelelana kobukhulu: +/-12.5%, noma ngesicelo sakho.

3. I-PMI

4. Ukuhlolwa kwe-PT, UT, i-X-ray.

5. Yamukela ukuhlolwa komuntu wesithathu.

6. Nikeza isitifiketi se-MTC, i-EN10204 3.1/3.2, i-NACE

7. Umkhuba we-ASTM A262 E

Ukumaka

Imisebenzi ehlukahlukene yokumaka ingaba khona uma ucela. Siyayamukela i-LOGO yakho yokumaka.

Ukupakisha Nokuthumela

1. Ipakishwe nge-plywood case noma i-plywood pallet

2. sizobeka uhlu lokupakisha kuphakheji ngayinye

3. sizobeka izimpawu zokuthumela kuphakheji ngayinye. Amagama ezimpawu akhona ngokwesicelo sakho.

4. Zonke izinto zokupakisha izinkuni azinawo uphethiloli

Ukufakwa kwamapayipi kuyizinto ezibalulekile ohlelweni lwamapayipi, ezisetshenziselwa ukuxhuma, ukuqondisa kabusha, ukuphambukisa, ukushintsha usayizi, ukuvala noma ukulawula ukugeleza koketshezi. Zisetshenziswa kabanzi emikhakheni efana nokwakha, imboni, amandla kanye nezinsizakalo zikamasipala.

Imisebenzi Eyinhloko:Ingenza imisebenzi efana nokuxhuma amapayipi, ukushintsha indlela yokugeleza, ukuhlukanisa nokuhlanganisa ukugeleza, ukulungisa ububanzi bamapayipi, ukuvala amapayipi, ukulawula nokulawula.

Ububanzi Bokusetshenziswa:

- Ukwakhiwa kwamanzi kanye nokukhipha amanzi:Izindololwane ze-PVC kanye ne-PPR tris zisetshenziselwa amanethiwekhi amapayipi amanzi.

- Amapayipi ezimboni:Ama-flange ensimbi engagqwali kanye nezindololwane zensimbi ezixutshwe ngomlotha zisetshenziselwa ukuthutha izinto zamakhemikhali.

- Ukuthuthwa kwamandla:Izithako zamapayipi ensimbi anomfutho ophezulu zisetshenziswa emapayipini kawoyela negesi.

- I-HVAC (Ukushisa, Umoya Ongenisayo, kanye Nomoya Ongenisayo):Izithako zamapayipi ethusi zisetshenziselwa ukuxhuma amapayipi efriji, kanti amalunga aguquguqukayo asetshenziselwa ukunciphisa ukudlidliza.

- Ukunisela ngenkasa kwezolimo:Izixhumi ezisheshayo zenza kube lula ukuhlanganiswa nokuhlukaniswa kwezinhlelo zokunisela ezifafaza.

-

insimbi yekhabhoni A105 A234 WPB ANSI B16.49 3d 30 45...

-

I-ASME B16.9 A105 A234WPB Insimbi yekhabhoni efakwe isinqe ...

-

Izithako ze-SUS304 316 ze-Stainless Steel Butt-Weld B...

-

insimbi yekhabhoni engu-45 degree bend 3d bw 12.7mm WT AP...

-

Insimbi ye-DN500 engamasentimitha angu-20 ye-Alloy A234 WP22 engenamthungo engu-90...

-

I-A234WPB ANSI B16.9 Pipe Fitting Elbow Alloy Ste ...